Control Plans

It defines What to Inspect, How to Inspect, Method of Inspection and the Pass / Fail CriteriaThe Inspection Requirements for specific Part Number, Revision and Router Operation Step can be defined using Control Plans.

Control Plans Core Features

Control Plans are Copied and Linked to Each Inspection record when it exists. Inspectors Complete the Inspection Requirement report and Determine the Lot Results – Pass / Fail.

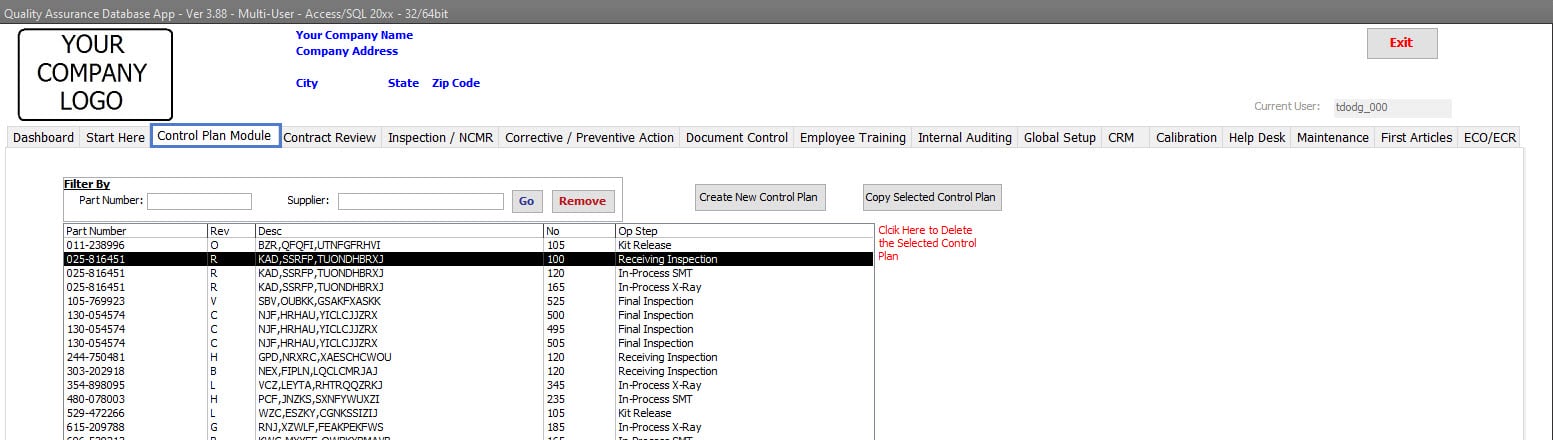

| Control Plan View

Control Plans can be Searched using the Various Filters available. Single-Click operation to View Existing Control Plan Details and to Start a New Control Plan. |

