Preventive Maintenance Software

Streamline Equipment Performance and Minimize DowntimeA comprehensive solution designed to manage all your preventive maintenance tasks, schedules, and unplanned repairs with ease.

Preventive Maintenance Core Features

Get a glimpse of the key components of our Preventive Maintenance System.

- Definition

- Information

- Requirements

- Completion

- Downtime

- History

- Scheduling

- Navigation

- Setup

- Work Order

- Service Order

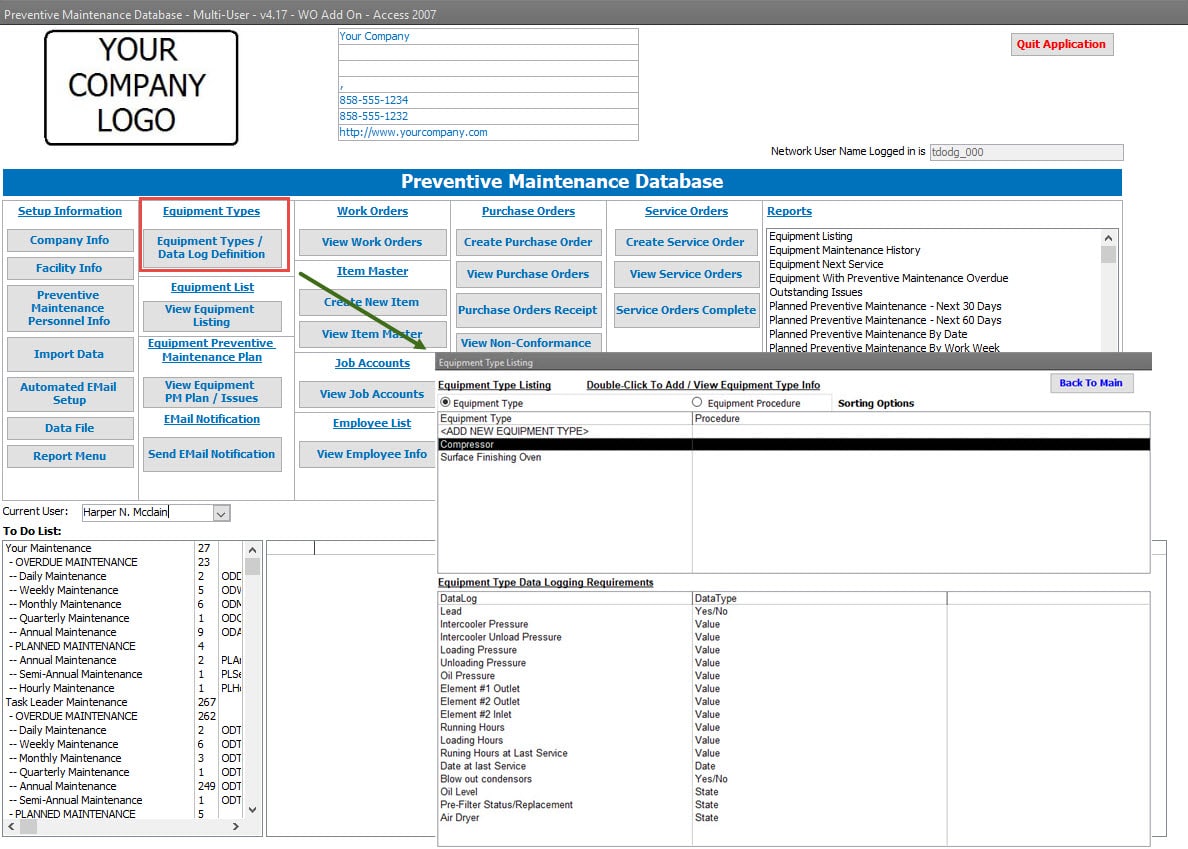

Categorize information by adding an unlimited number of asset or equipment types, linking documents, and defining fields for data logging or equipment status logging.

- Streamlined categorization and retrieval.

- Seamless tracking of equipment status and data logs.

- Optimized management of an unlimited number of equipment types.

- Customize classification to match your specific needs.

- Ensure accurate data logging and equipment status reporting.

- Enhance maintenance planning and analysis.

| Book A Demo | More Details |

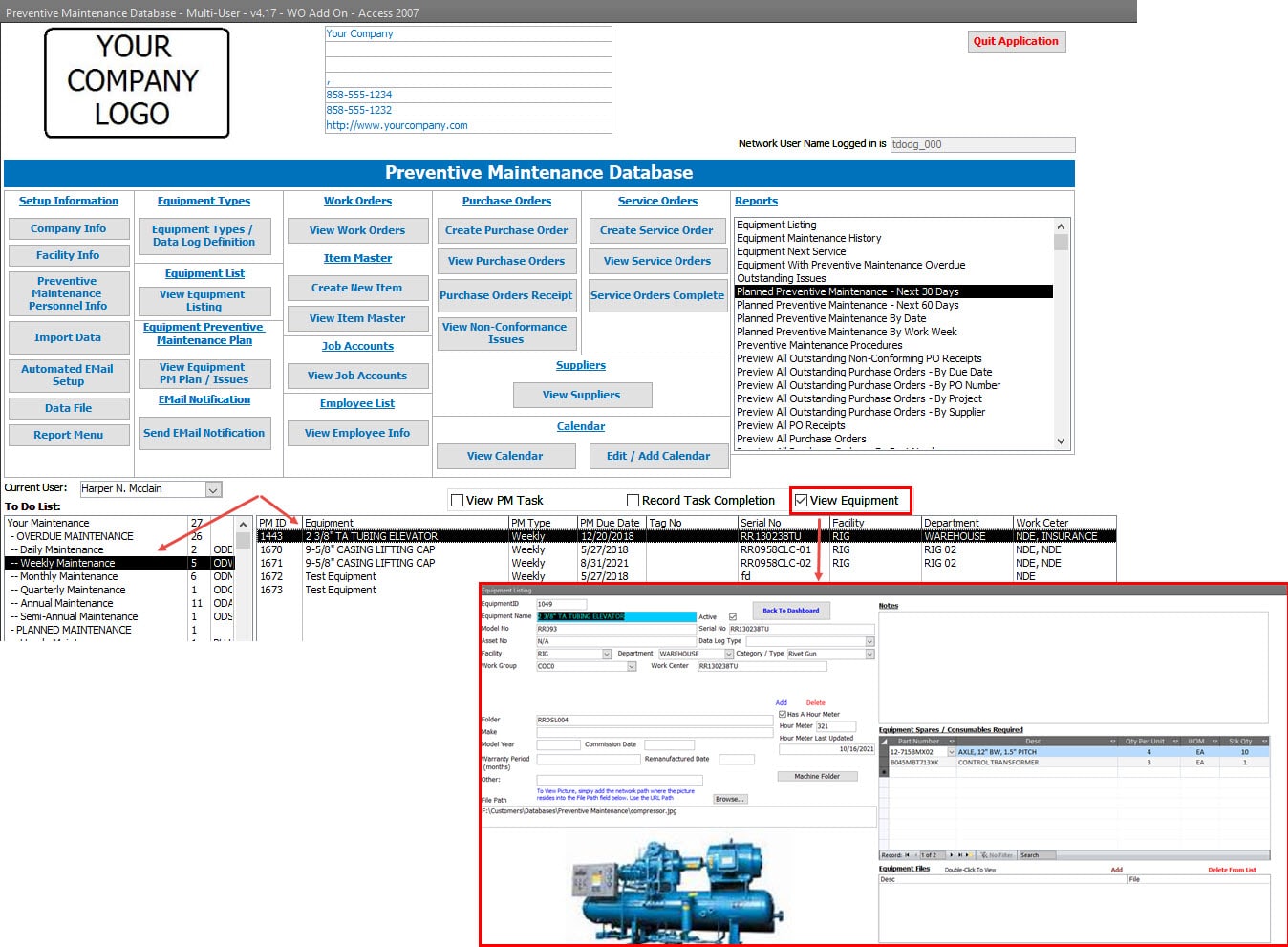

Add extensive details for each asset or equipment, including model numbers, serial numbers, make, year, location, warranty period, pictures, manuals, preventive maintenance schedules, and more.

- Detailed understanding of every asset and equipment.

- Quick access to crucial information like warranty periods and maintenance schedules.

- Easy retrieval of asset documentation such as manuals and pictures.

- Efficient tracking of asset location and status.

- Standardize identification and categorization for easy reference.

- Attach files and documents for quick access to critical information.

- Utilize data logging for comprehensive equipment reporting.

- Optimize maintenance with hour meter tracking and spare parts management.

| Book A Demo | More Details |

Define maintenance requirements for each asset and equipment, including frequency, responsible parties, procedure instructions, and more.

- Customizable maintenance requirements to suit each asset.

- Clear assignment of responsibilities for maintenance tasks.

- Access to procedure instructions for efficient task completion.

- Facilitate regular data log entries for accurate equipment assessment.

- Implement proactive maintenance strategies for asset reliability.

- Define frequency, assign responsibility, and automate reporting.

