Inspection and Non-conforming Material Software

Enhance Quality Control and Streamline ComplianceEffortlessly record, track, and manage inspections and non-conforming materials with our software. Experience seamless discrepancy documentation, disposition assignments, and closure of nonconformities, all crucial for ISO 9001 and AS 9100 compliance.

Inspection and Non-conforming Material Software Core Features

Get a glimpse of the key components of our Inspection and Non-conforming Material Software.

- Setup

- Inspections

- Non-Conformances

- Inspection Audit

- Non-Conformance Audit

- RMA

- RMA Non-Conformances

- Defects

- Navigation and Automation

Personalized setup to help you take control of your quality management. Add your company details and create an environment that reflects your business operations.

- Customizable system setup for a consistent branding.

- Comprehensive list management of employees, inspectors, parts, customers, and suppliers to streamline operations.

- Efficient email functionality setup for quick communication and task management.

| Book A Demo | More Details |

Our software is designed to elevate your inspection process. It is able to handle limitless inspections and allows you to capture detailed data for each inspection, thus ensuring comprehensive and transparent documentation.

- Conduct an unlimited number of inspections for meticulous quality assurance.

- Records data using an extensive range of fields, capturing all vital information including Part Number, Revision Level, Supplier, Inspection Date, Purchase Order No, and quantities received, inspected, accepted, and rejected.

- Offers additional fields for further granularity, such as Serial Numbers, Lot Number, Date Code, Buyer, Manufacturer, Manufacturer Part Number, Router Operation Step Number, and Inspection Method.

- Allows unlimited files to be linked to each inspection record, including certificates of conformance, test results, and packing lists.

| Book A Demo | More Details |

Non-Conformances Tracking

Handle discrepancies right from the receiving stage. Track and document non-conforming materials or products, assign dispositions, facilitate follow-up activities, and ensure your compliance with ISO 9001 and AS 9100.

- Comprehensive documentation of all discrepancies identified during receiving inspection.

- Efficient assignment of dispositions for each discrepancy, ensuring appropriate corrective actions.

- Identify each defect using defect codes and enable linking of files such as Drawings, Specifications, Pictures of Discrepancies, Work Instructions, etc to each non-conformance.

- Facilitates tracking of follow-up activities, approvals, and closure of non-conformities.

- Send task email to the responsible party or group, including the nonconforming details, all linked files, and the nonconformance report as attachments.

| Book A Demo | More Details |

Gain complete visibility over your production process with our WIP and Final Inspection features. Record an unlimited number of inspections using standard and additional fields to maintain stringent quality controls.

- Supports unlimited Work-In-Process (WIP) and Final Inspections for comprehensive oversight.

- Standard fields for efficient record keeping, such as Part Number, Revision Level, Inspection Date, Work Order No, Received Quantity, and more.

- Additional fields available for enhanced tracking, such as Customer, Serial Numbers, Lot Number, System Number, Router Operation Step Number, and Inspection Method.

| Book A Demo | More Details |

Optimize the handling of non-conformities during WIP or final inspections and transform challenges into improvement opportunities.

- Comprehensive documentation of discrepancies identified during WIP or Final Inspections.

- Assign multiple dispositions per discrepancy for optimal corrective action.

- Enables linking of files to non-conformances for complete record keeping.

| Book A Demo | More Details |

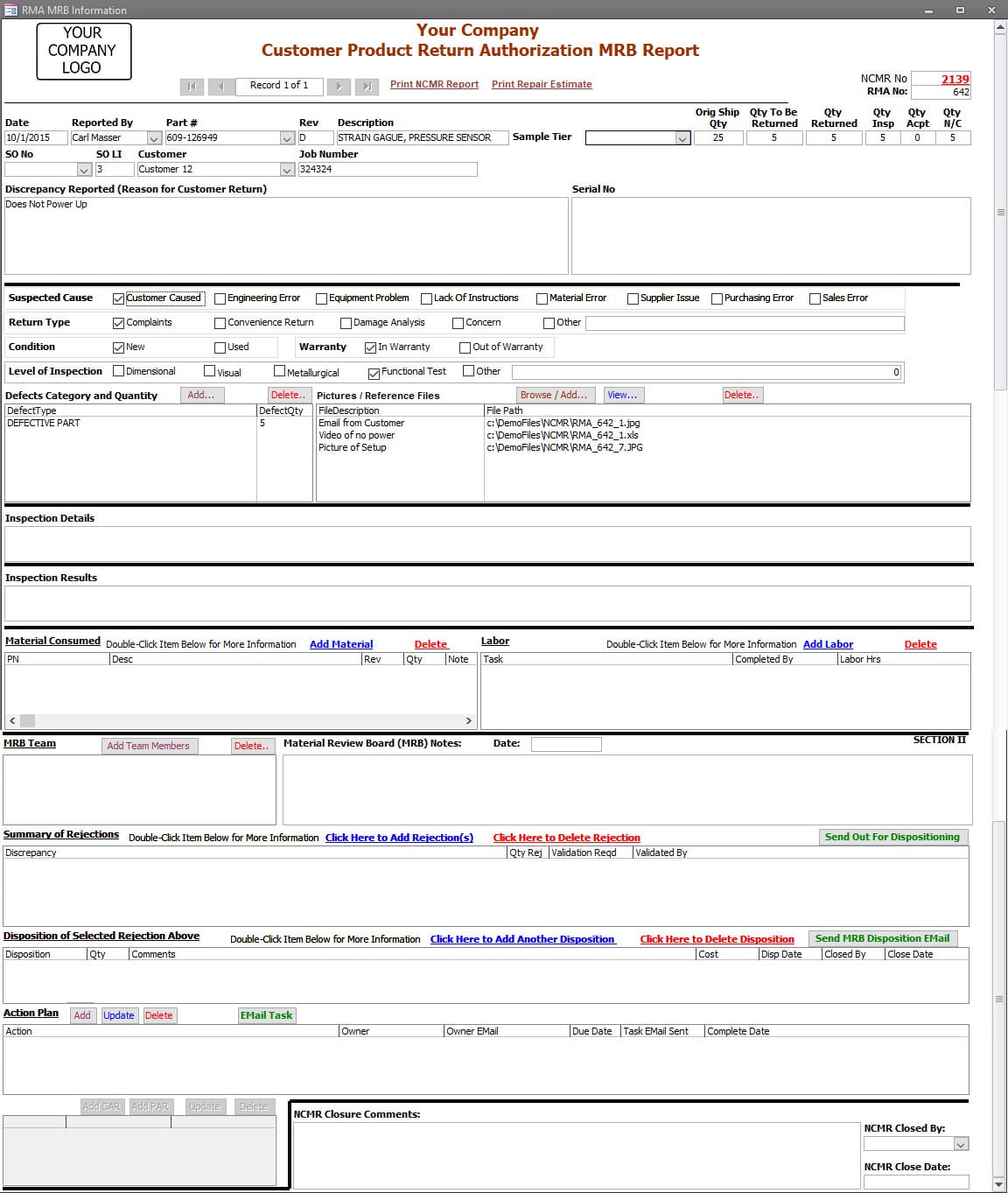

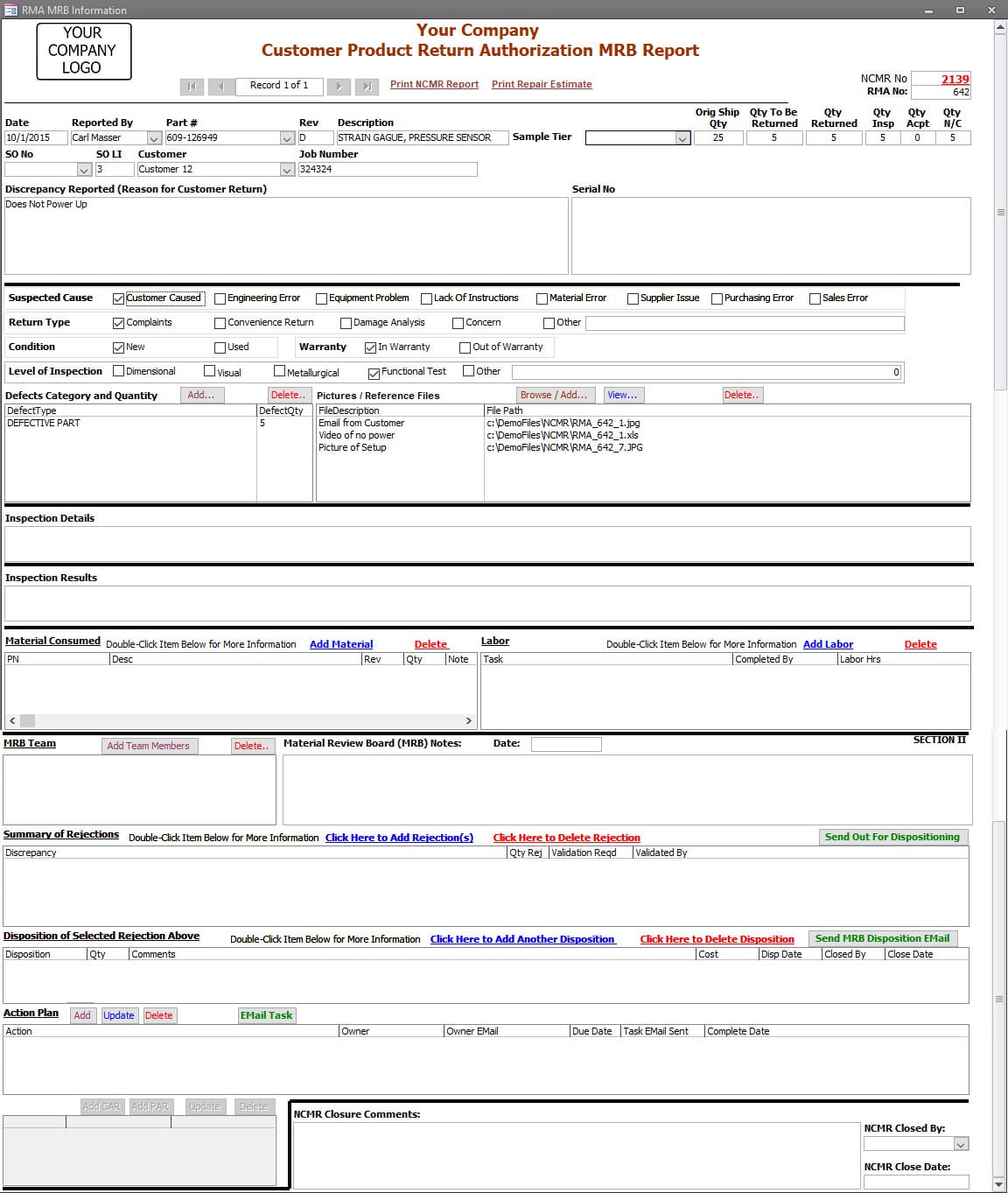

Maximize customer satisfaction by efficiently handling returns and learning from customer feedback. Record an unlimited number of customer returns and detail every aspect of the return to ensure customer satisfaction and compliance.

- Unlimited recording of customer returns for comprehensive management.

- Standard fields capture crucial information such as Part Number, Revision Level, Customer, Inspector, RMA Date, Returned Quantity, and more.

- Additional fields available for deeper insights, such as Serial Numbers, Inspection Details and Results, Inspection Method.

| Book A Demo | More Details |

Turn your customer feedback into a tool for improvement by efficiently managing non-conformities confirmed upon return. Identify suspected causes, document discrepancies, and create tasks to streamline the review and approval process.

- Detailed discrepancy identification and documentation upon customer return.

- Documents each discrepancy in detail, ensuring nothing gets overlooked.