|

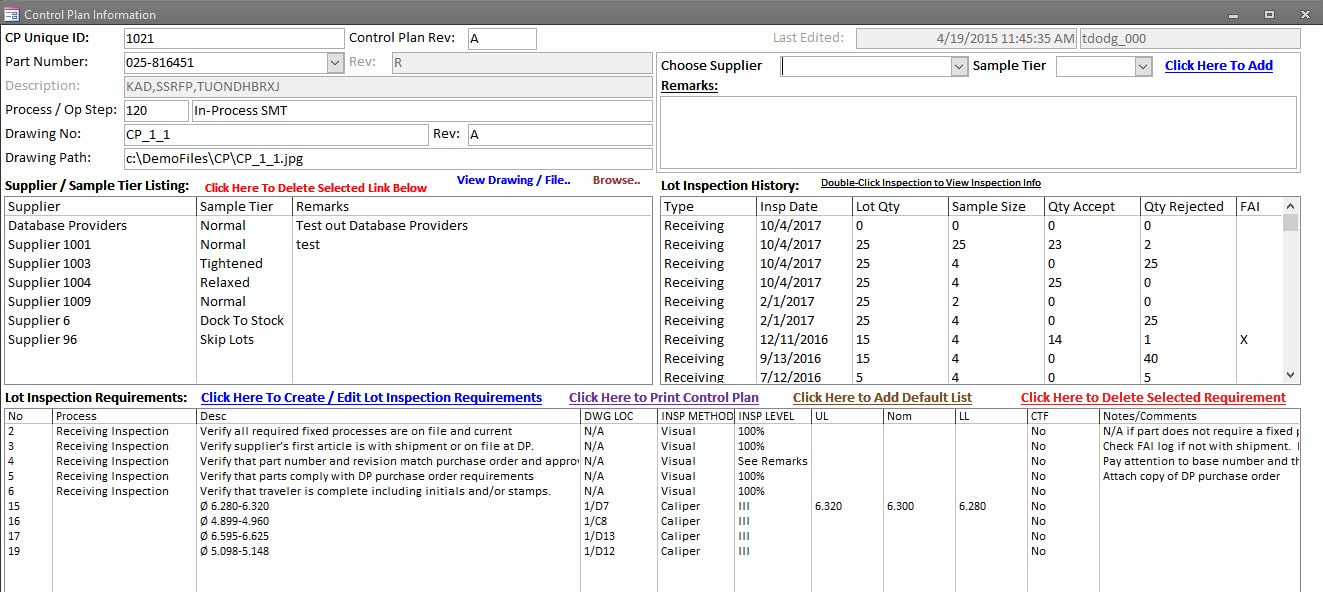

| Control Plan Definition

Control Plans are based on a specific Part Number and Part Revision. Additional fields such as Operation Step and Step No provide the Ability to Define Inspection Requirements for Specific Steps in a Manufacturing Router. A File can be Linked to the Control Plan. The file linked can be a Microsoft Word, Excel, Power Point, PDF or any other type of file. The typical use is a Drawing file. If the Control Plan is for a Receiving Inspection process, the list of Suppliers can be identified as well as the Inspection Method for Each Supplier. Inspection Method choices are 100% Inspection, Dock-To-Stock, Skip Lots and AQL Sampling Plans QL 0.5, 1.0, 1.5, c=0. For a Consistent approach to Inspections, Inspection Details can be Defined, that identifies What is to be Inspected, How it is to be Inspected and the Pass / Fail Criteria. |

|

| Inspection Requirements

Example of the Consistent approach to Inspections. Inspection Details define What is to be Inspected, How it is to be Inspected and the Pass / Fail Criteria. |

|

| Control Plans In-Use – Inspection Resuts

If a Control Plan exists for a Receiving Inspection process, the Control Plan Definition is copied into the Receiving Inspection record. The Receiver / Inspector is notified of the Inspection Method through the combination of the Part Number, Revision Level and Supplier defined in the Control Plan. In the event the Inspection Method is an AQL Sampling Plan, the Number of Pieces to be inspected is provided based on the Lot Size of the Quantity Recieved. The Inspector must complete all sections of the Inspection Report. In the case when a Measurement is required, the Inspector is provided an entry screen to enter each measurement of each unit inspected. Based on the Inspection results, the Inspector will either Accept or Reject the Lot. If the Lot is Rejected, a Nonconforming record is Automatically created, and the Defects are Itemized in the Inspection Record for Review and Dispositioning. In Process Inspection points follow the same process. |