- Ensure adherence to maintenance procedures and checklists.

| Book A Demo | More Details |

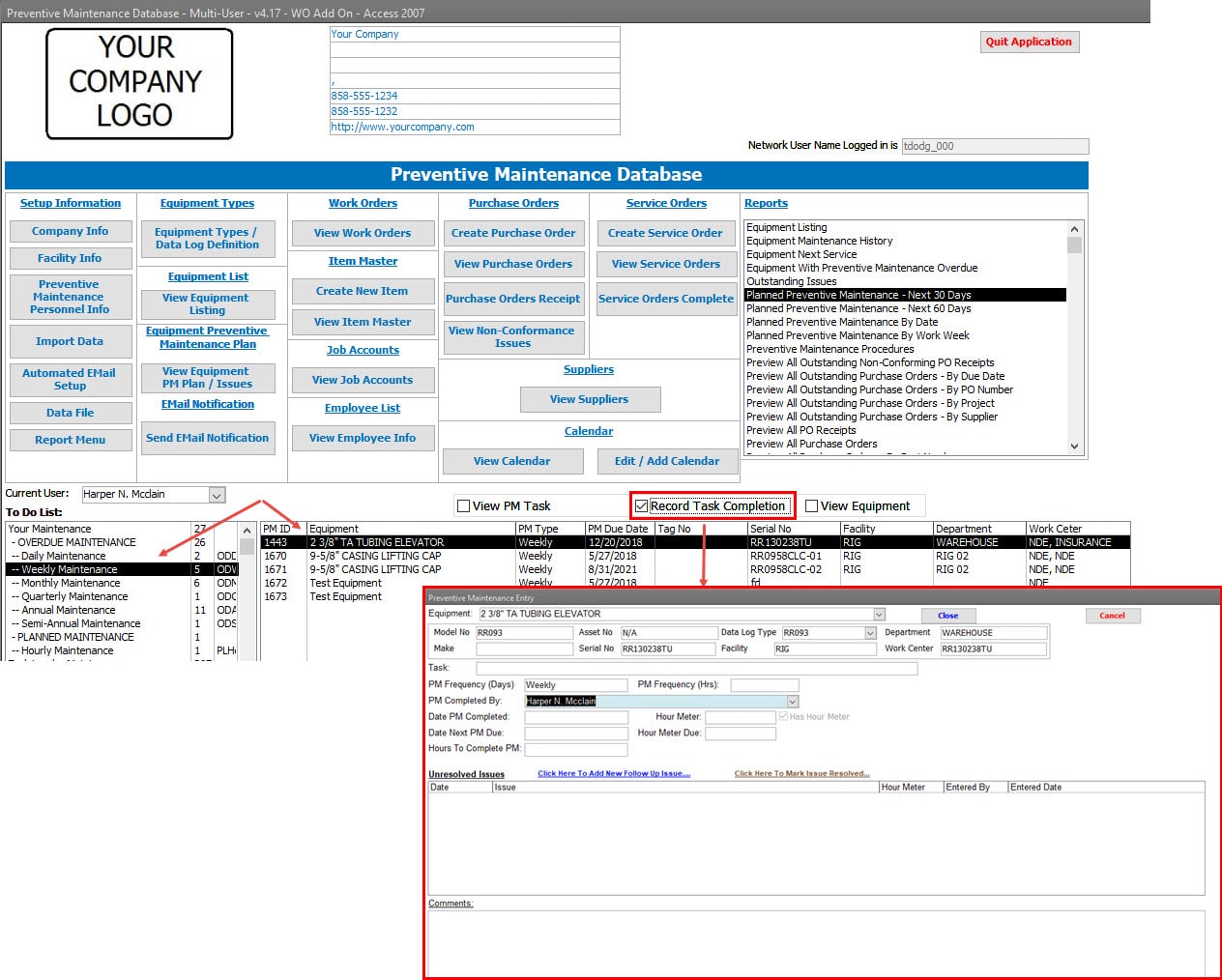

Track and record maintenance activities, such as who performed the maintenance, when it was completed, how long it took, and the setting of the next due date.

- Comprehensive record keeping of all maintenance activities.

- Real-time updates on task completions and due dates.

- Insight into task duration and staff productivity.

- Maintenance history for performance tracking and future planning.

- Streamline certifications, purchase orders, and packing lists.

| Book A Demo | More Details |

Efficiently record and manage unplanned maintenance. Log requests for repairs, record unplanned downtime and document the completion of repairs.

- Streamline the process of requesting and tracking equipment repairs.

- Automated email notifications for a prompt response.

- Detailed logs of repair requests and completions.

- Clear documentation of unplanned downtime.

- Minimized disruption with prompt repair task initiation.

| Book A Demo | More Details |

Review planned and unplanned maintenance performed on assets and equipment.

- Effective management of unexpected maintenance needs.

- Enhance maintenance planning and resource allocation.

- Detailed logs of repair requests and completions.

- Clear documentation of unplanned downtime.

- Minimized disruption with prompt repair task initiation.

| Book A Demo | More Details |

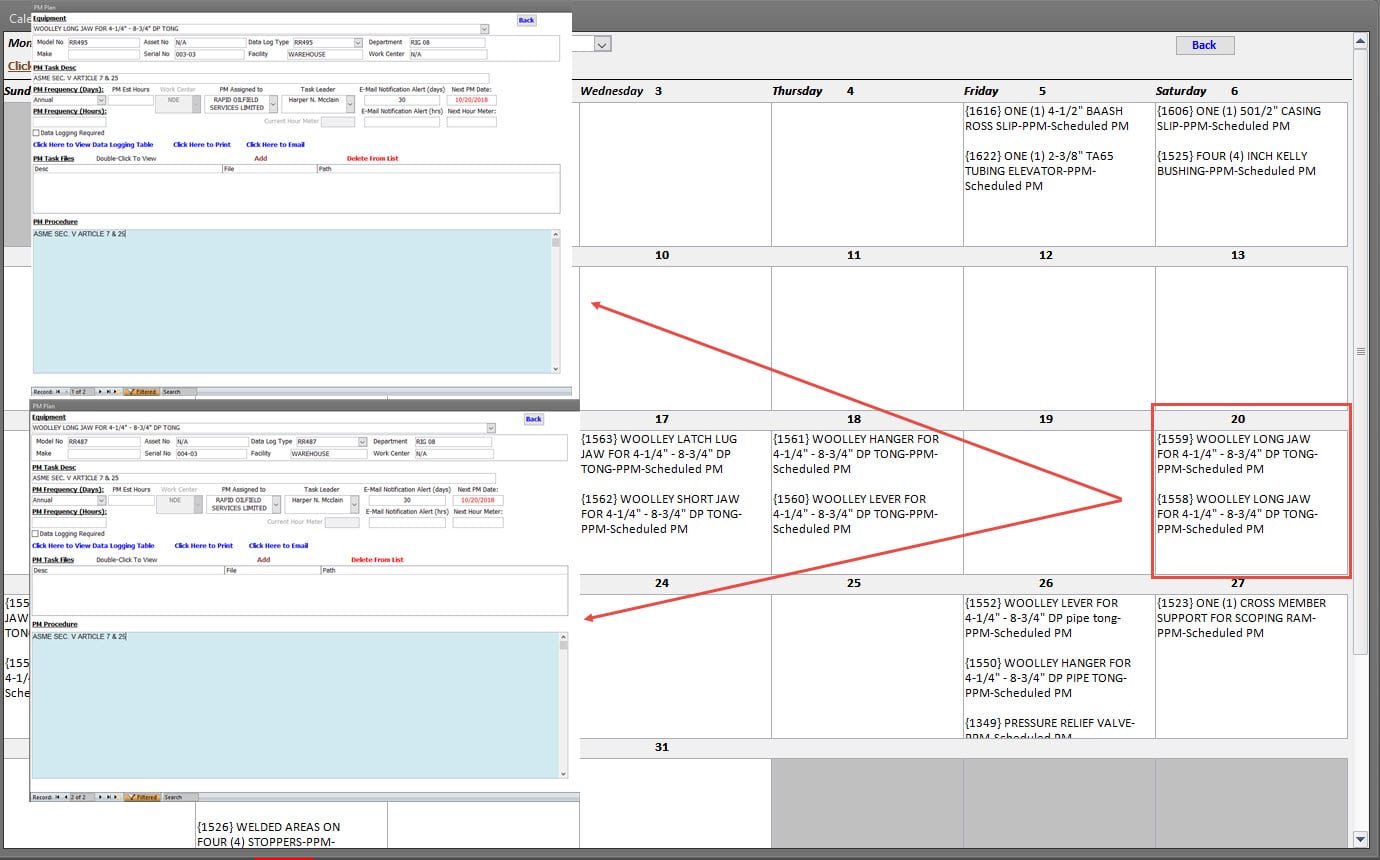

Offers a calendar view of all upcoming planned preventive maintenance tasks.

- Visualize upcoming tasks and schedule maintenance.

- User-friendly calendar interface for efficient scheduling.

- Simplified tracking of all maintenance activities.

- Enhanced productivity with well-planned task timelines.

- Navigate the calendar by day, month, and year for easy planning.

- Access detailed task information with a single click.