- Facilitates the creation of tasks for efficient review, disposition, and approval process.

| Book A Demo | More Details |

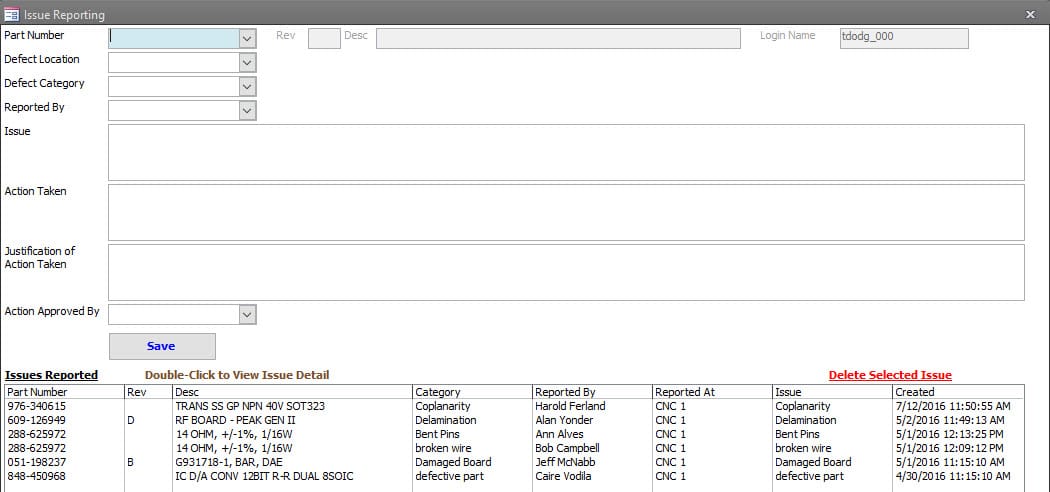

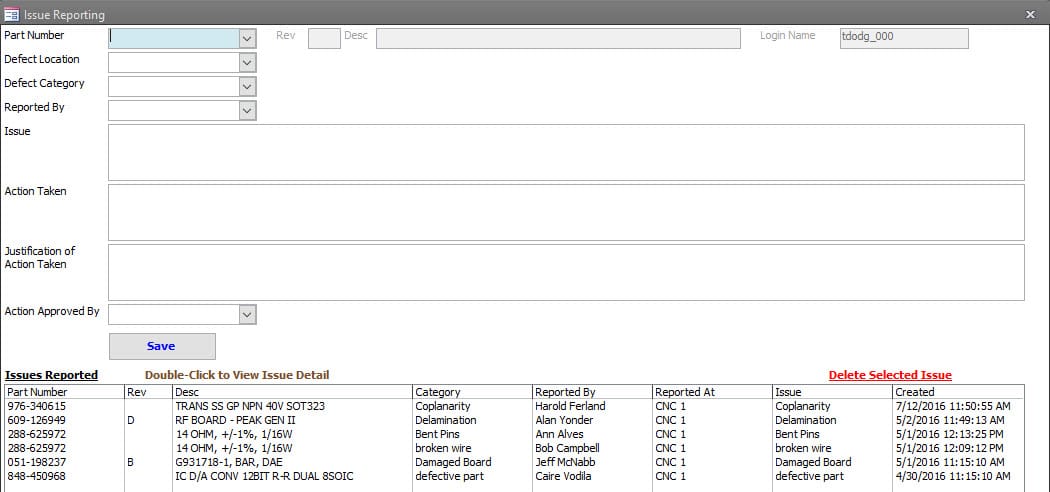

Turn defects into opportunities by tracking and managing them outside of the non-conformance process for a more streamlined work-in-process.

- Efficient recording and managing of defects during the work process.

- Tracks the removal and verification of defects for effective quality control.

| Book A Demo | More Details |

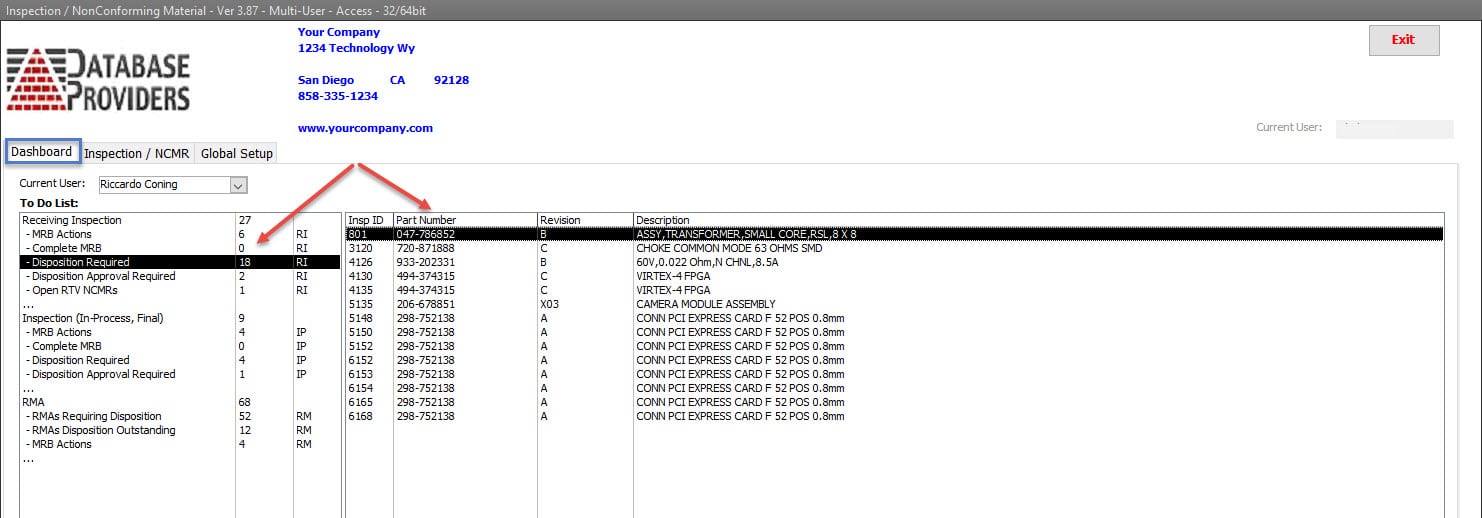

Navigate and manage your quality control effortlessly with our easy-to-use interface and automation features. Our software offers a user-friendly interface, instant summaries, and quick search options. Plus, automated tasks and emails streamline your quality management like never before.

- User-friendly interface for easy navigation through inspections and non-conformances.

- Quick access to open tasks and inspections for optimal productivity.

- Instant summaries of open inspections, dispositions required, and dispositions needing approvals.

- Automated data synchronization with most ERP systems.

- Scheduled emails for all open non-conformances and tasks.

| Book A Demo | More Details |

Why Choose Us?

Automation

Experience efficiency like never before with our advanced automation features. Improve productivity, streamline processes, and reduce human error to focus your resources on strategic quality improvements.

Seamless ERP/MRP Integration

Experience the power of synchronization. Our software harmonizes with your existing ERP/MRP and Business Systems to streamline your operations, enhance tracking, and provide actionable insights.

Open-Source Flexibility

Unmatched Customer Service and Support

Competitive Pricing & Flexible System Requirements

Unlock operational excellence with our advanced Inspection and Non-Conforming Material Software. Streamline inspections, and redefine excellence.

Ready to Get Started?

Achieve operational perfection by taking control of your inspection management. Unlock the potential of strategic inspections with our Inspection and Non-Conforming Material Software to help you grow your business with custom inspection and control.

Ready to experience the game-changing potential of Database Providers’ software? Contact us now to schedule a personalized demo for your inspection and non-conformance needs.