|

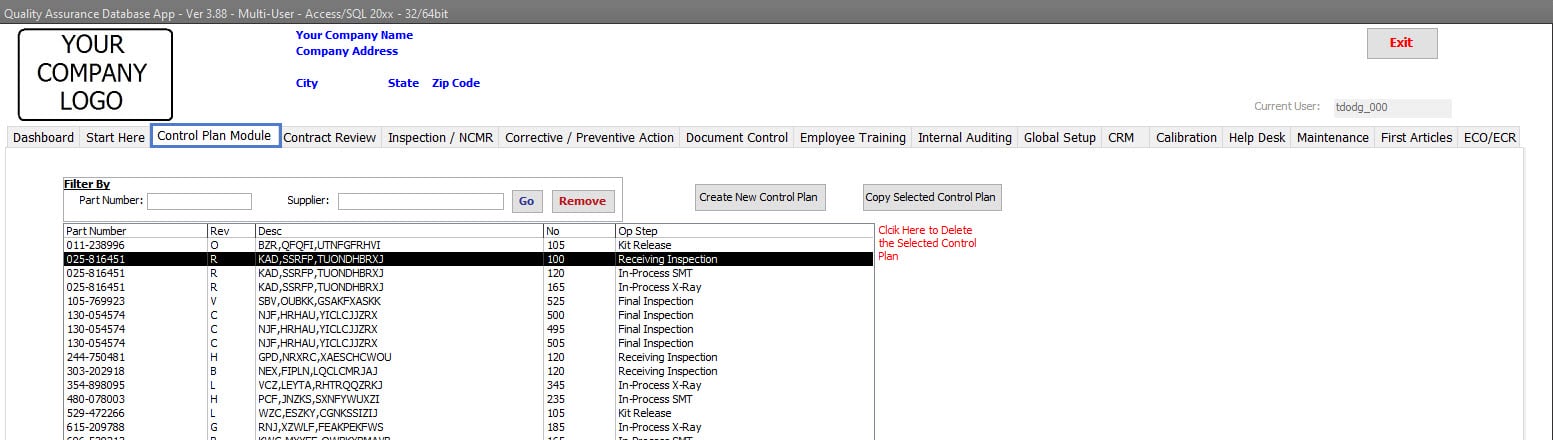

Control Plan View

Control Plans can be Searched using the Various Filters available.

Single-Click operation to View Existing Control Plan Details and to Start a New Control Plan.

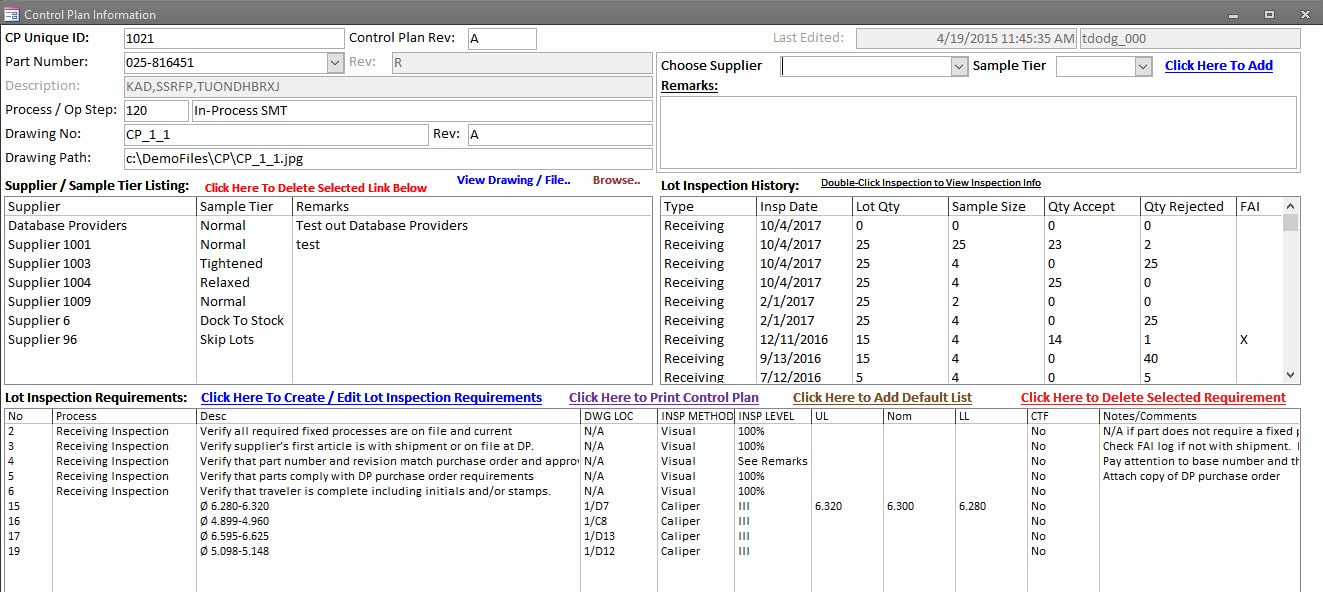

Control Plan Definition

Control Plans are based on a specific Part Number and Part Revision. Additional fields such as Operation Step and Step No provide the Ability to Define Inspection Requirements for Specific Steps in a Manufacturing Router.

A File can be Linked to the Control Plan. The file linked can be a Microsoft Word, Excel, Power Point, PDF or any other type of file. The typical use is a Drawing file.

If the Control Plan is for a Receiving Inspection process, the list of Suppliers can be identified as well as the Inspection Method for Each Supplier. Inspection Method choices are 100% Inspection, Dock-To-Stock, Skip Lots and AQL Sampling Plans QL 0.5, 1.0, 1.5, c=0.

For a Consistent approach to Inspections, Inspection Details can be Defined, that identifies What is to be Inspected, How it is to be Inspected and the Pass / Fail Criteria.