| Book A Demo | More Details |

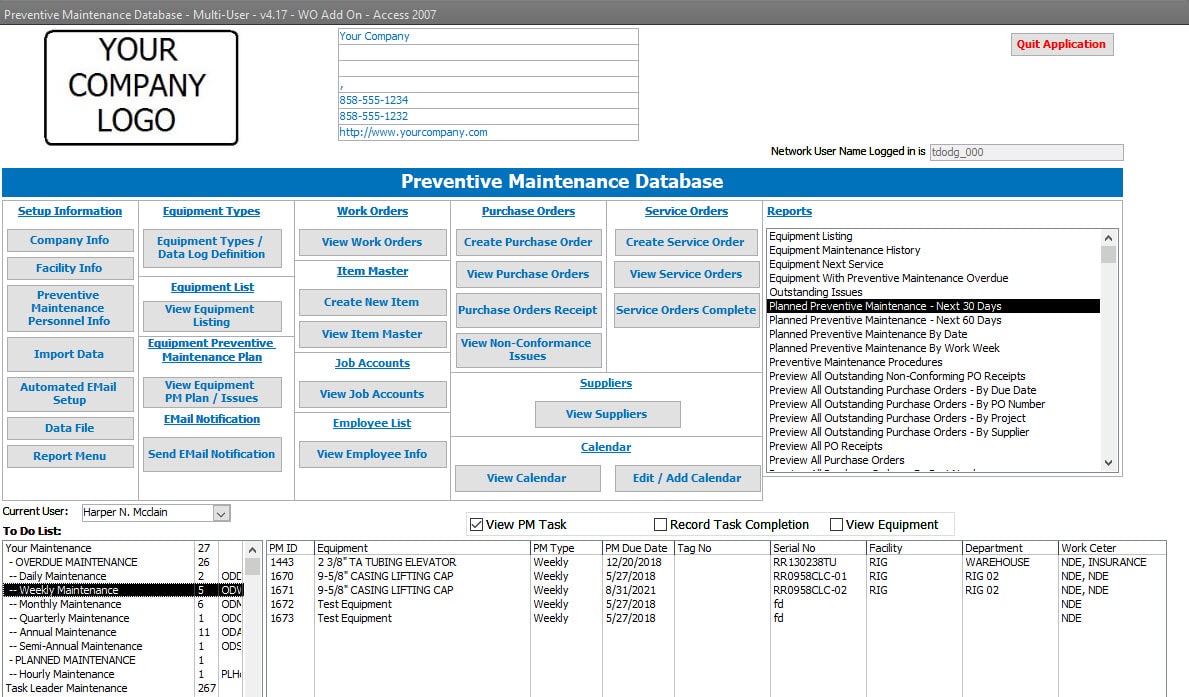

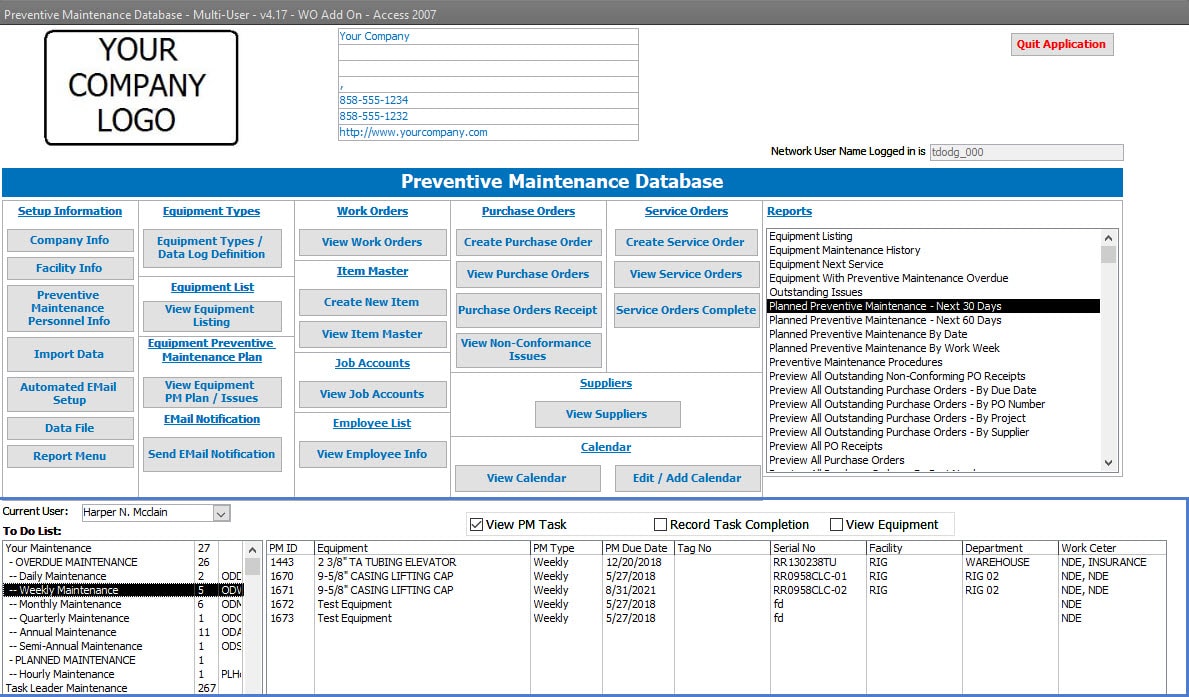

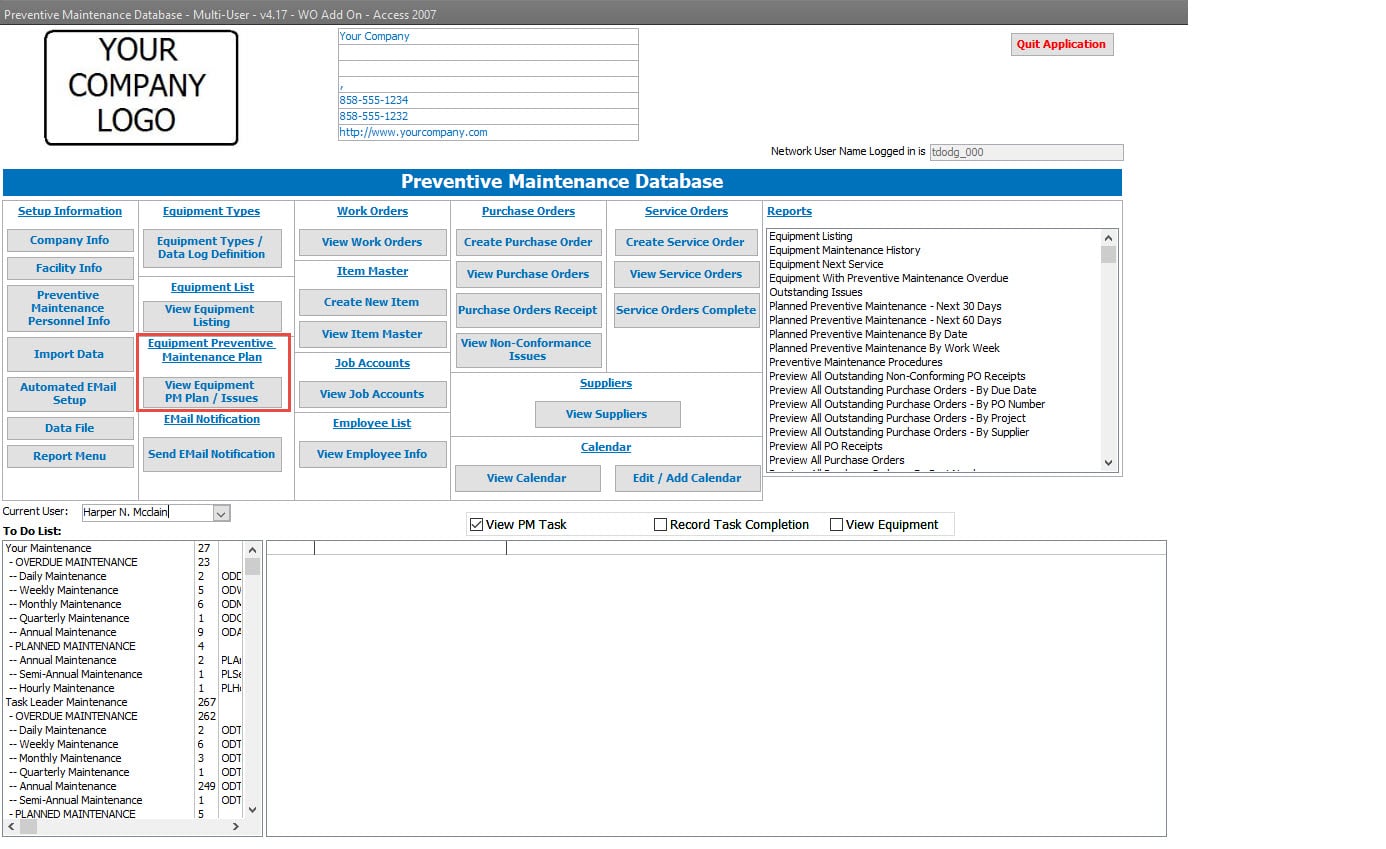

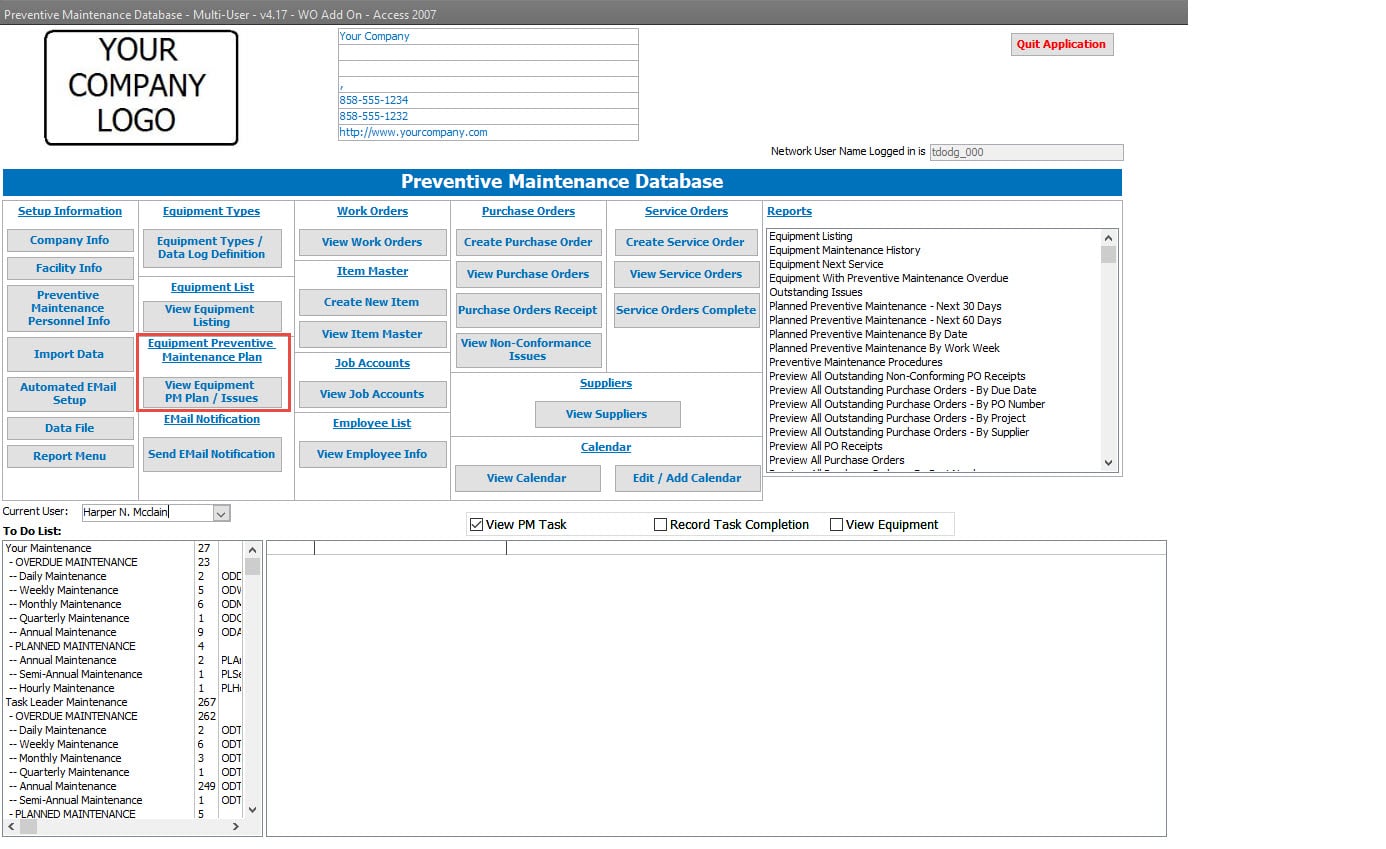

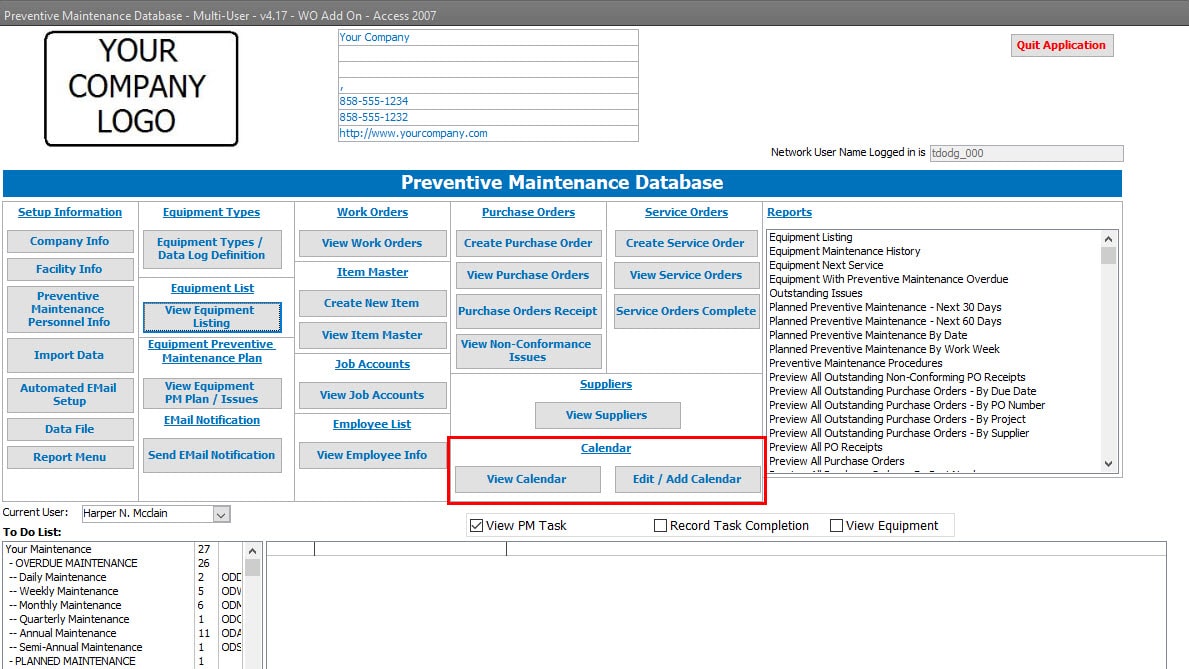

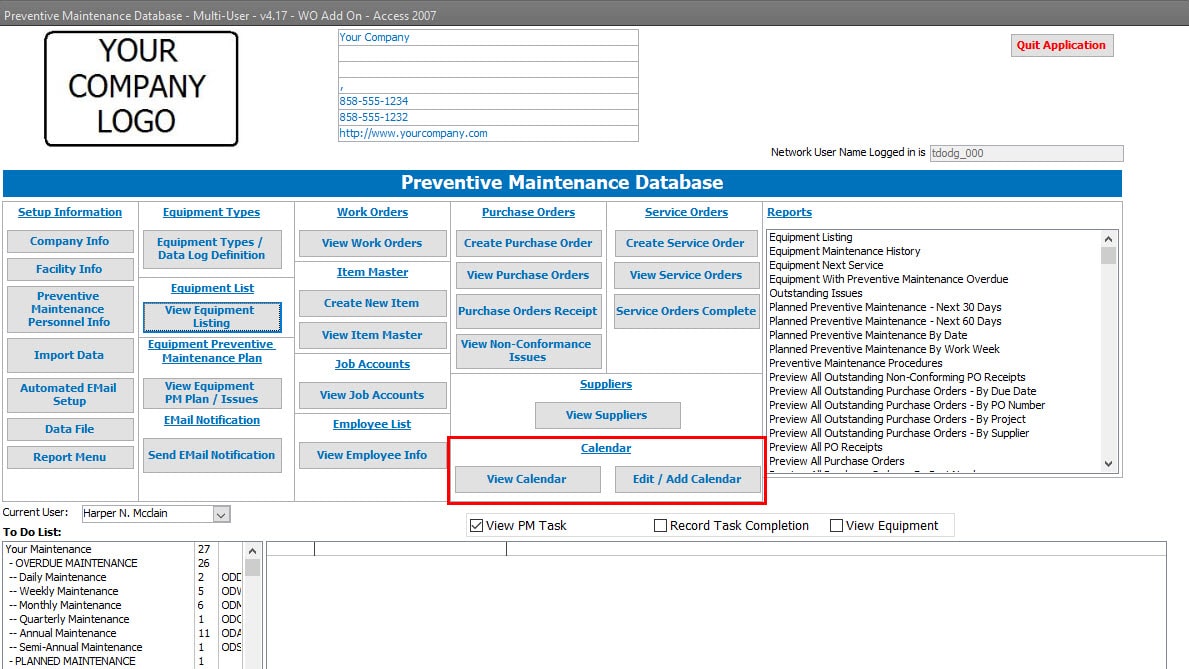

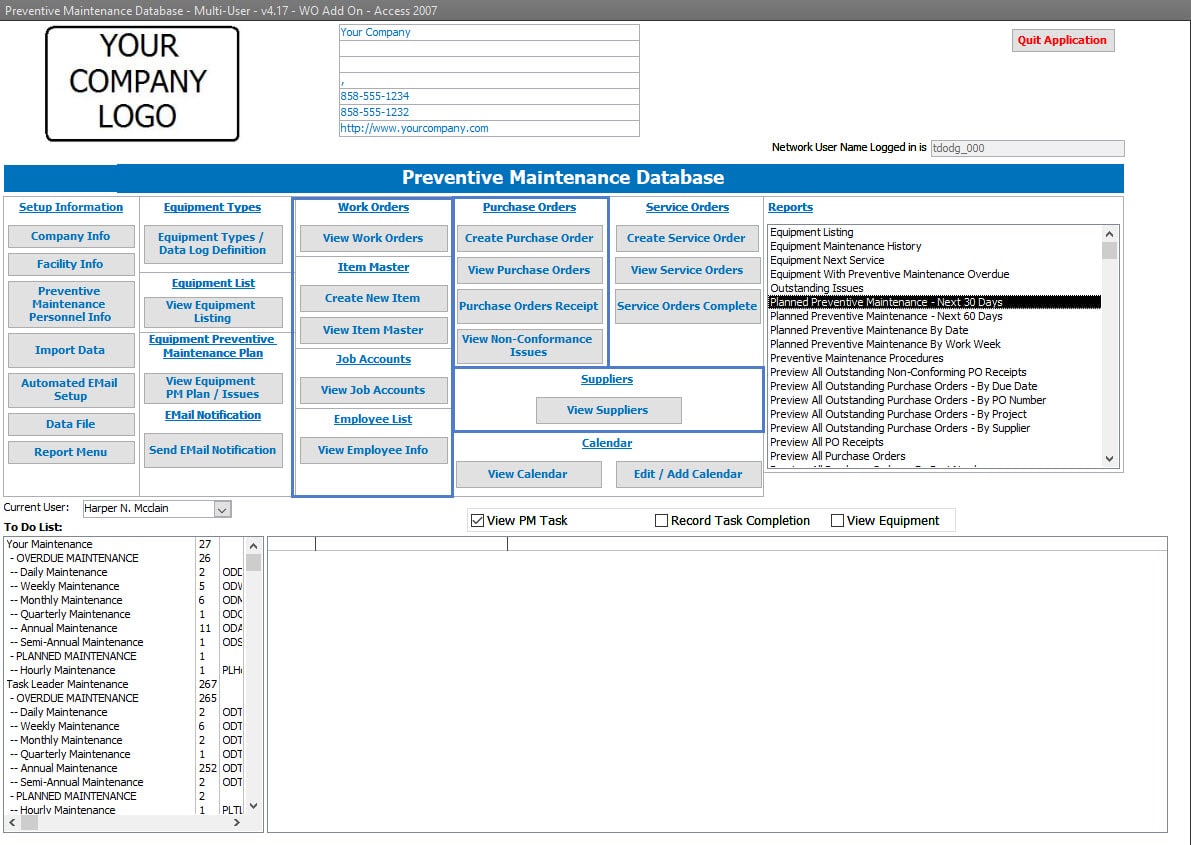

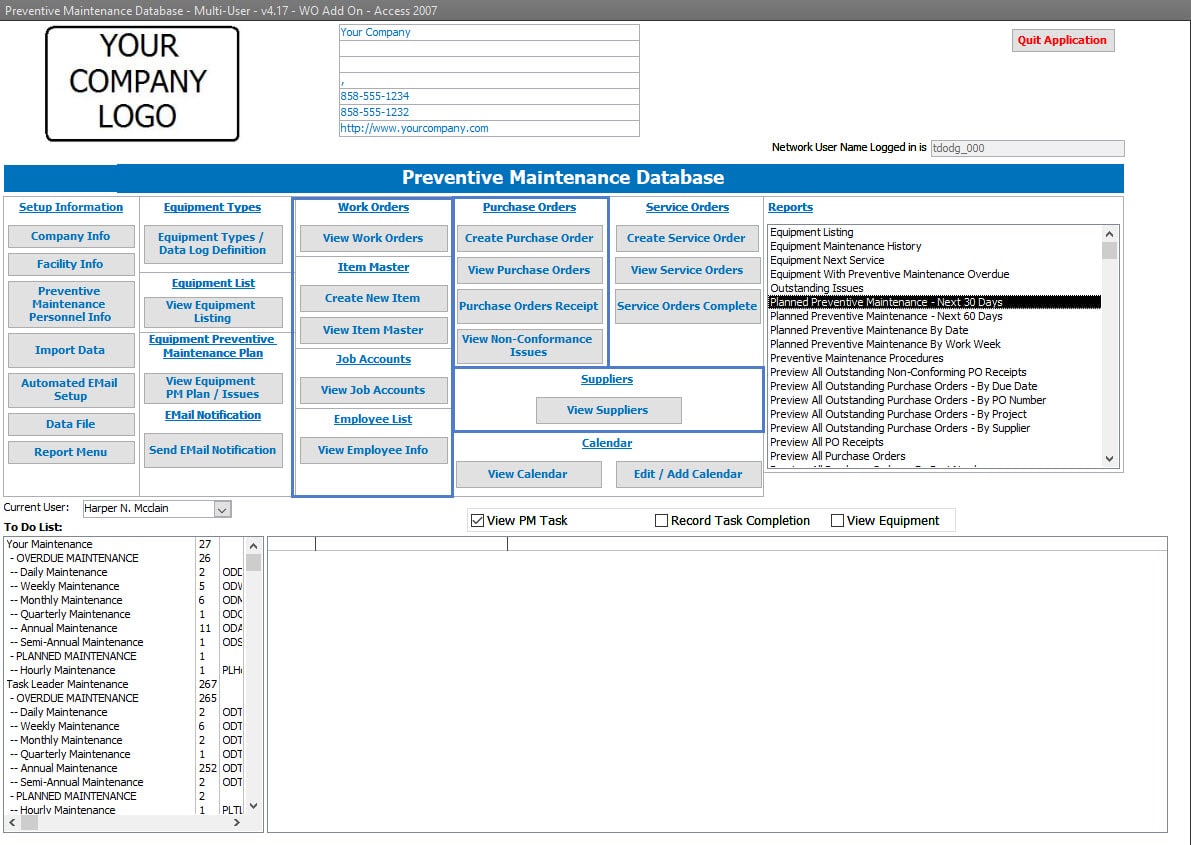

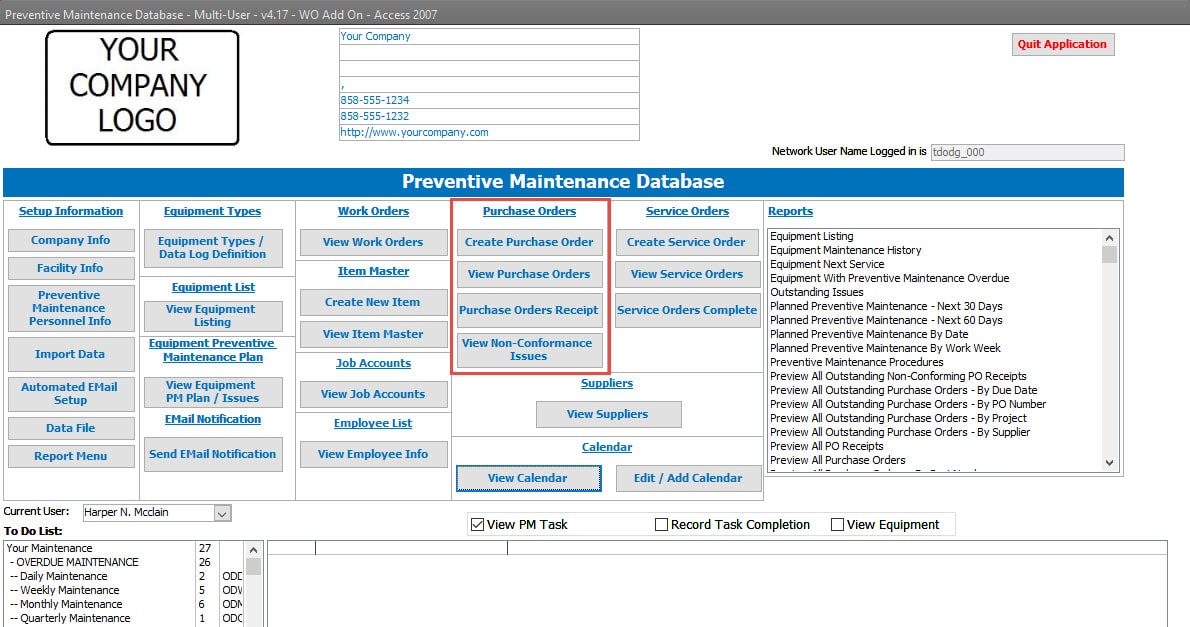

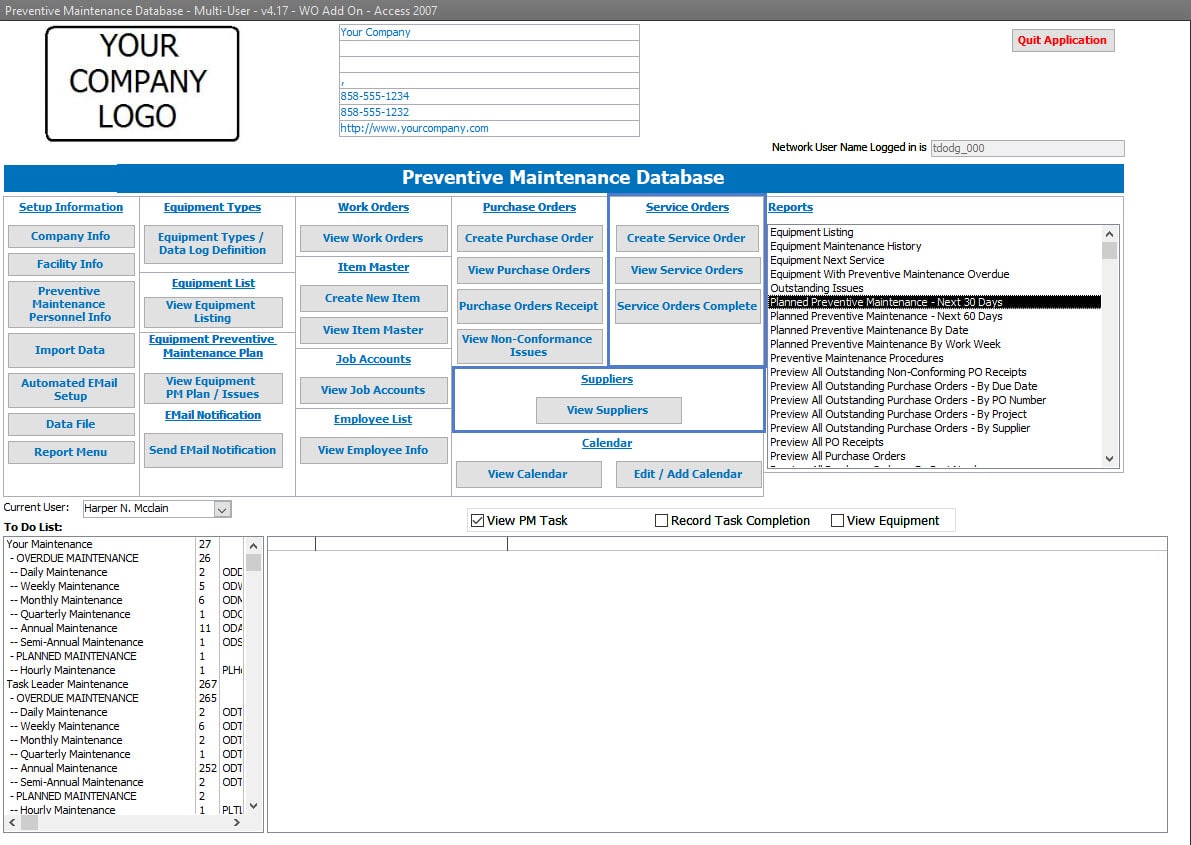

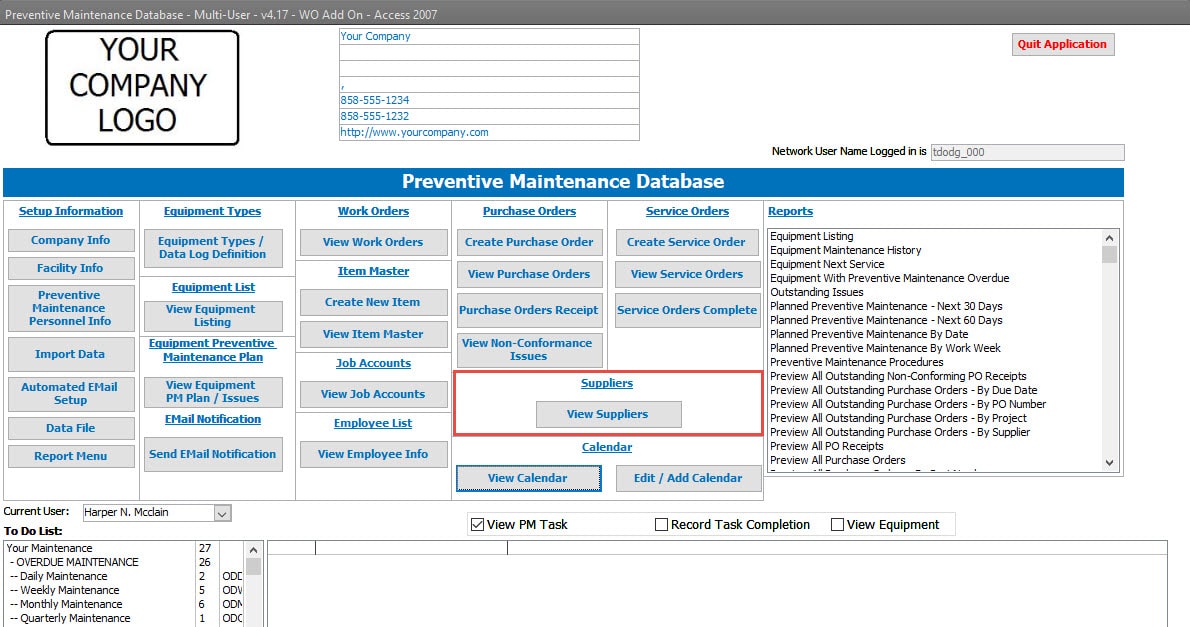

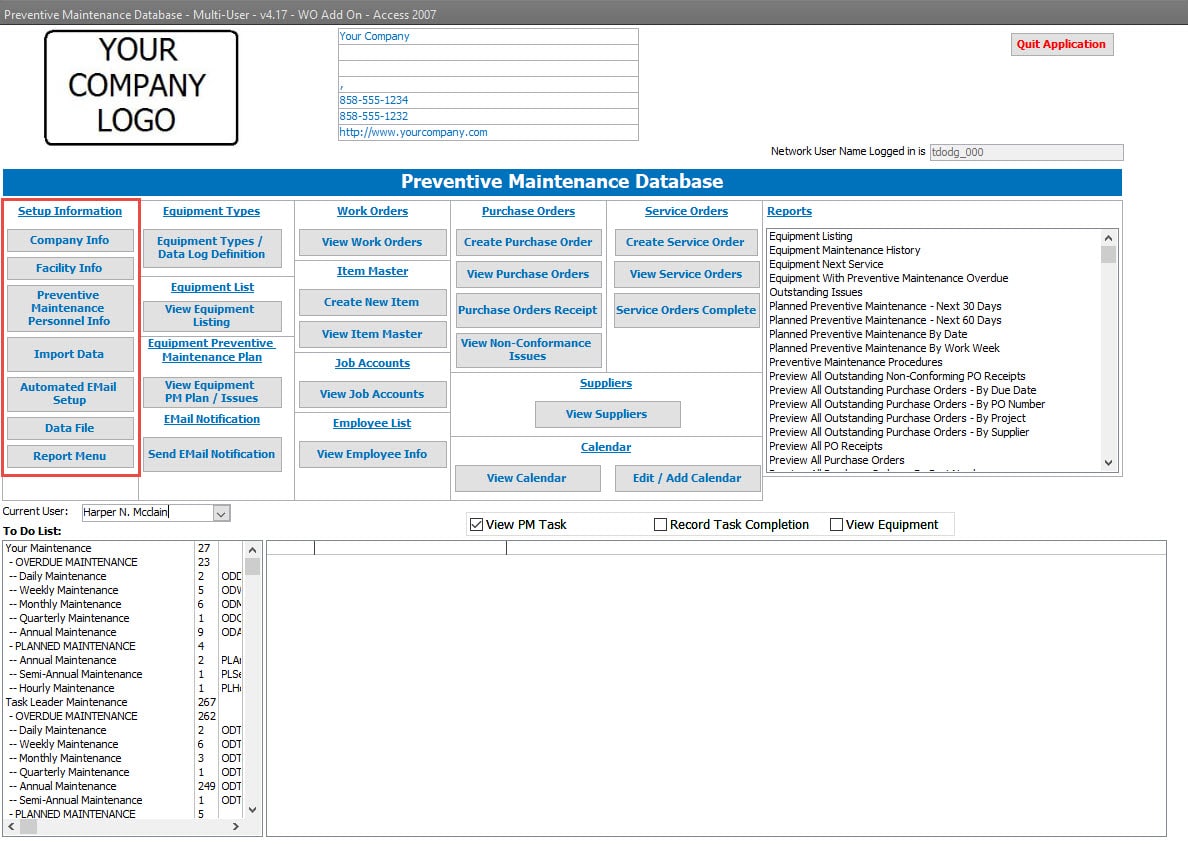

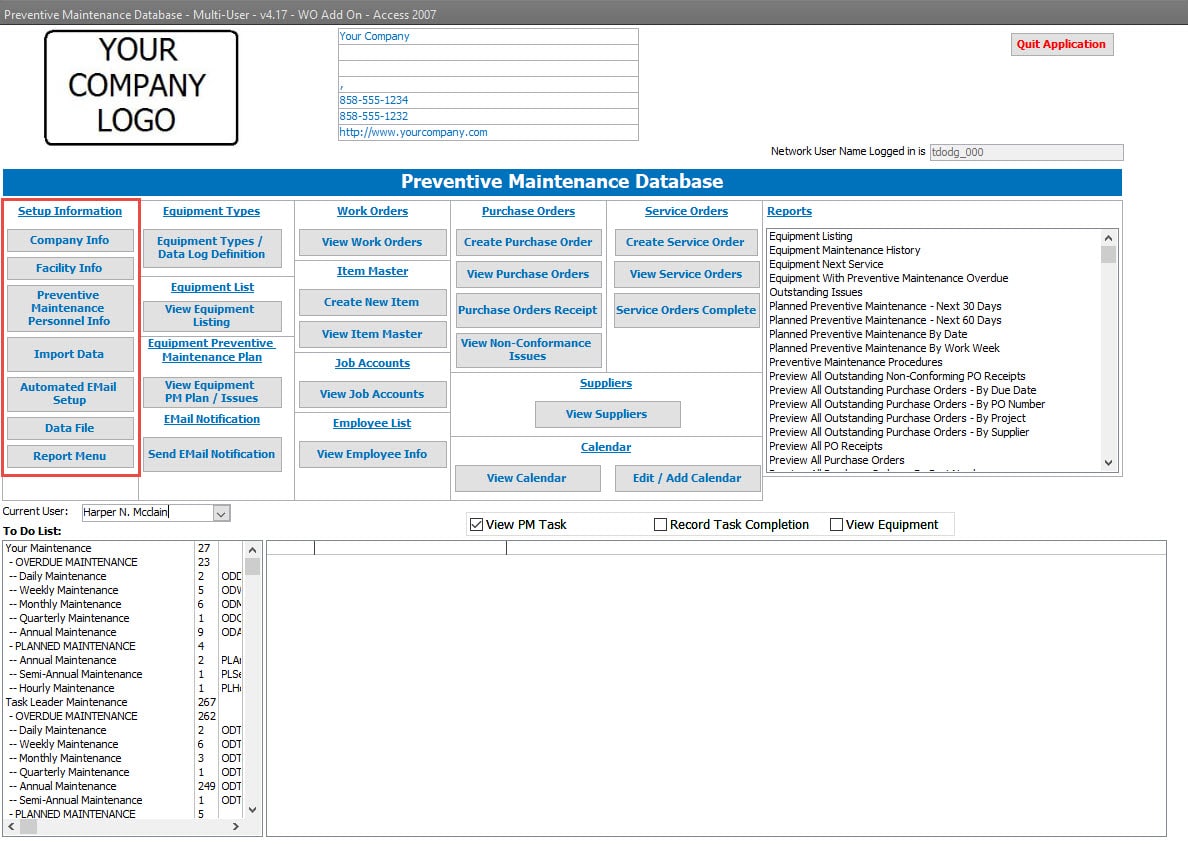

Provides a user-friendly interface for viewing and managing maintenance requirements, assets, equipment, and repair requests.

- Efficient management of maintenance tasks with easy navigation.

- Quick access to vital information through a user-friendly interface.

- Streamlined process of asset and repair request management.

- Empowers users to have complete control over their assets and maintenance tasks.