|

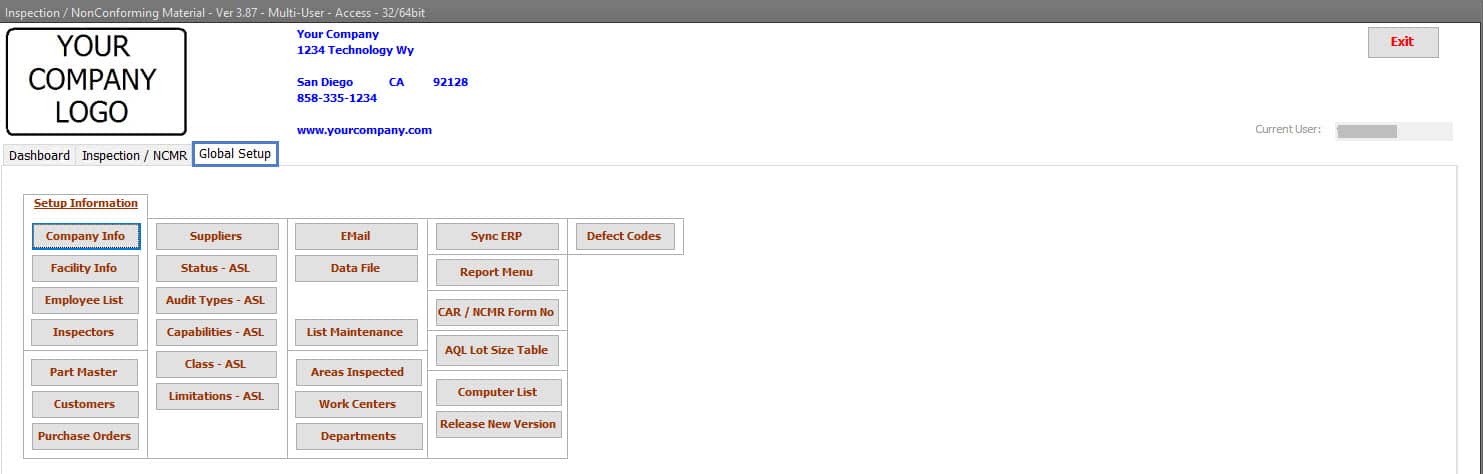

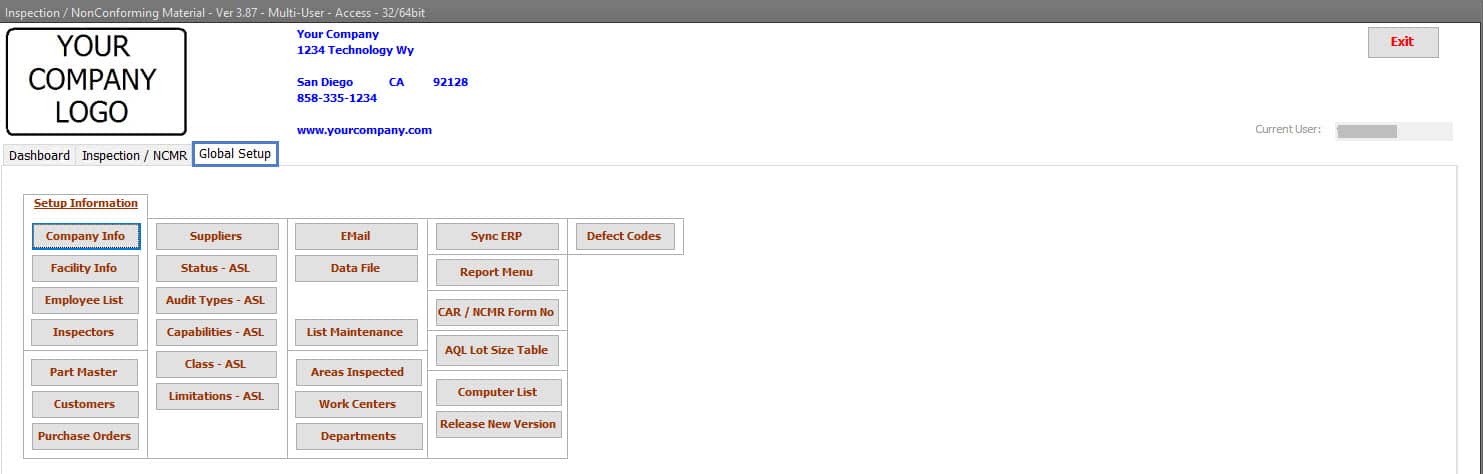

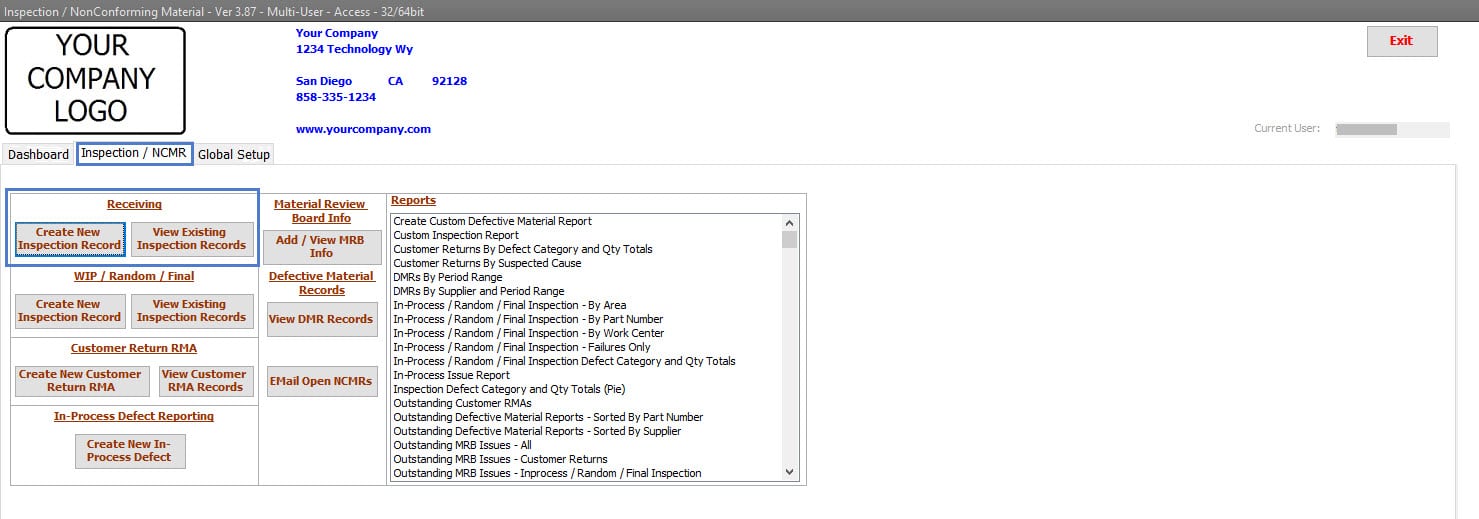

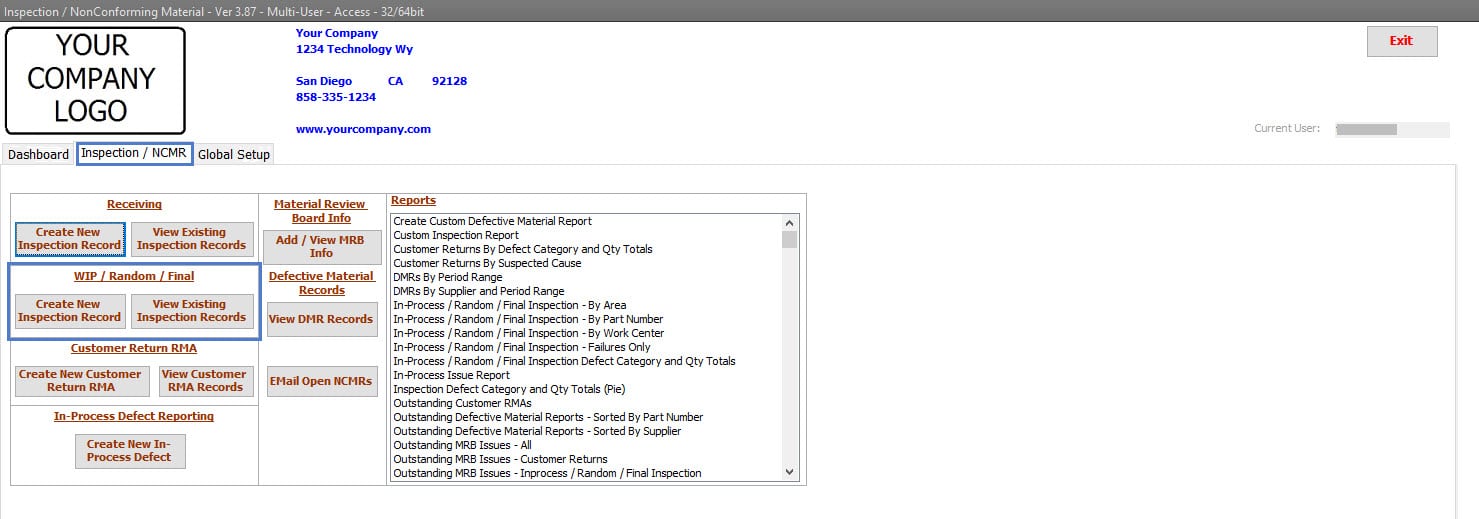

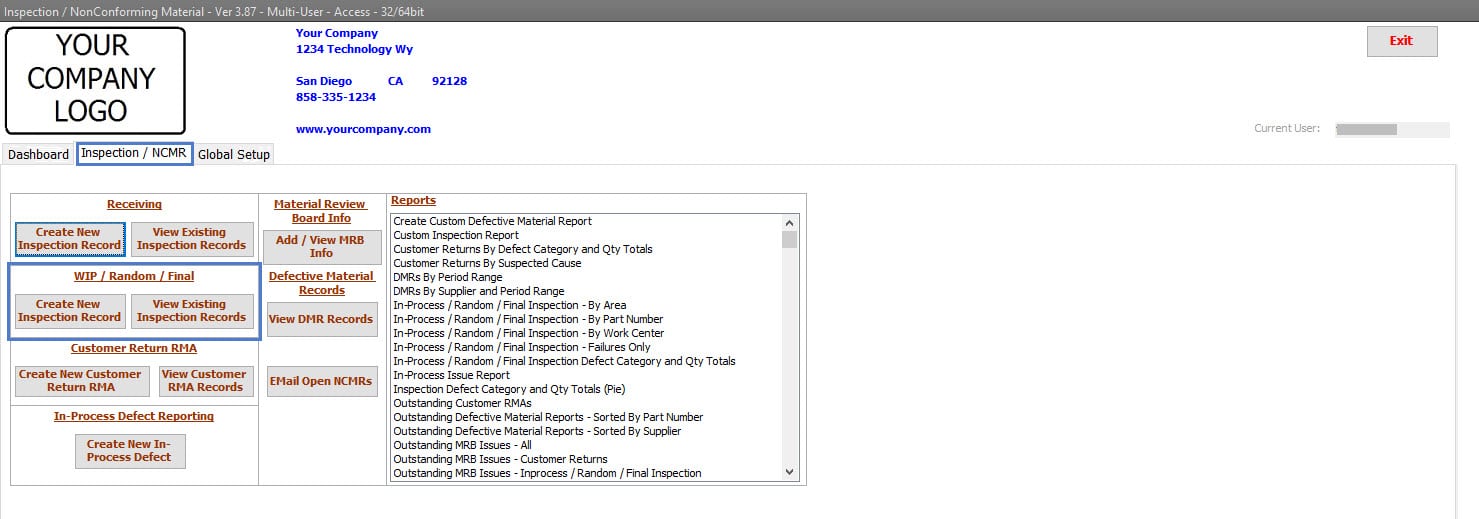

Global Setup Easily manage all of the global settings and lists used throughout the database.

|

|

Global Setup

Easily manage all of the global settings and lists used throughout the database.

- Your Company Info.

- Facility List.

- Employee List.

- Part Master.

- Customers.

- Suppliers.

- Work Orders.

- Purchase Orders.

- Work Centers, Departments, and Area Inspected.

- Defect List – Global, Receiving, Work In Process, Customer RMA, and Final Inspection.

- Sampling Plans.

- Email Server Settings.

- ERP Sync Settings.

| Receiving Inspection Section

The Receiving Inspection section can record all receiving inspections performed, or only those with non-conforming material are identified. |

|

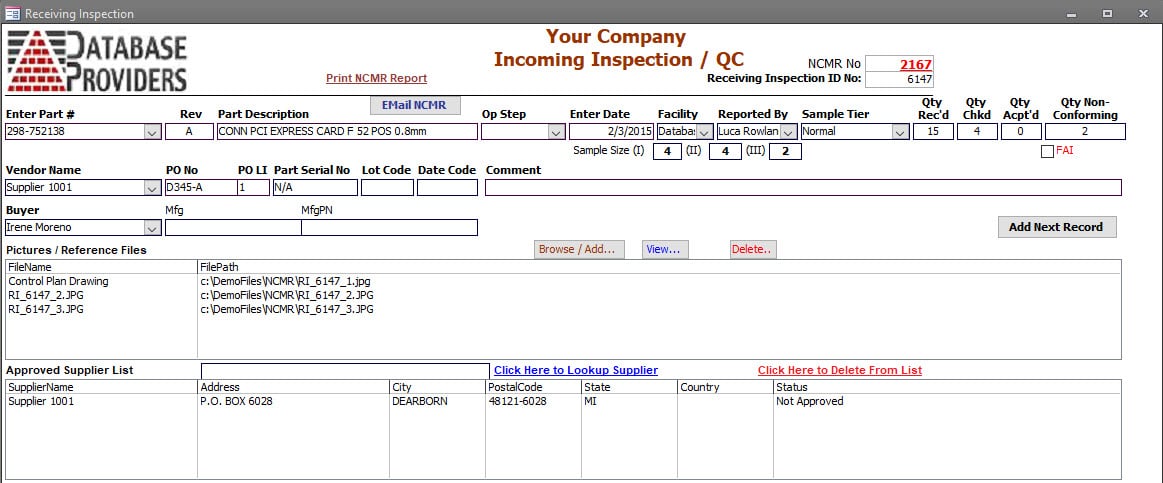

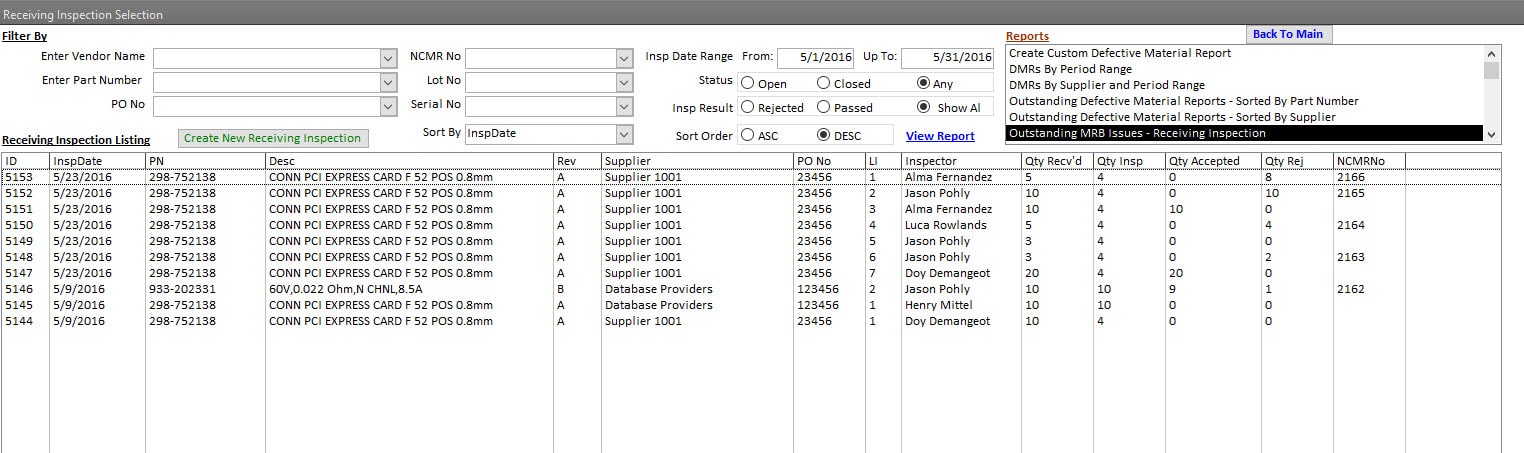

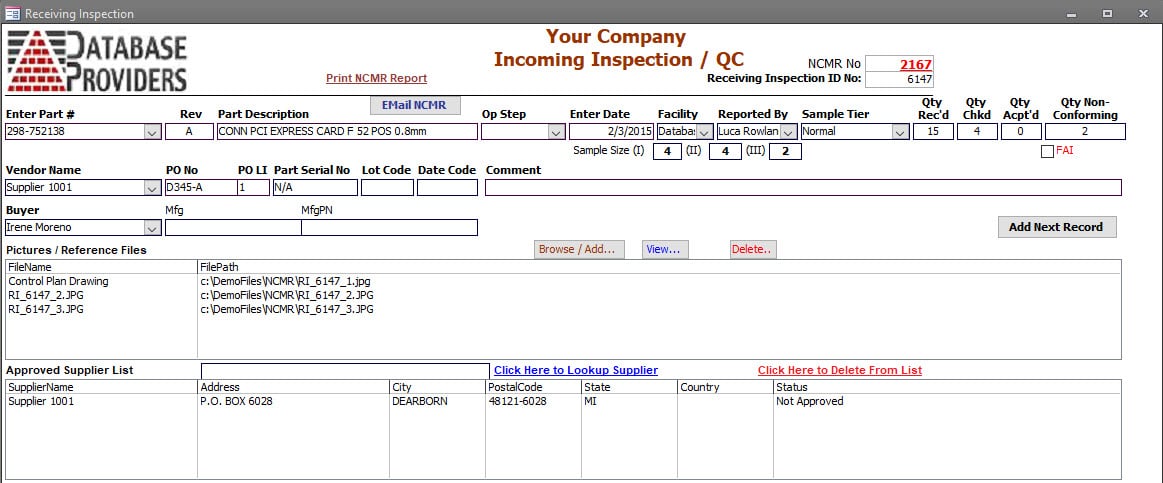

| Receiving Inspections – Search and View

Receiving Inspection records can be searched using various fields and any combination of the fields. All reports revolving around Receiving Inspection data can also be Viewed from this area. Quickly view a Receiving Inspection record with a double click on the Inspection item, and the full details of the Receiving Inspection record are Displayed. |