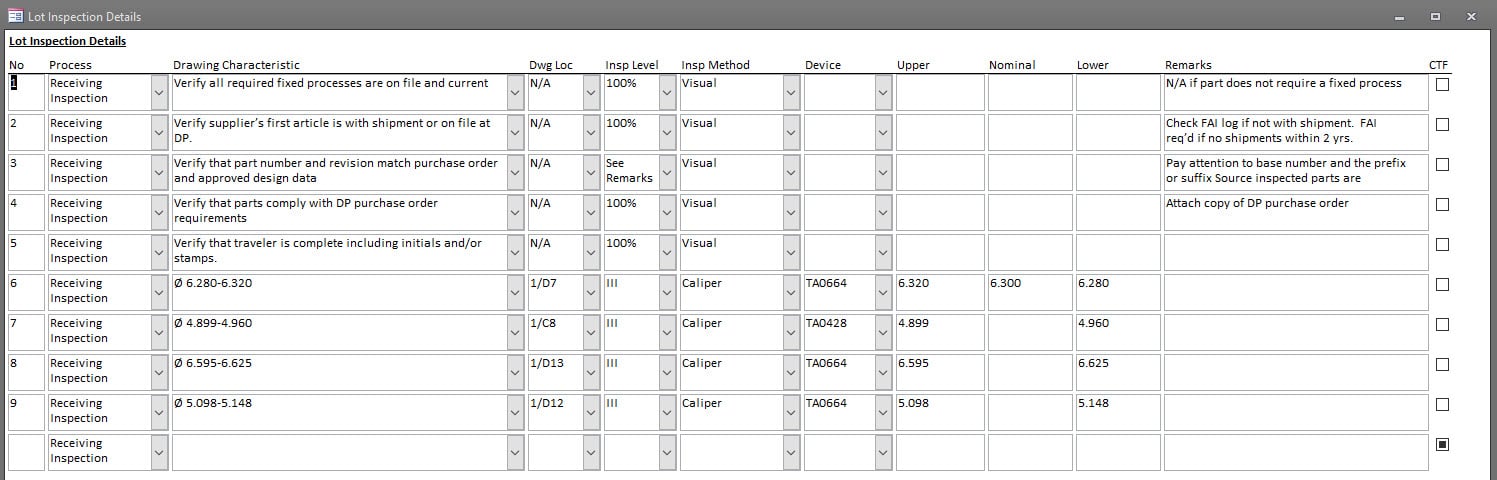

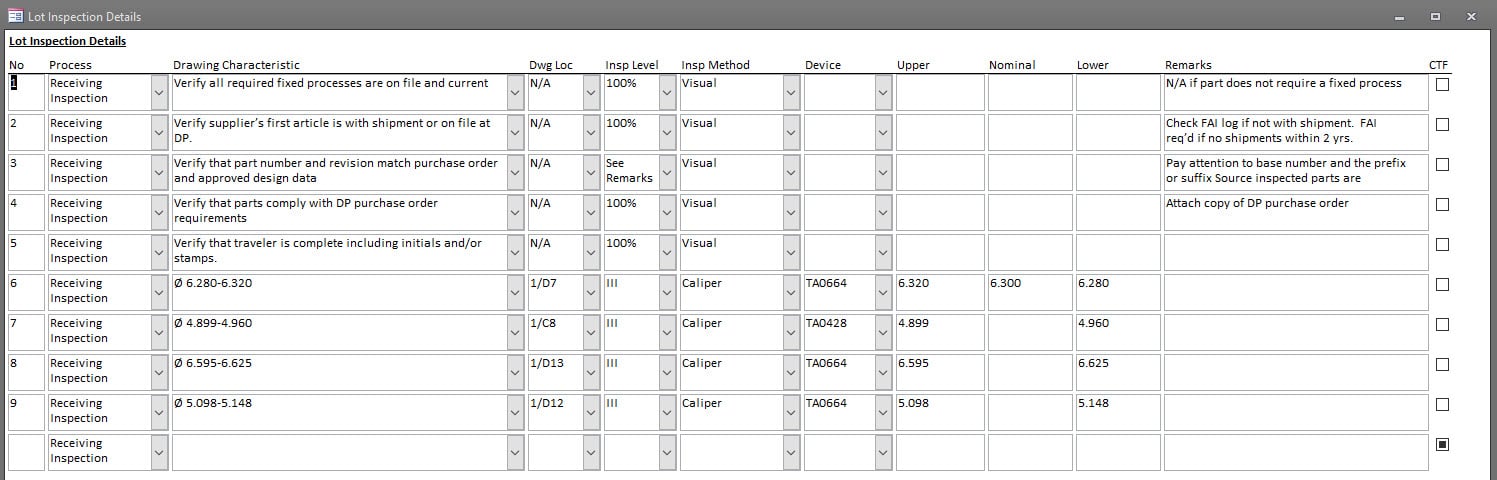

Inspection Requirements

Example of the Consistent approach to Inspections.