- Instantly view maintenance requirements and open repair requests.

- Quickly identify expired and upcoming planned maintenance tasks.

| Book A Demo | More Details |

Allows customization of the software with the company’s information and logo.

- Personalized experience with company-specific software setup.

- Enhanced brand visibility with the option to add your logo.

- Tailored software experience to suit your business needs.

- Easy integration with your company’s existing processes and procedures.

| Book A Demo | More Details |

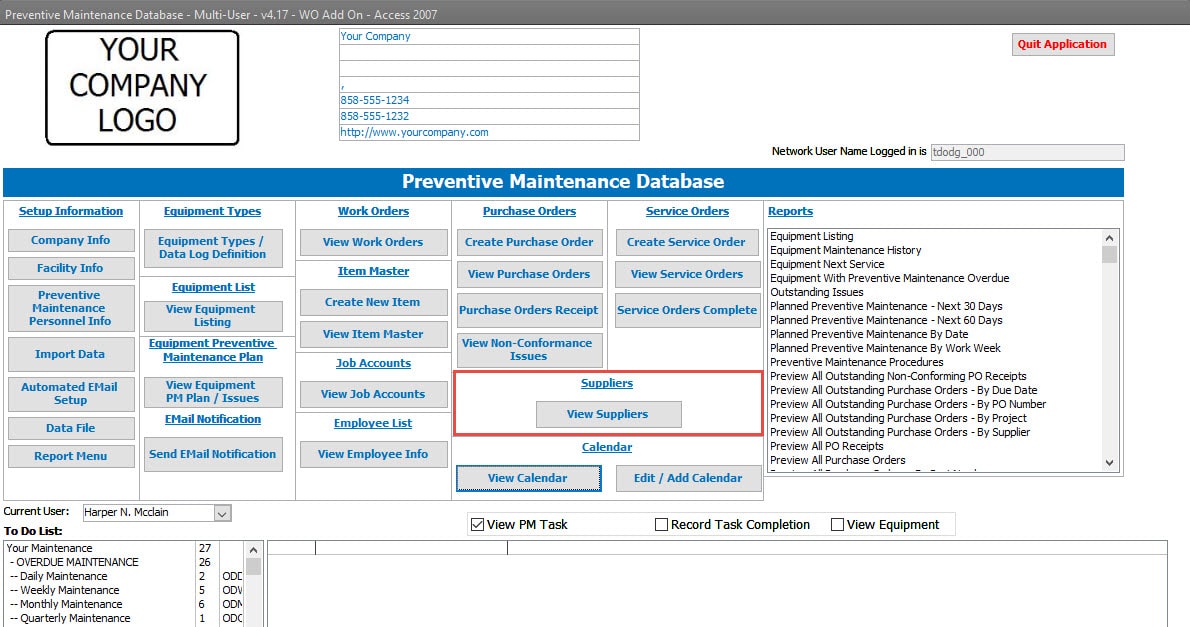

Manage planned or unplanned maintenance work orders, inventory items, suppliers, purchase orders, and total costs of the preventive maintenance program.

- Comprehensive management of work orders and inventory.

- Efficient tracking of maintenance costs.

- Clear documentation of purchase orders and supplier details.

- Ensures smooth running of your preventive maintenance program.

| Book A Demo | More Details |