|

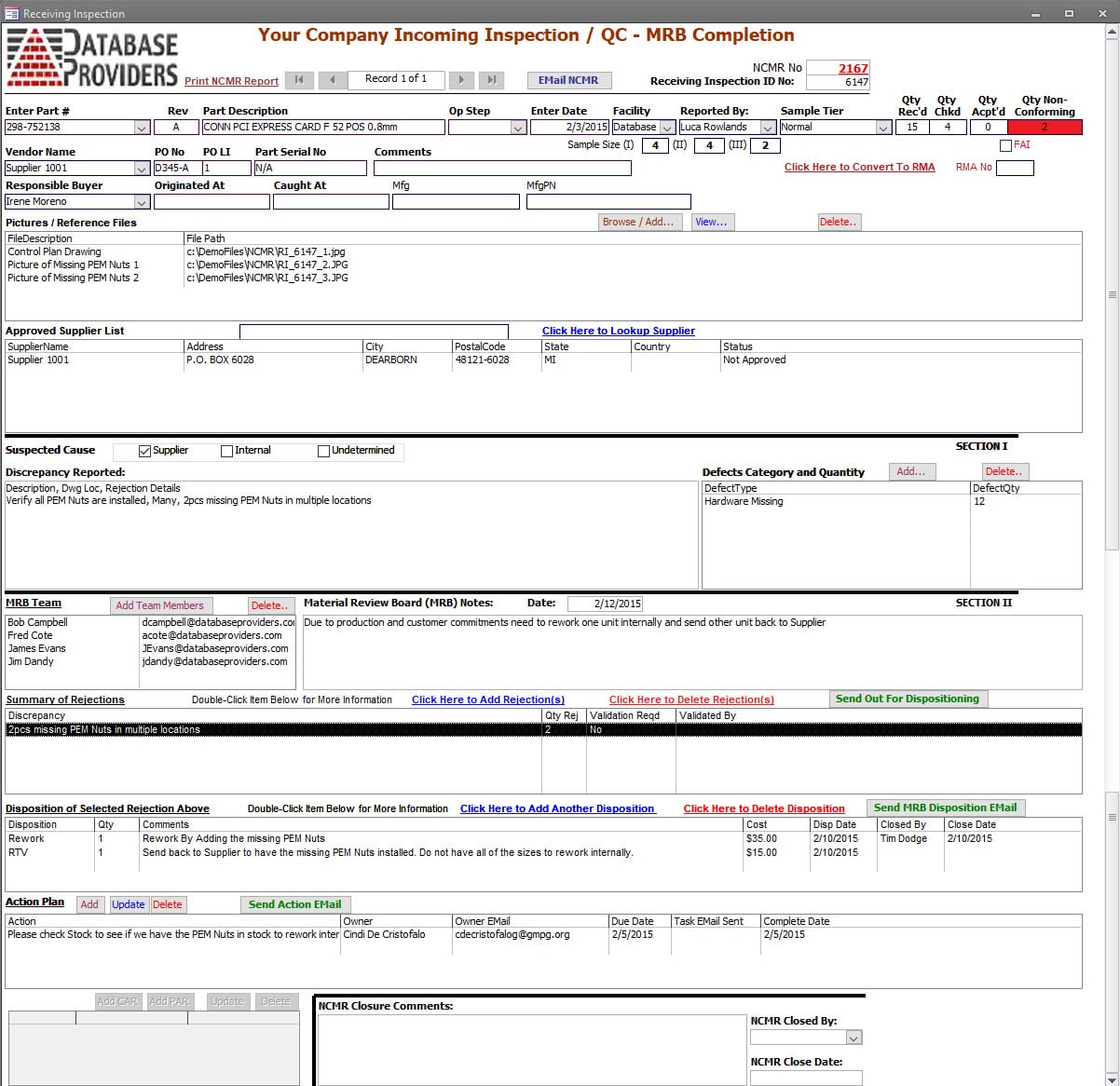

| Receiving Inspection Information

For Receiving Inspection, many standard fields are available. The organization decides what information has value and is to be populated. Common Fields exist, such as: Inspection Date, Part Number, Part Description, and Part Revision Level, Supplier, Purchase Order No, and Line Item, Quantity Received, Inspected, Accepted, and Rejected. In addition, other fields, such as: Lot Code, Date Code, Serial Numbers, Buyer, Part Manufacturer, Manufacturers Part Number, and Inspection Method options such as 100% Inspection, Dock-To-Stock, Skip Lots, and AQL 0.5, 1.0, 1.5 C=0 sampling plans, is available depending on the organization’s requirements. Files can be linked to each inspection. A common practice is to add a Packing List, Certificate of Conformance, Test Results, Drawings, and Pictures of non-conformances. Once linked, files can be viewed at any time in the future. The current approval status of the Supplier/Vendor is added to the Approved Supplier List—section of the Inspection record. NOTE: If organizations want to reduce data entry, this Inspection and Non-Conforming software can maintain Purchase Order information through a direct link to many ERP systems or an automated sync process of Purchase Order information—Call Database Providers to learn more about this feature. When this direct link or sync feature is used, many fields are pre-populated based on the PO No and Line Item entered by the receiver. In most cases, the Part Number, Part Revision Level, Vendor / Supplier Name, PO No, and PO Line Item fields are all populated from the Purchase Order information. In addition to those fields, numerous other fields, such as Lot Code, Date Code, Serial Numbers, etc., can be populated depending on the amount of data the Purchase Order contains on the ERP side. |

|

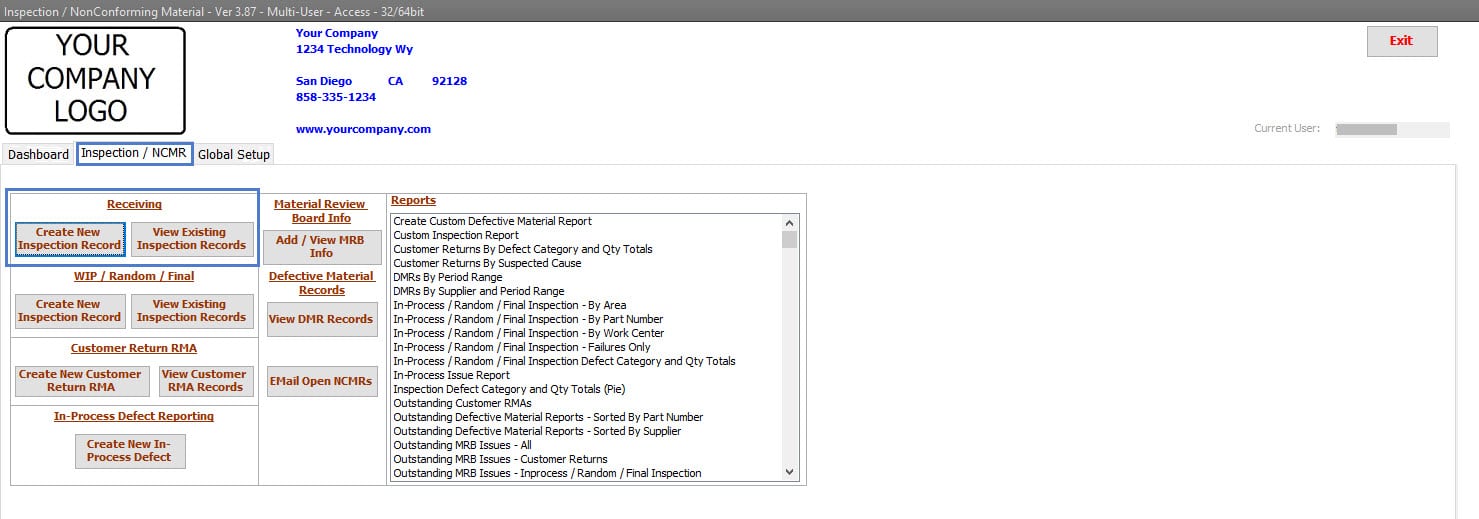

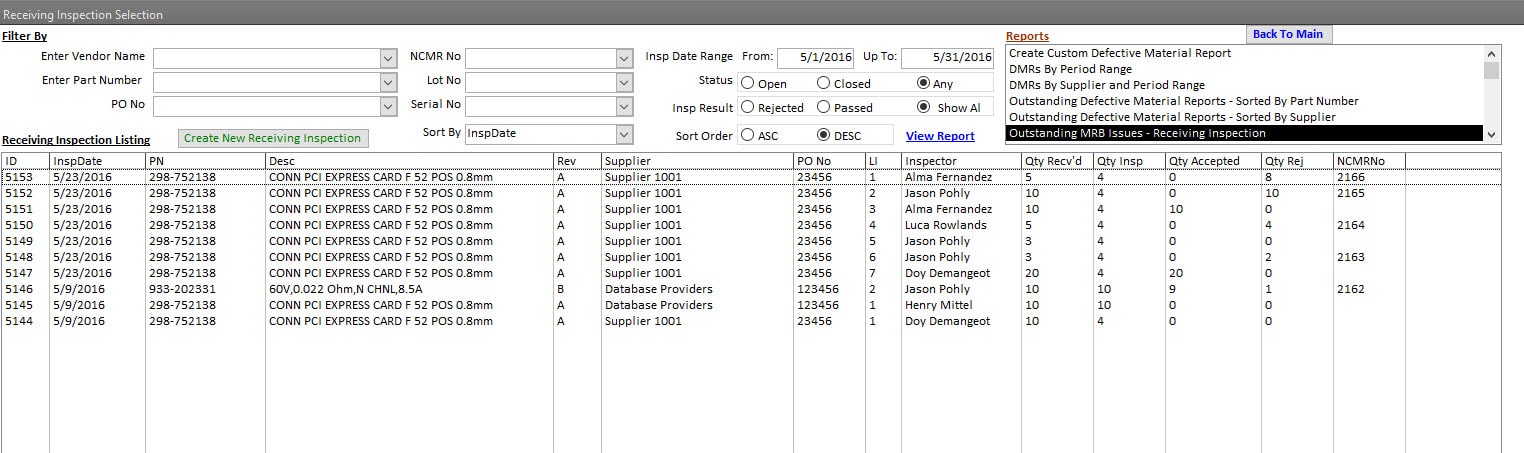

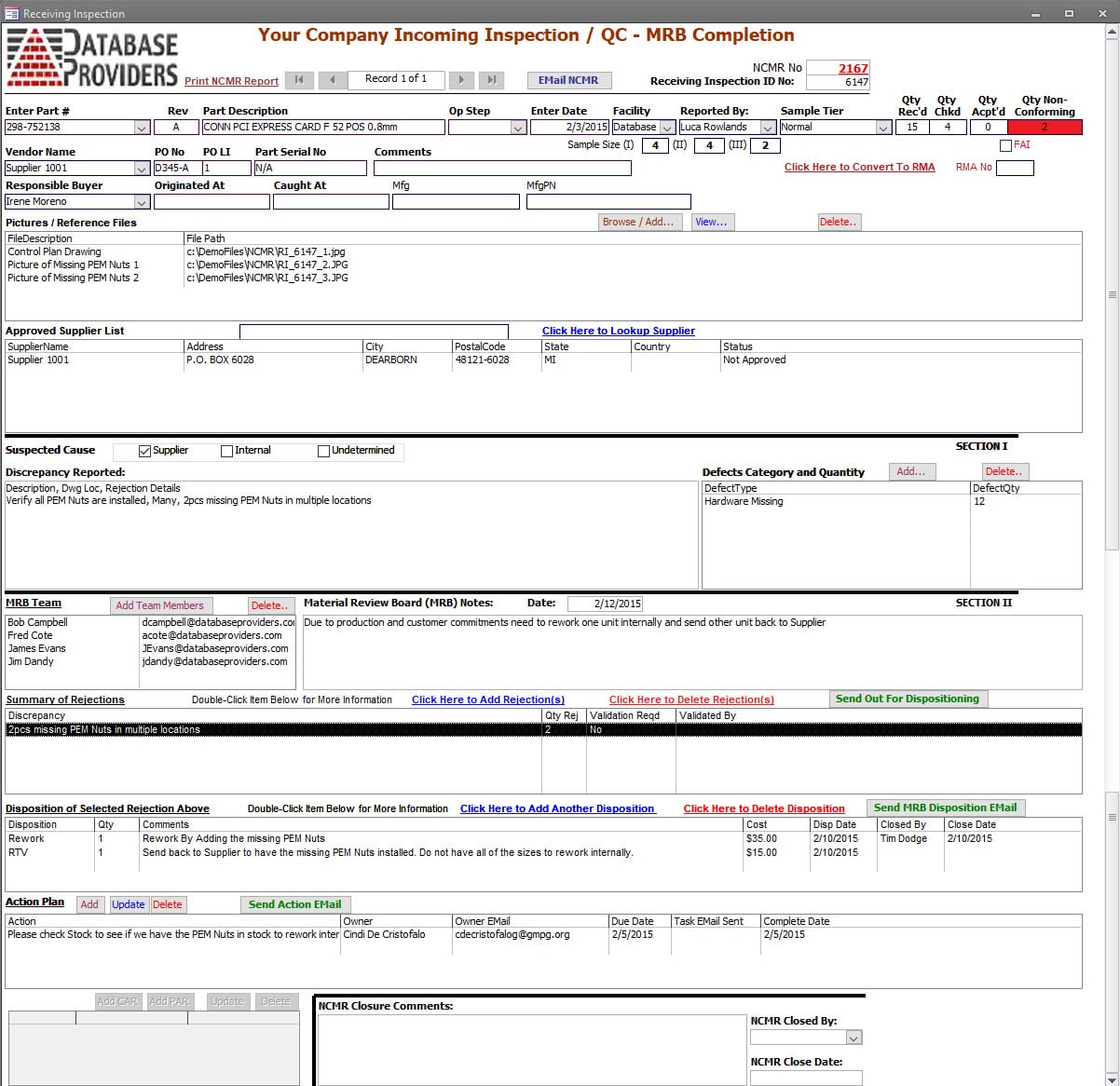

Receiving Inspection Section

The Receiving Inspection section can record all receiving inspections performed, or only those with non-conforming material are identified.

Receiving Inspections – Search and View

Receiving Inspection records can be searched using various fields and any combination of the fields.

All reports revolving around Receiving Inspection data can also be Viewed from this area.

Quickly view a Receiving Inspection record with a double click on the Inspection item, and the full details of the Receiving Inspection record are Displayed.