Inspection Details define What is to be Inspected, How it is to be Inspected and the Pass / Fail Criteria.

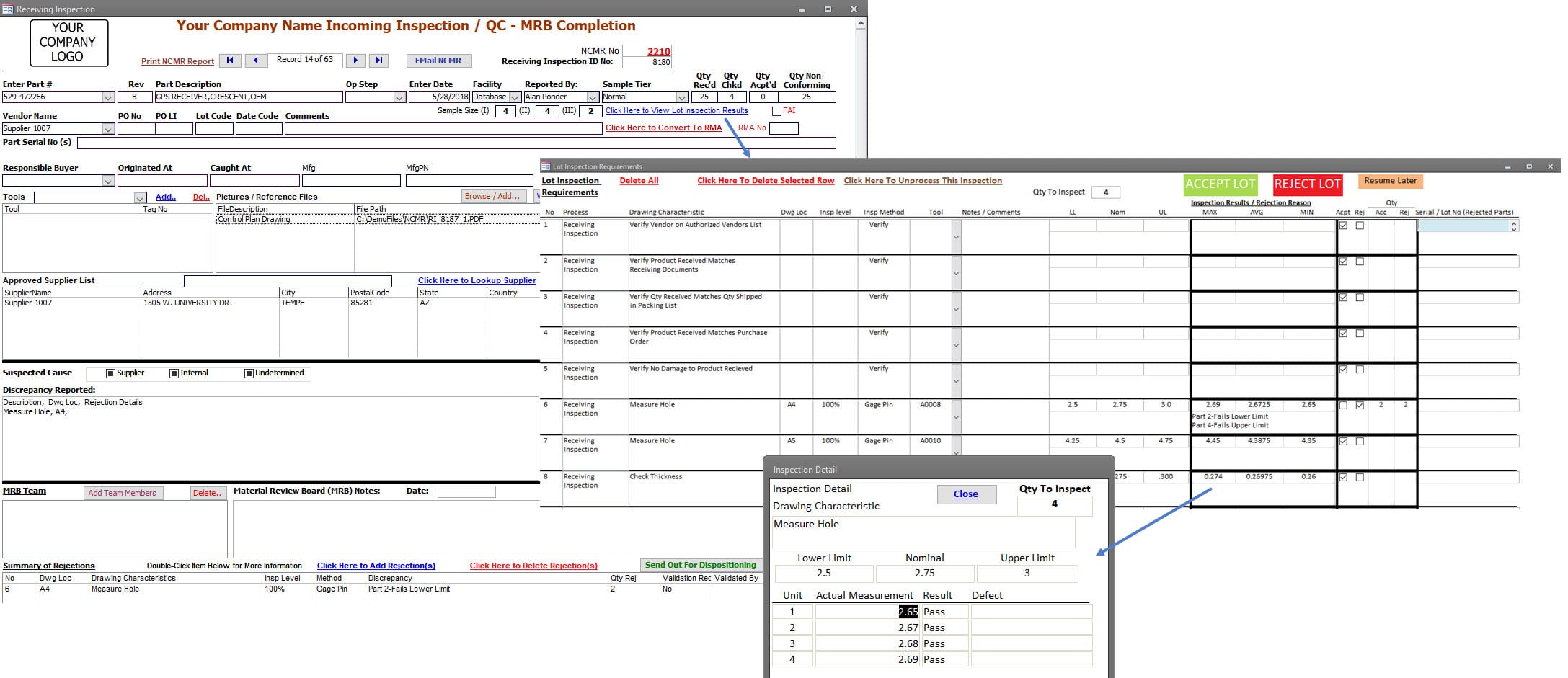

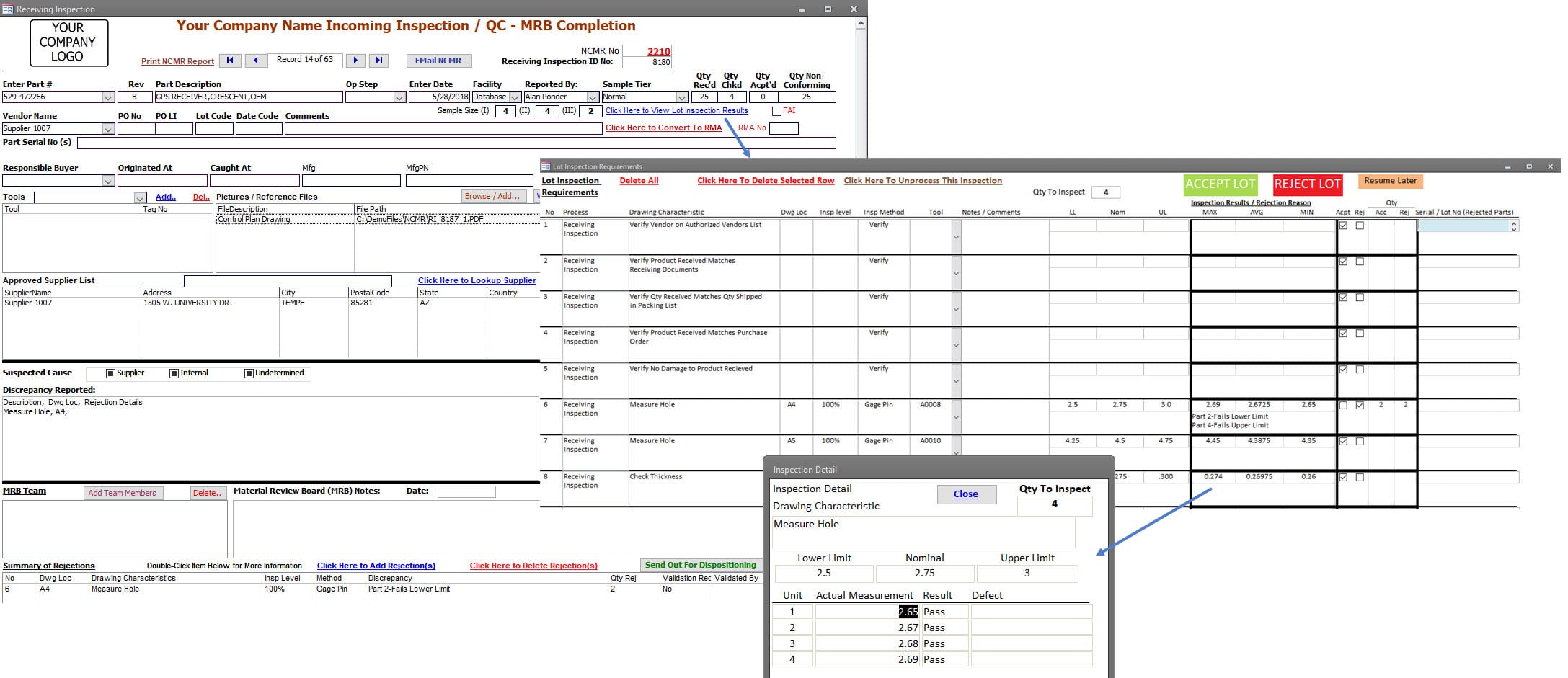

Control Plans In-Use – Inspection Resuts

If a Control Plan exists for a Receiving Inspection process, the Control Plan Definition is copied into the Receiving Inspection record. The Receiver / Inspector is notified of the Inspection Method through the combination of the Part Number, Revision Level and Supplier defined in the Control Plan. In the event the Inspection Method is an AQL Sampling Plan, the Number of Pieces to be inspected is provided based on the Lot Size of the Quantity Recieved.

The Inspector must complete all sections of the Inspection Report. In the case when a Measurement is required, the Inspector is provided an entry screen to enter each measurement of each unit inspected.

Based on the Inspection results, the Inspector will either Accept or Reject the Lot. If the Lot is Rejected, a Nonconforming record is Automatically created, and the Defects are Itemized in the Inspection Record for Review and Dispositioning.

In Process Inspection points follow the same process.

The use of Control Plans provides a Consistent Approach to How Product is Inspected and the Inspection History is helpful in Identifying Trends.

Connect with us to experience the difference

Don’t wait any longer! We’re here to guide you through the process and help you leverage this essential tool to enhance your quality control efforts. Your path to improved efficiency starts with a simple conversation.