Manages service orders to third-party suppliers for asset or equipment repair or maintenance.

- Streamlined management of third-party service orders.

- Efficient tracking of external maintenance or repair services.

- Better collaboration with external suppliers.

- Ensures timely repairs and maintenance by third-party providers.

- These features provide the foundation for a comprehensive and efficient preventive maintenance program, enabling you to streamline maintenance operations, reduce downtime, improve asset reliability, and optimize resource allocation.

| Book A Demo | More Details |

Why Choose Us?

Enhanced Equipment Reliability

Minimize the risk of equipment failure and associated downtime.

Efficient Data Logging

Accurately log and report equipment conditions for effective maintenance.

Streamlined Maintenance Management

Simplify scheduling, tracking, and management of preventive maintenance tasks.

Best-in-Class Customer Service and Support

Experience 100% USA-based support.

Cost Savings

Reduce equipment repair or replacement costs by proactively maintaining assets.

Simple Navigation

User-friendly interface for viewing and managing maintenance requirements, assets, equipment, and repair requests.

Automation

Benefit from automated email notifications and updated maintenance dates and calendars.

Robust Reporting

Generate user-filterable reports for planned and unplanned maintenance, costs, inventory, and more.

Setup and Personalization

Customize the software with your company’s information, logo, and configurations.

Unlock operational efficiency with our dynamic preventive maintenance management software. Experience seamless operation and boosted productivity like never before.

Take control of your maintenance operations

Unlock the power of proactive maintenance with our Preventive Maintenance Software. Experience the benefits of streamlined processes, enhanced asset reliability, and reduced downtime. Contact us today to schedule a personalized demo and see how our software can revolutionize your maintenance management.