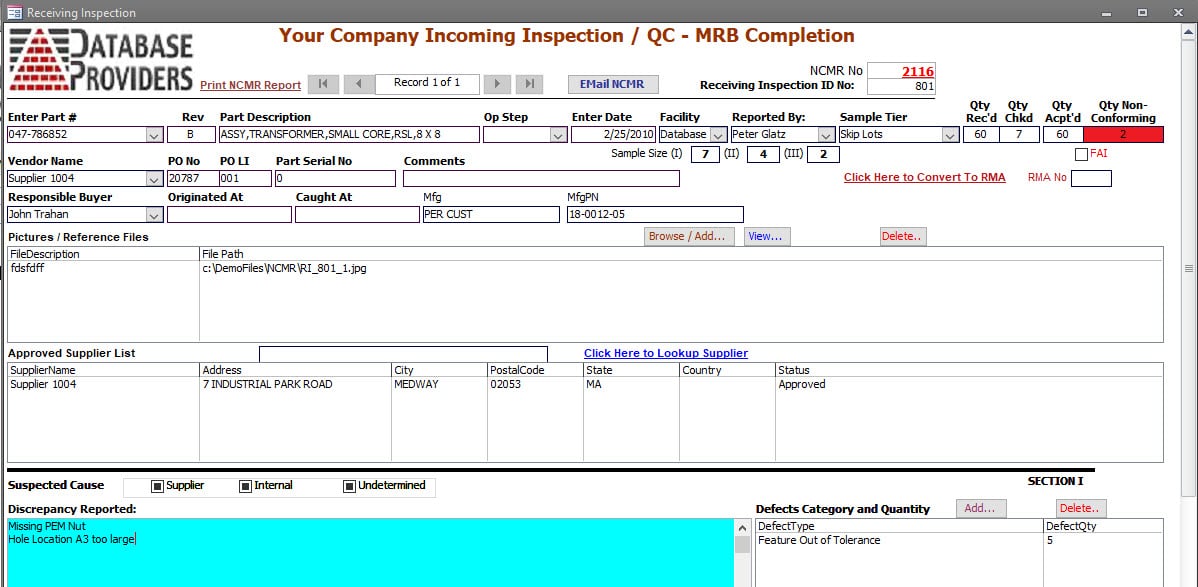

Receiving Inspection Information

For Receiving Inspection, many standard fields are available. The organization decides what information has value and is to be populated.

Common Fields exist, such as:

Inspection Date, Part Number, Part Description, and Part Revision Level, Supplier, Purchase Order No, and Line Item, Quantity Received, Inspected, Accepted, and Rejected.

In addition, other fields, such as

Lot Code, Date Code, Serial Numbers, Buyer, Part Manufacturer, Manufacturers Part Number, and Inspection Method options such as 100% Inspection, Dock-To-Stock, Skip Lots, and AQL 0.5, 1.0, 1.5 C=0 sampling plans, is available depending on the organization’s requirements.

Files can be linked to each inspection. A common practice is to add a Packing List, Certificate of Conformance, Test Results, Drawings, and Pictures of non-conformances. Once linked, files can be viewed at any time in the future.

The current approval status of the Supplier/Vendor is added to the Approved Supplier List—section of the Inspection record.

NOTE: If organizations want to reduce data entry, this Inspection and Non-Conforming software can maintain Purchase Order information through a direct link to many ERP systems or an automated sync process of Purchase Order information—Call Database Providers to learn more about this feature.

When this direct link or sync feature is used, many fields are pre-populated based on the PO No and Line Item entered by the receiver. In most cases, the Part Number, Part Revision Level, Vendor / Supplier Name, PO No, and PO Line Item fields are all populated from the Purchase Order information. In addition to those fields, numerous other fields, such as Lot Code, Date Code, Serial Numbers, etc., can be populated depending on the amount of data the Purchase Order contains on the ERP side.

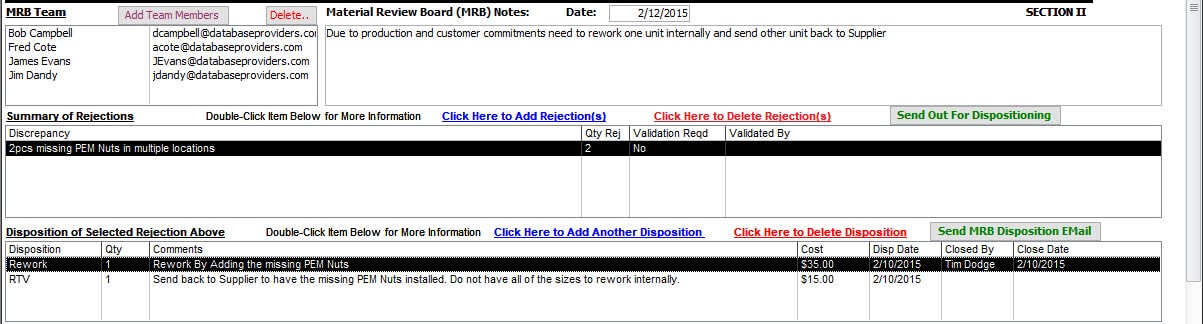

| Receiving Inspection – Nonconforming Product

For NonConforming Material, the discrepancy is identified. And a unique identifier is created for the Inspection record. The Defect Category and Quantity can be captured for Pareto Chart reporting purposes. The MRB Team can be identified. All rejections can be identified individually. Useful when more than one discrepancy is found within the inspected lot. Each rejection can have multiple dispositions, and those dispositions are identified. (E.g., some quantity can be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.) The one-click process to Generate and Send Emails asking for dispositioning and to those responsible for executing the disposition. Actions (or task items) can be entered and assigned to specific parties (individuals) throughout the process. Open Action items are visible in the dashboard. NOTE: If the Corrective Action module is also purchased, if a Corrective Action is warranted, the one-click process creates a corrective action and links to the inspection record. |

|

| NonConformance Identification

All Discrepancies found can be recorded in the inspection record. Each Discrepancy contains the Expected Condition and the Discrepancy. In addition, serial Numbers and Lot Numbers can be added to Each Discrepancy recorded. |

|

| NonConformance Dispositioning

Each Discrepancy can have Multiple Dispositions. Each Disposition entered shows the Expected Condition, Discrepancy, Disposition Quantity, and Disposition Date. The Disposition Cost is also available for those organizations tracking Cost of Quality (CoQ). The system captures Who Entered the Disposition and the ability to Approve the Disposition using an approval password process. When the Disposition is returned to Vendor, additional fields are available to record the Suppliers RMA Number, Buyer Info, Date Product Shipped to the Supplier, and Date the Product was Returned from the Supplier. |

|

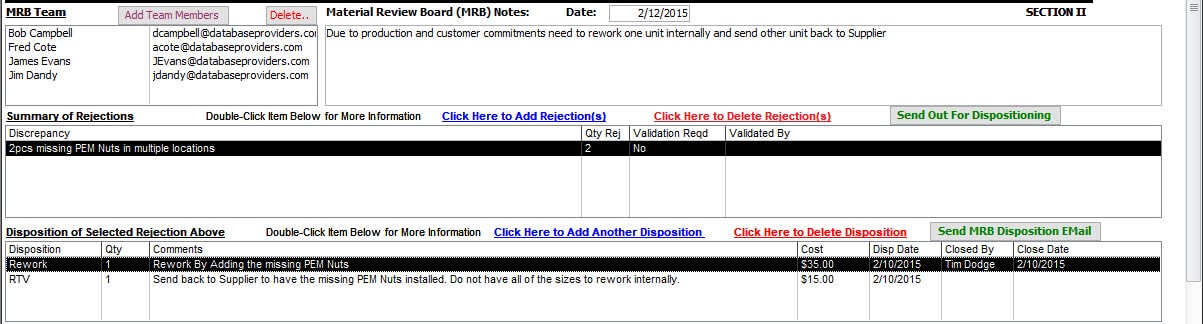

Receiving Inspection – Nonconforming Product

For NonConforming Material, the discrepancy is identified. And a unique identifier is created for the Inspection record.

Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings and pictures of non-conformances.

The Defect Category and Quantity can be captured for Pareto Chart reporting purposes.

The MRB Team can be identified.

All rejections can be identified individually. Useful when more than one discrepancy is found within the inspected lot. Each rejection can have multiple dispositions, and those dispositions are identified. (E.g., some quantity can be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.)

The one-click process to Generate and Send Emails asking for dispositioning and to those responsible for executing the disposition.

Actions (or task items) can be entered and assigned to specific parties (individuals) throughout the process. Open Action items are visible in the dashboard.

NOTE: If the Corrective Action module is also purchased, if a Corrective Action is warranted, the one-click process creates a corrective action and links to the inspection record.

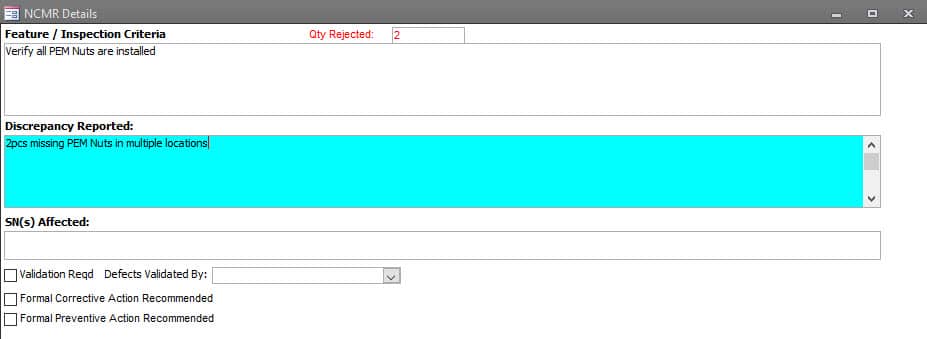

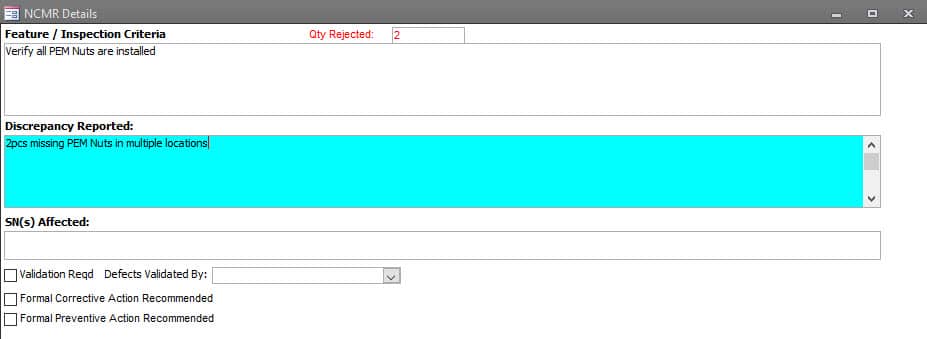

NonConformance Identification

All Discrepancies found can be recorded in the inspection record.

Each Discrepancy contains the Expected Condition and the Discrepancy.

In addition, serial Numbers and Lot Numbers can be added to Each Discrepancy recorded.

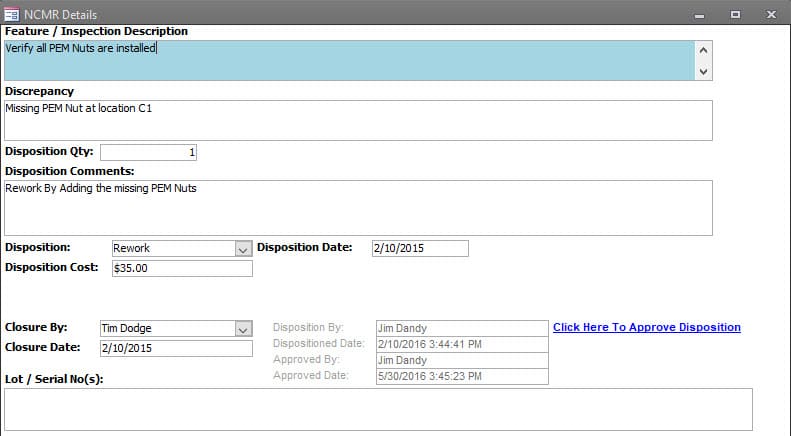

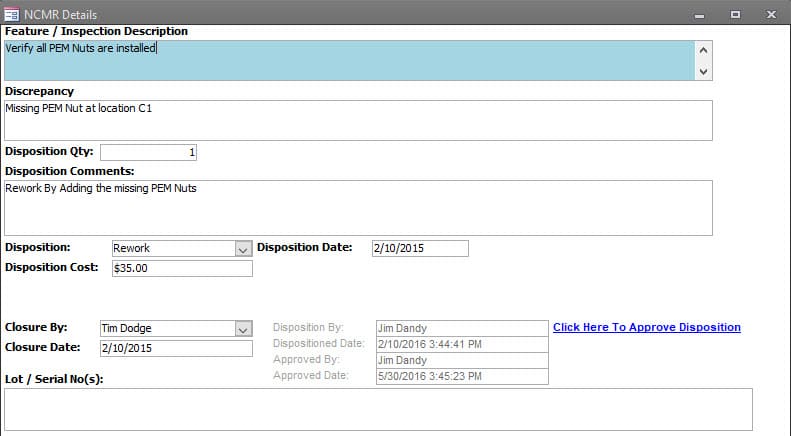

NonConformance Dispositioning

Each Discrepancy can have Multiple Dispositions.

Each Disposition entered shows the Expected Condition, Discrepancy, Disposition Quantity, and Disposition Date.

The Disposition Cost is also available for those organizations tracking Cost of Quality (CoQ).

The system captures Who Entered the Disposition and the ability to Approve the Disposition using an approval password process.

When the Disposition is returned to Vendor, additional fields are available to record the Suppliers RMA Number, Buyer Info, Date Product Shipped to the Supplier, and Date the Product was Returned from the Supplier.

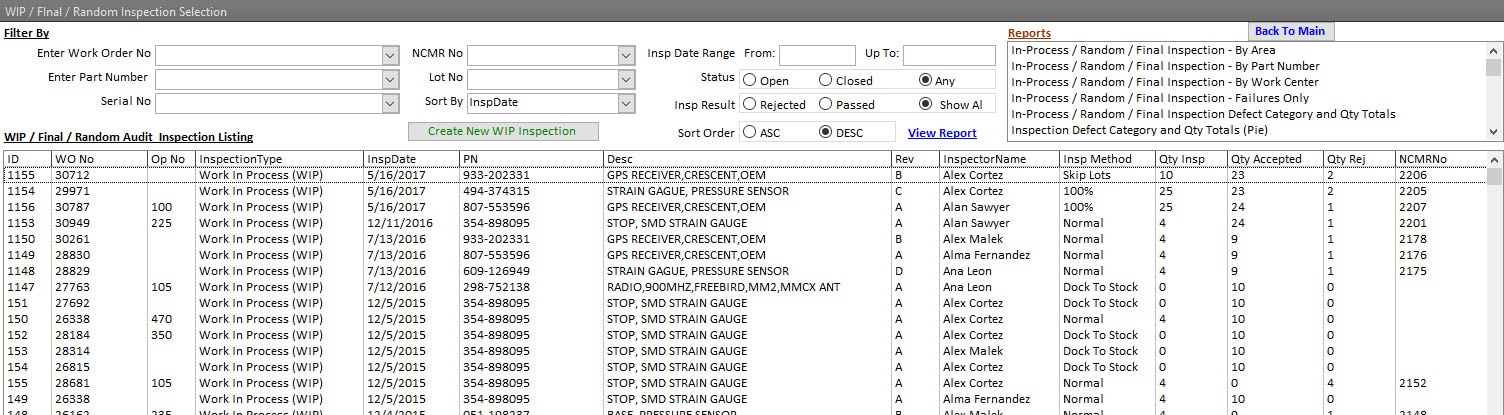

| Work In Process Inspection

This section can record all Work-In-Process (WIP), Final Inspections, and Random Audit Inspections performed or only those where nonconforming material is identified. |

|

| Work In Process (WIP) Inspection Search and View

Work-In-Process (WIP), Final Inspections, and Random Audit inspection records can be searched using various fields and any combination of the fields. All Reports revolving around Work-In-Process (WIP), Final Inspections, and Random Audit inspection records can be viewed with a double-click. |

|

| Work In Process (WIP) Inspection Information

Many standard fields are available for Work-In-Process (WIP) or Final Inspection entry. The organization should decide what information has value and should be populated. Standard fields that exist are: Inspection Date, Part Number, Part Description, Part Revision Level, Work Order Number, Lot Quantity, Quantity Inspected, Accepted, and Rejected. Other fields, such as: System Number, Customer, Work Center and Area Inspected, Serial Numbers, and Inspection Method options such as 100% Inspection, Skip Lots, and AQL 0.5, 1.0, 1.5 C=0 sampling plans are available depending on the organization’s inspection requirements. When the Calibration Management Software is purchased and integrated within this Inspection and Nonconforming Material software, the tools (measurement devices) used to perform the inspection can be linked to the inspection record. This is incredibly convenient if a measurement device’s “Condition as Found” is out of specification during its calibration process. Organizations know precisely the product inspected using the measurement device and can immediately determine the effect of the inspection result based on an out-of-specification condition. Files can be linked to each inspection. Options might include Test Results, Completed Inspection forms, or Drawings. Linked files can be viewed at any time in the future. NOTE: If organizations want to reduce data entry, this Inspection and Non-Conforming software can maintain Work Order information through a direct link to many ERP systems or an automated sync process of Work Order information—Call Database Providers to learn more about this feature. When this direct link or sync feature is used, many fields are pre-populated based on the Work Order Number entered by the inspector. In most cases, the Part Number, Revision Level, Description, and Work Order Quantity fields are all populated from the Work Order information. In addition to those fields, other fields, such as Area Inspected, Work Center, Lot Code, Date Code, Serial Numbers, and System Number, can be pre-populated depending on the amount of information available by the ERP system. |

|

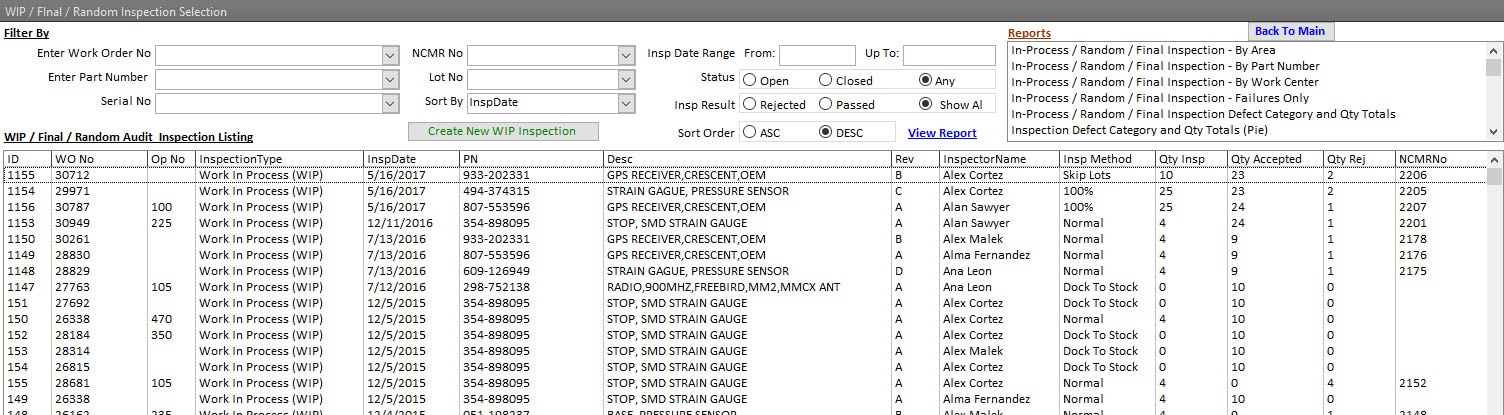

Work In Process Inspection

This section can record all Work-In-Process (WIP), Final Inspections, and Random Audit Inspections performed or only those where nonconforming material is identified.

Work In Process (WIP) Inspection Search and View

Work-In-Process (WIP), Final Inspections, and Random Audit inspection records can be searched using various fields and any combination of the fields.

All Reports revolving around Work-In-Process (WIP), Final Inspections, and Random Audit inspection records can be viewed with a double-click.

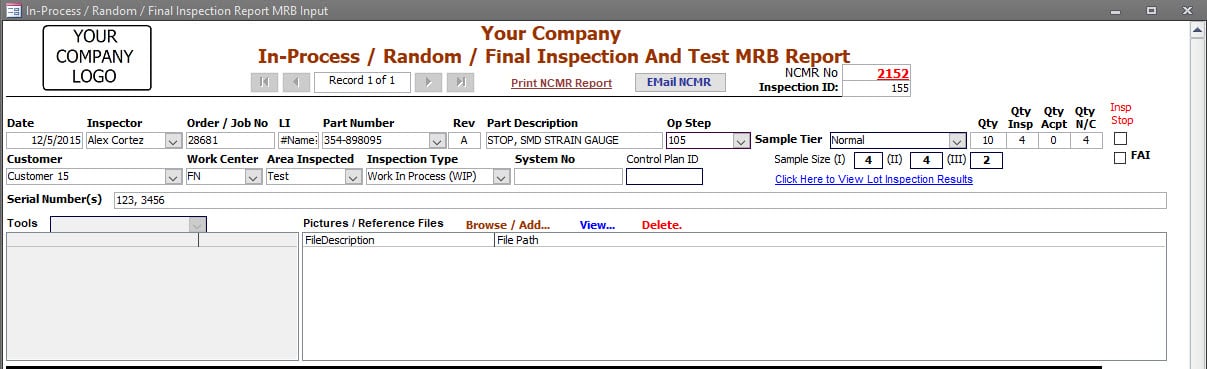

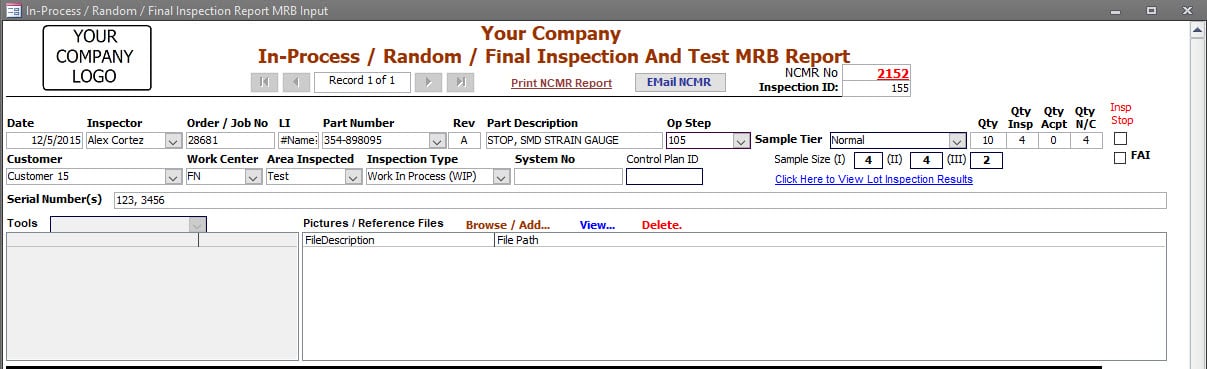

Work In Process (WIP) Inspection Information

Many standard fields are available for Work-In-Process (WIP) or Final Inspection entry. The organization should decide what information has value and should be populated. Standard fields that exist are:

Inspection Date,

Part Number, Part Description, Part Revision Level,

Work Order Number,

Lot Quantity, Quantity Inspected, Accepted, and Rejected.

Other fields, such as;

System Number,

Customer,

Work Center and Area Inspected,

Serial Numbers, and Inspection Method options such as 100% Inspection, Skip Lots, and AQL 0.5, 1.0, 1.5 C=0 sampling plans

are available depending on the organization’s inspection requirements.

When the Calibration Management Software is purchased and integrated within this Inspection and Nonconforming Material software, the tools (measurement devices) used to perform the inspection can be linked to the inspection record. This is incredibly convenient if a measurement device’s “Condition as Found” is out of specification during its calibration process. Organizations know precisely the product inspected using the measurement device and can immediately determine the effect of the inspection result based on an out-of-specification condition.

Files can be linked to each inspection. Options might include Test Results, Completed Inspection forms, or Drawings. Linked files can be viewed at any time in the future.

NOTE: If organizations want to reduce data entry, this Inspection and Non-Conforming software can maintain Work Order information through a direct link to many ERP systems or an automated sync process of Work Order information—Call Database Providers to learn more about this feature.

When this direct link or sync feature is used, many fields are pre-populated based on the Work Order Number entered by the inspector. In most cases, the Part Number, Revision Level, Description, and Work Order Quantity fields are all populated from the Work Order information.

In addition to those fields, other fields, such as Area Inspected, Work Center, Lot Code, Date Code, Serial Numbers, and System Number, can be pre-populated depending on the amount of information available by the ERP system.