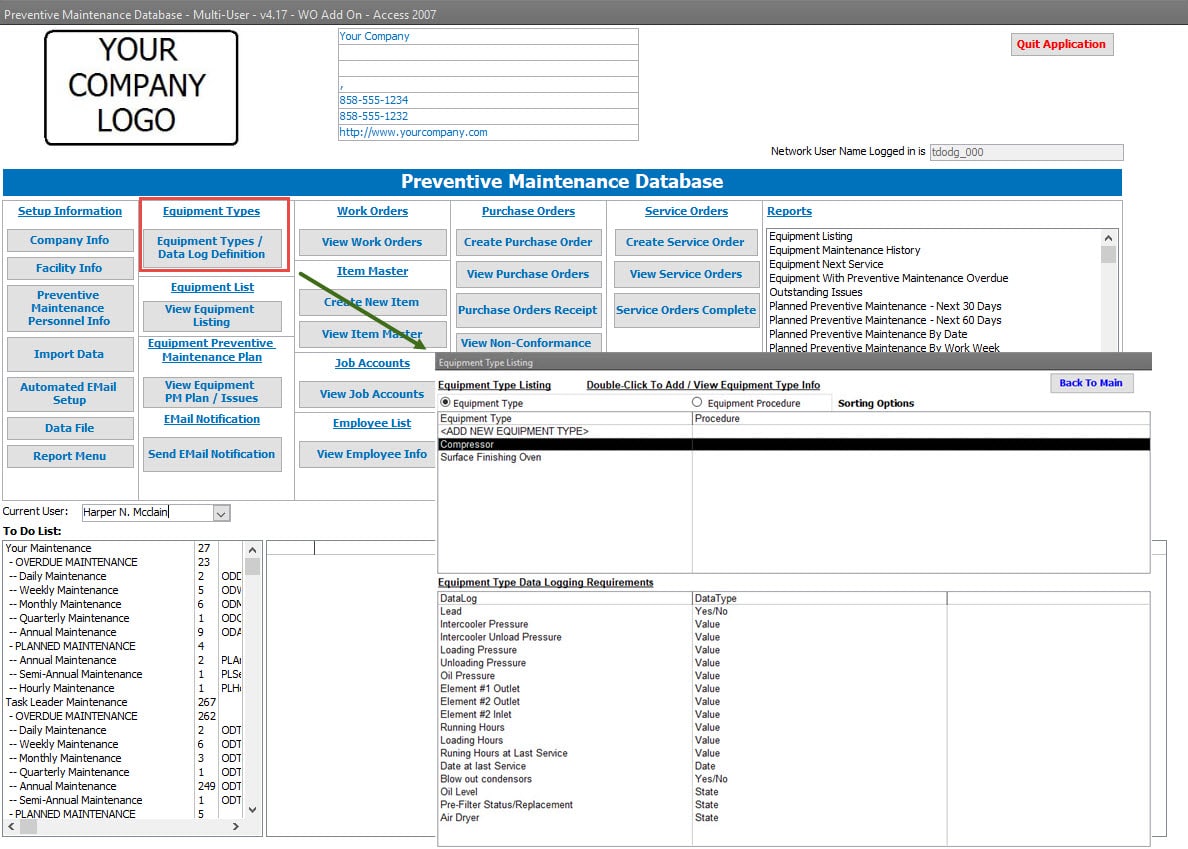

| Equipment Type Definition

Equipment Types can be added and managed. Each piece of equipment can be assigned to an equipment type. Each Equipment Type can have a data log defined for it. A data log is a unique table (spreadsheet view) created and can be assigned to a specific [piece of equipment within the Preventive Maintenance Tasks. This table is this used to capture readings taken from a piece of equipment regularly. This, in conjunction with preventive maintenance tasks and repair entries, can assist in predicting failures. |

|

Equipment Type Definition

Equipment Types can be added and managed. Each piece of equipment can be assigned to an equipment type.

Each Equipment Type can have a data log defined for it. A data log is a unique table (spreadsheet view) created and can be assigned to a specific [piece of equipment within the Preventive Maintenance Tasks. This table is this used to capture readings taken from a piece of equipment regularly.

This, in conjunction with preventive maintenance tasks and repair entries, can assist in predicting failures.

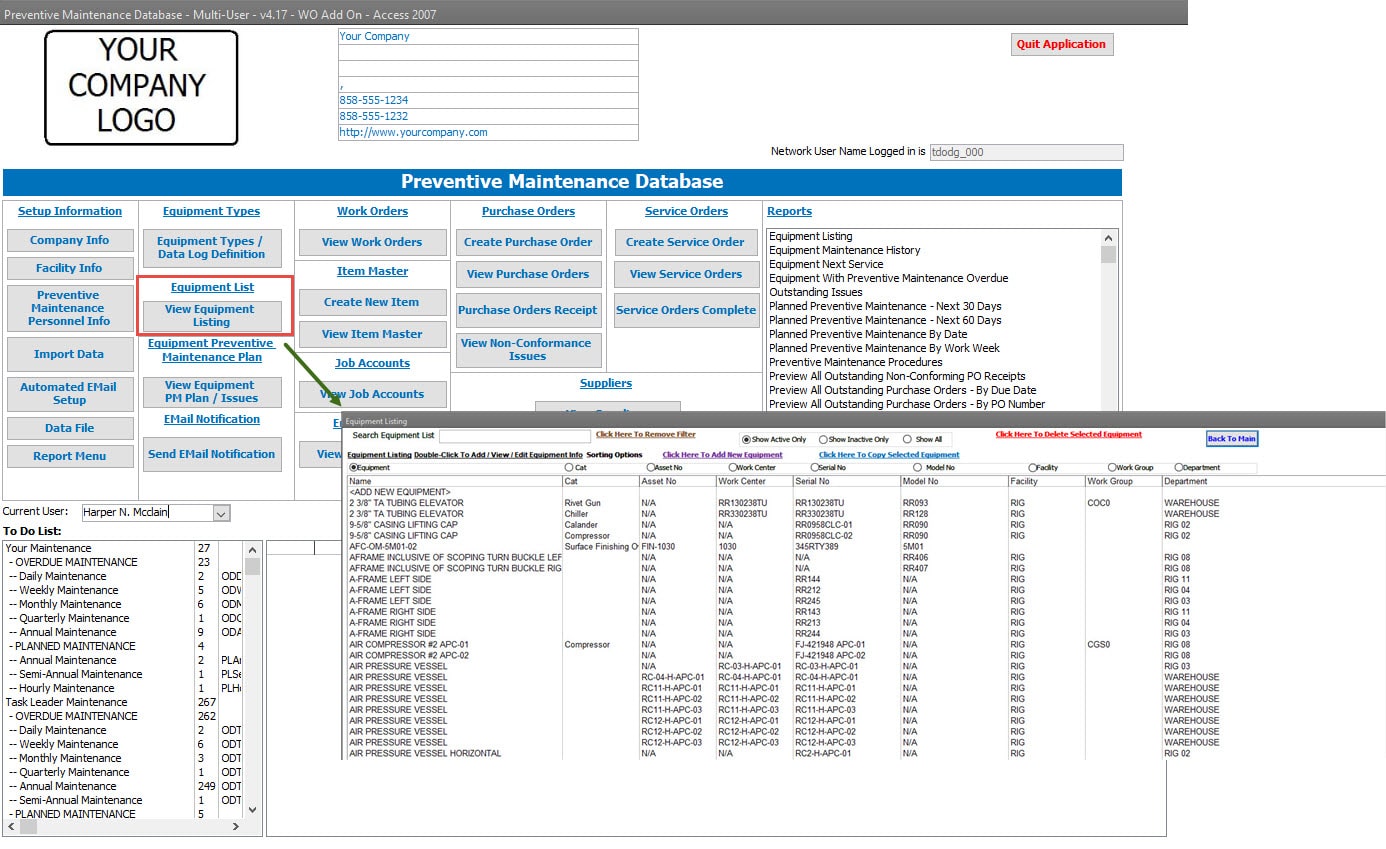

| Asset and Equipment Listing

Easily Search for Assets / Equipment by using the search field. Search by equipment names, serial numbers, model numbers, or any other information that defines the Asset / Equipment. Adding a new asset or equipment is as simple as one click. Assets with many similarities to an existing asset can be copied, only changing the necessary information, thus eliminating unnecessary data entry. |