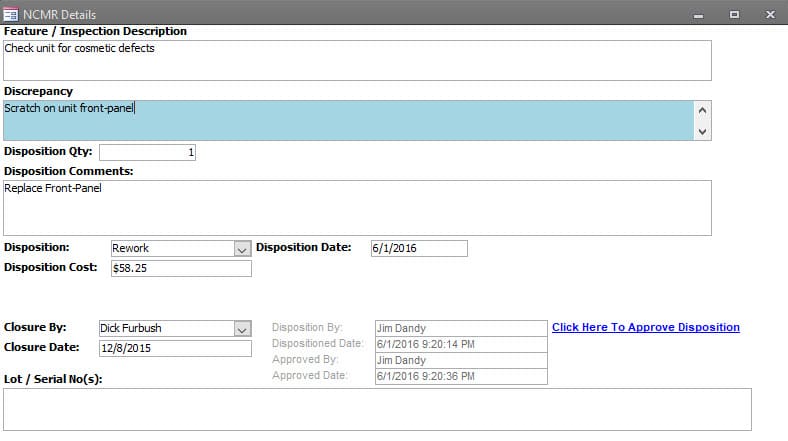

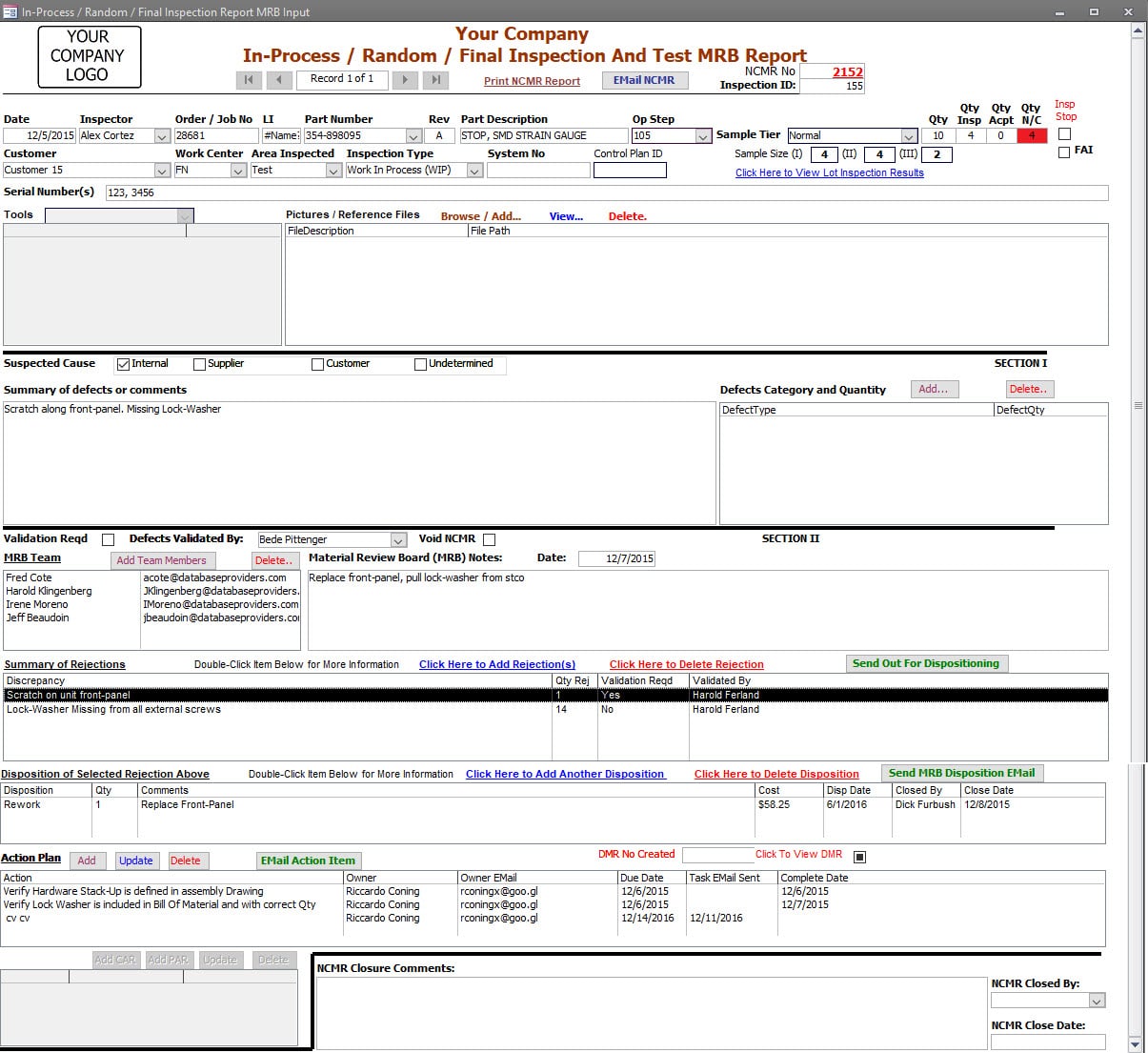

| Work In Process NonConformances

For Non-Conforming Material, the inspection record and unique NCMR ID are issued when a discrepancy is identified. The Defect Category and Quantity can be captured for Pareto Chart reporting purposes. Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings and pictures of non-conformances. An MRB Team can be identified. All Rejections within the inspected lot are documented within the inspection record. In addition, each Rejection can have Multiple Dispositions, and those dispositions are identified. (e.g., some quantity can be disposed to be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.) The one-click process to Generate and Send Emails requesting Dispositioning or to those Responsible for Executing the Disposition. If a Corrective Action is warranted, the One-Click process creates a Corrective Action and Links the corrective action record to the Inspection Record. |

|

| Work In Process (WIP) Inspection Rejection

Rejection Information contains the Expected Condition and the Discrepancy. When required, Serial Numbers can be added to the rejection record. Rejections can be flagged for validation of the discrepancy with provisions to record who performed the validation. If a Rejection warrants corrective or preventive action, that can also be flagged for creation. |

|

| Work In Process (WIP) Rejection Dispositioning

Each Rejection has its unique set of Dispositions. Disposition Information shows the Expected Condition, the Discrepancy, Disposition, Disposition Quantity, and Disposition Date. In addition, a Disposition Cost field is available for those organizations tracking Cost of Quality (CoQ). The software captures who entered the disposition. In addition, when approvals are required, the systems also capture who approved the disposition using an approval password process. When the Disposition is returned to Vendor, additional fields are available to record the supplier’s RMA Number, Buyer Information, Date the product was Shipped to the Supplier, and the Date product was Returned from the Supplier. |

|

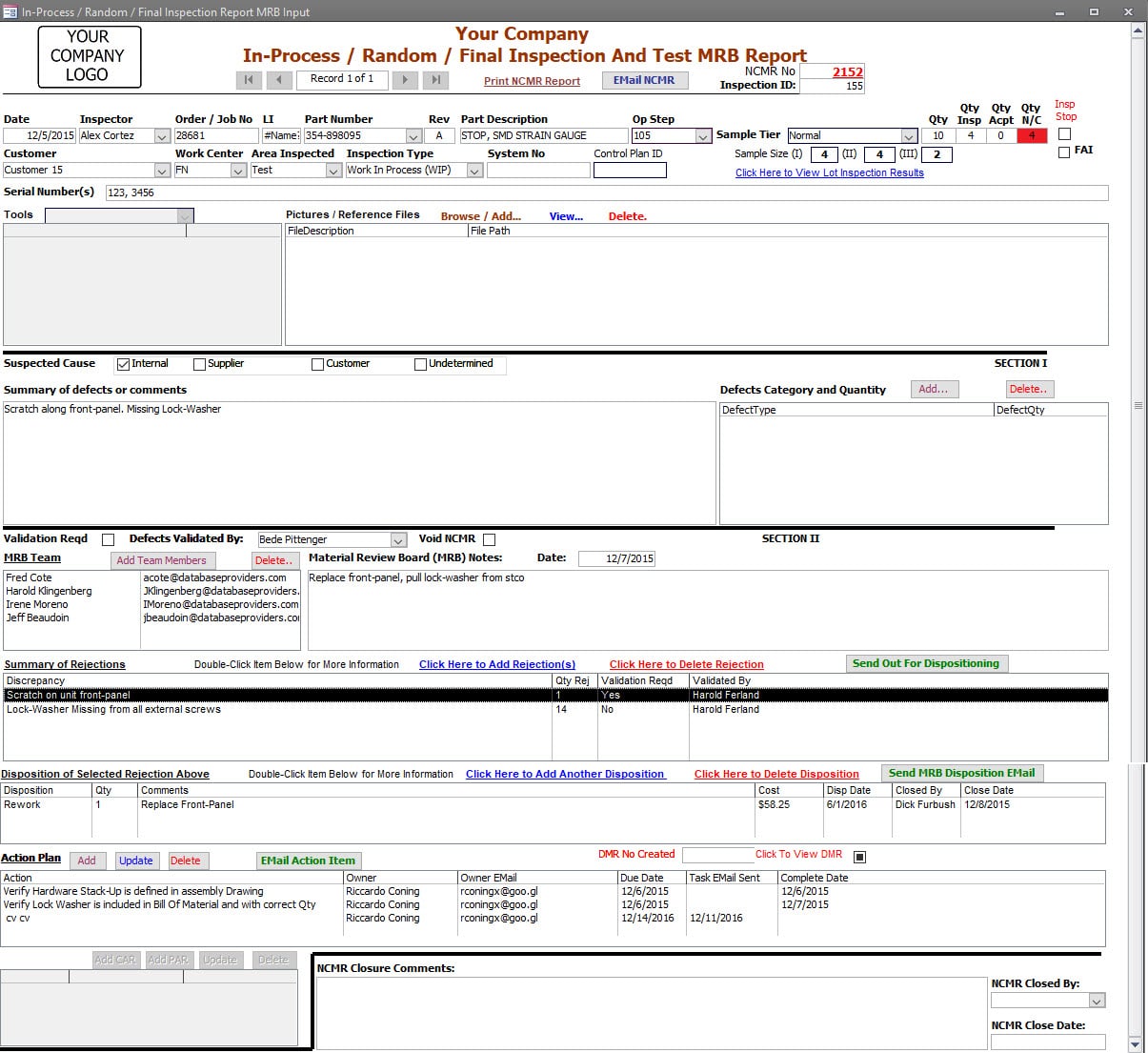

Work In Process NonConformances

For Non-Conforming Material, the inspection record and unique NCMR ID are issued when a discrepancy is identified.

The Defect Category and Quantity can be captured for Pareto Chart reporting purposes.

Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings and pictures of non-conformances.

An MRB Team can be identified.

All Rejections within the inspected lot are documented within the inspection record. In addition, each Rejection can have Multiple Dispositions, and those dispositions are identified. (e.g., some quantity can be disposed to be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.)

The one-click process to Generate and Send Emails requesting Dispositioning or to those Responsible for Executing the Disposition.

Actions (task items) can be entered and assigned to specific parties (individuals) throughout the process. Open Action Items are visible in the Dashboard.

If a Corrective Action is warranted, the One-Click process creates a Corrective Action and Links the corrective action record to the Inspection Record.

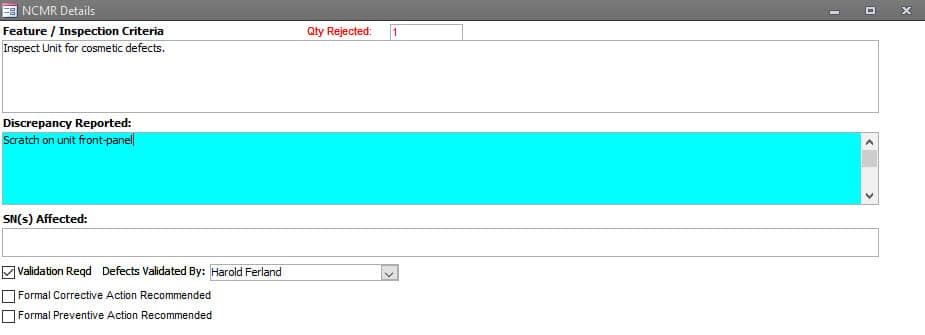

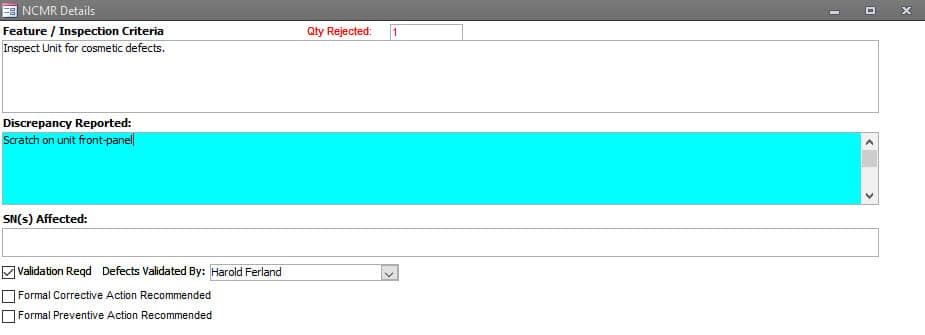

Work In Process (WIP) Inspection Rejection

Rejection Information contains the Expected Condition and the Discrepancy.

When required, Serial Numbers can be added to the rejection record.

Rejections can be flagged for validation of the discrepancy with provisions to record who performed the validation.

If a Rejection warrants corrective or preventive action, that can also be flagged for creation.

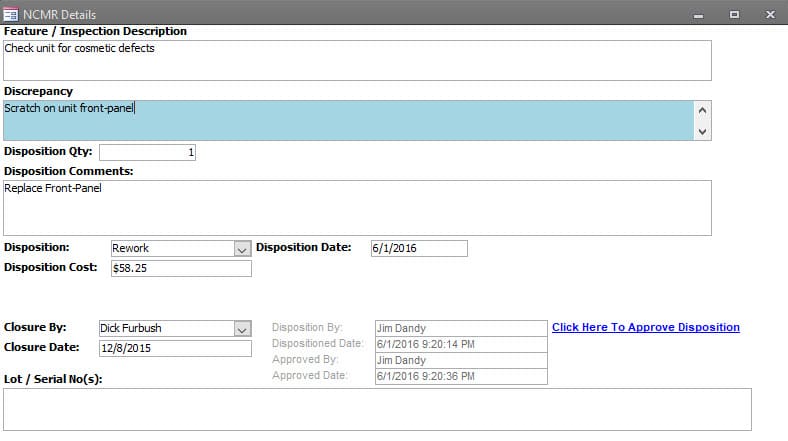

Work In Process (WIP) Rejection Dispositioning

Each Rejection has its unique set of Dispositions.

Disposition Information shows the Expected Condition, the Discrepancy, Disposition, Disposition Quantity, and Disposition Date. In addition, a Disposition Cost field is available for those organizations tracking Cost of Quality (CoQ).

The software captures who entered the disposition. In addition, when approvals are required, the systems also capture who approved the disposition using an approval password process.

When the Disposition is returned to Vendor, additional fields are available to record the supplier’s RMA Number, Buyer Information, Date the product was Shipped to the Supplier, and the Date product was Returned from the Supplier.

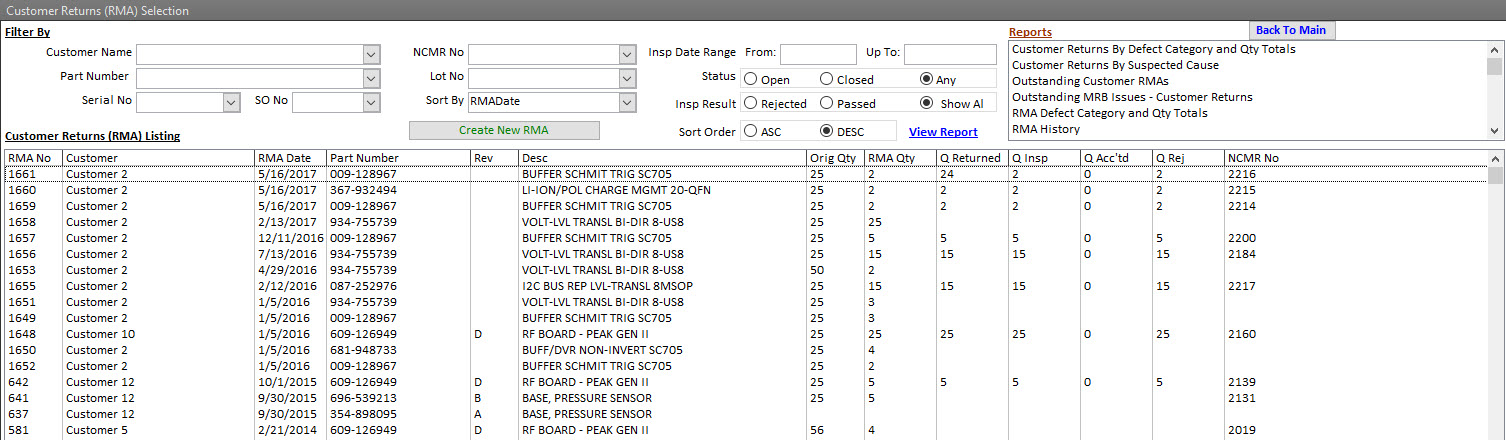

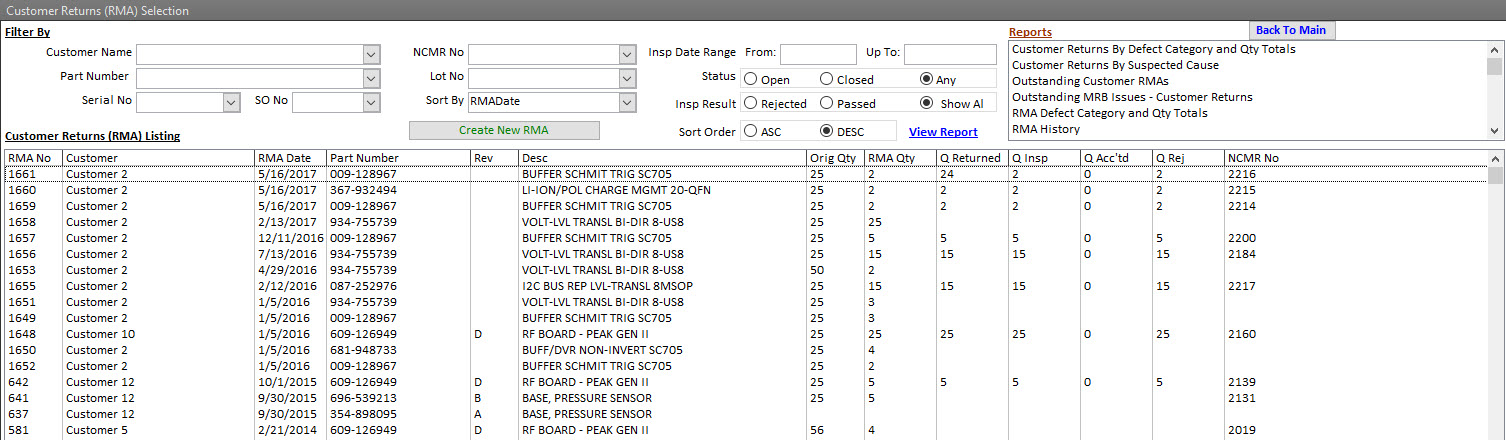

| Customer Returns (RMAs)

Customer Returns (RMA) inspection records can be searched using various fields and combinations. Reports revolving around RMA inspection records can be viewed with a double click. |

|

| Customer Return Information

Customer Returns (RMA) inspection record contains many standard fields. The organization is to decide what information has value and is to be populated. The Common fields available are: When the product is received, |

|

Customer Returns (RMAs)

Customer Returns (RMA) inspection records can be searched using various fields and combinations.

Reports revolving around RMA inspection records can be viewed with a double click.

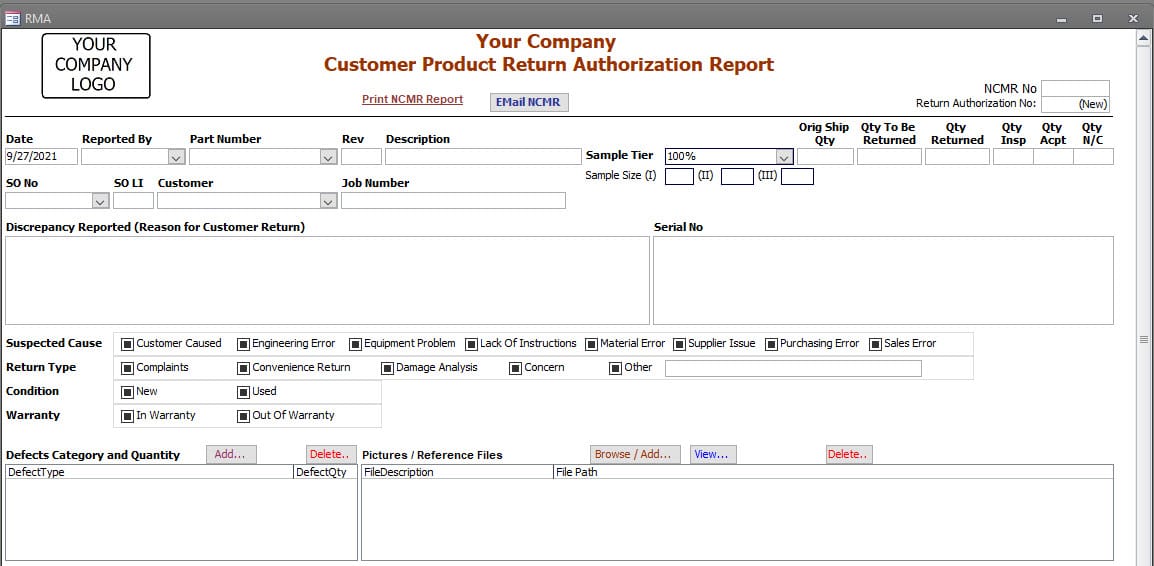

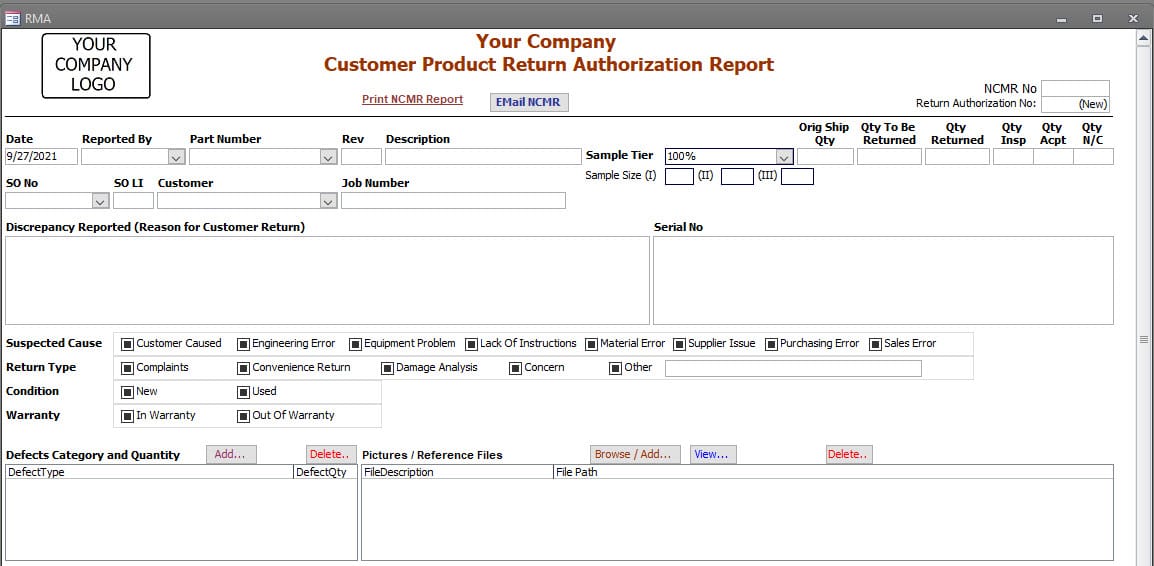

Customer Return Information

Customer Returns (RMA) inspection record contains many standard fields. The organization is to decide what information has value and is to be populated.

The Common fields available are:

RMA Date,

Part Number, Part Description, Part Revision Level,

Customer, Sales Order Number, and Line Item,

Reason for Return,

Serial Number(s),

Original Ship Quantity and Quantity to Be Returned.

When the product is received,

Date Product Received, Quantity Received, Inspected, Accepted, and Rejected are available.

Other fields are available such as:

Suspected Cause,

Return Type,

Condition Warranty Status,

Level of Inspection required,

and the Inspection Method option such as 100% Inspection, Skip Lots, Dock-To-Stock, and AQL 0.5, 1.0, 1.5 C=0 sampling plans,

depending on the organization’s requirements.

Files can be linked to each Customer Return (RMA). For example, typical Usage might include Emails, Pictures of Discrepancies, or Damage. All Linked files can be viewed at any time.

NOTE: If an organization wants to reduce data-entry and data-entry errors, this Inspection and Non-Conforming software can directly link to many ERP systems or the ability to sync to ERP data periodically—Call Database Providers to learn more about this feature.

When this direct link or sync feature is used, many fields are pre-populated based on the Sales Order Number entered by the RMA initiator. In most cases, the Part Number, Revision Level, Description, Customer, Sales Order Line Item, and Sales Order Ship Quantity fields are all populated from the Sales Order information.

| Customer Return Non-Conformances

For Non-Conforming Material, the RMA record becomes the NCM Report. The Defect Category and Quantity can be entered or verified for Pareto Chart reporting purposes. Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings and pictures of non-conformances. The MRB Team can be identified. All rejections can be identified individually. Useful when more than one discrepancy is found within the inspected lot. Each rejection can have multiple dispositions, and those dispositions are identified. (e.g., some quantity can be disposed to be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.) Those options are available for organizations that want to track material and labor on returned products. The one-click process to generate and send out an Email asking for dispositioning and another email to those responsible for executing the disposition. Actions can be entered and assigned to specific parties (individuals) throughout the process. Action items are managed through the dashboard. If a Corrective Action is warranted, the one-click process creates a corrective action and links the corrective action record to the Inspection record. |

|

| Customer Return Non-Conformances

For Non-Conforming Material, the RMA record becomes the NCM Report. The Defect Category and Quantity can be entered or verified for Pareto Chart reporting purposes. Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings and pictures of non-conformances. The MRB Team can be identified. All rejections can be identified individually. Useful when more than one discrepancy is found within the inspected lot. Each rejection can have multiple dispositions, and those dispositions are identified. (e.g., some quantity can be disposed to be reworked internally due to production demand, and the rest of the quantity can be dispositioned to return to the vendor for repair or replacement.) Those options are available for organizations that want to track material and labor on returned products. The one-click process to generate and send out an Email asking for dispositioning and another email to those responsible for executing the disposition. Actions can be entered and assigned to specific parties (individuals) throughout the process. Action items are managed through the dashboard. If a Corrective Action is warranted, the one-click process creates a corrective action and links the corrective action record to the Inspection record. |

|

| Work in Process Defects

Organizations can keep track of issues found and resolved outside of an actual nonconforming record. The content of what is recorded can be customized to the requirements of the organizations. Issues can be viewed by any combination of the information added. |

|

Work in Process Defects

Organizations can keep track of issues found and resolved outside of an actual nonconforming record. The content of what is recorded can be customized to the requirements of the organizations. Issues can be viewed by any combination of the information added.