|

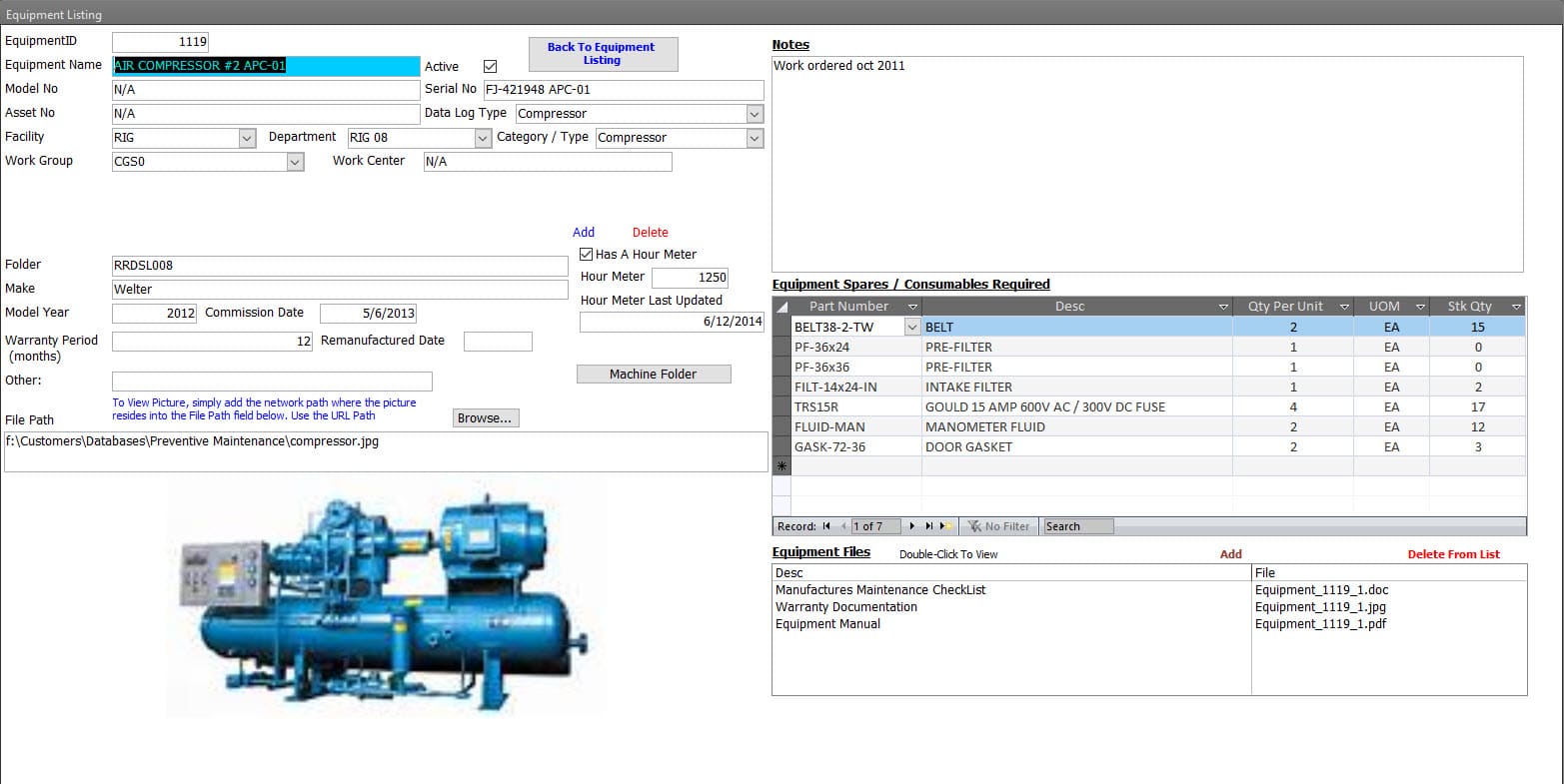

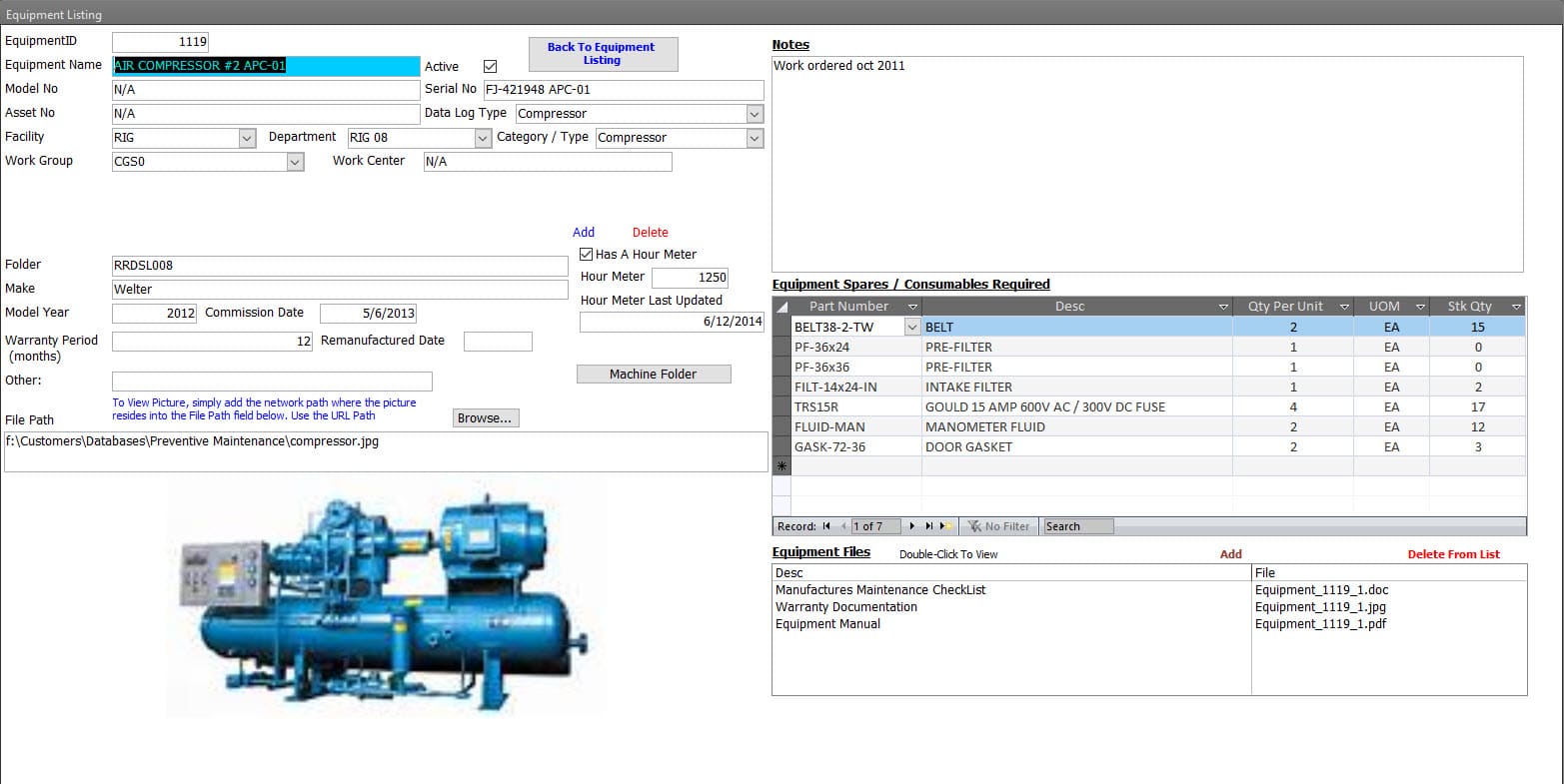

| Asset and Equipment Information

Each asset/equipment is identified in this preventive maintenance software using standard fields such as Asset/equipment name, model number, and serial number. In addition, the facility, department, work center, and workgroup can be added. |

|

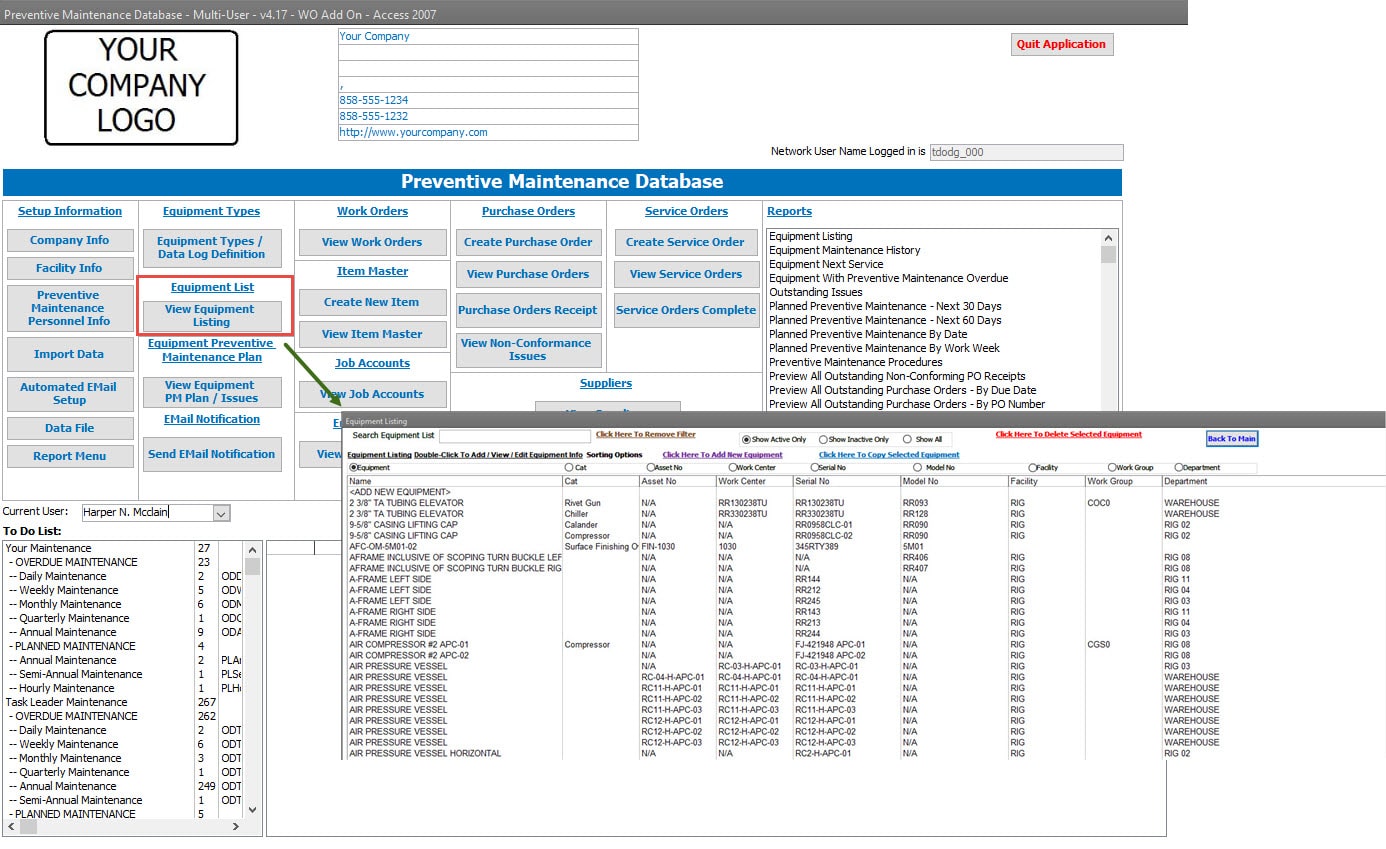

Asset and Equipment Listing

Easily Search for Assets / Equipment by using the search field.

Search by equipment names, serial numbers, model numbers, or any other information that defines the Asset / Equipment.

Adding a new asset or equipment is as simple as one click.

Assets with many similarities to an existing asset can be copied, only changing the necessary information, thus eliminating unnecessary data entry.

Asset and Equipment Information

Each asset/equipment is identified in this preventive maintenance software using standard fields such as Asset/equipment name, model number, and serial number. In addition, the facility, department, work center, and workgroup can be added.

The Category / Type field is the connection to a data log table definition should this asset require data logging.

A picture of the asset can be added.

A section in the asset record includes a list of spare parts and commodities consumed by the preventive maintenance tasks of this asset.

An unlimited number of files can be linked to each asset/equipment. Typical use of this area is to link User Manuals; Manufacturer’s recommended Preventive Maintenance schedule, Warranty Information, Purchase Orders, and Packing Lists.

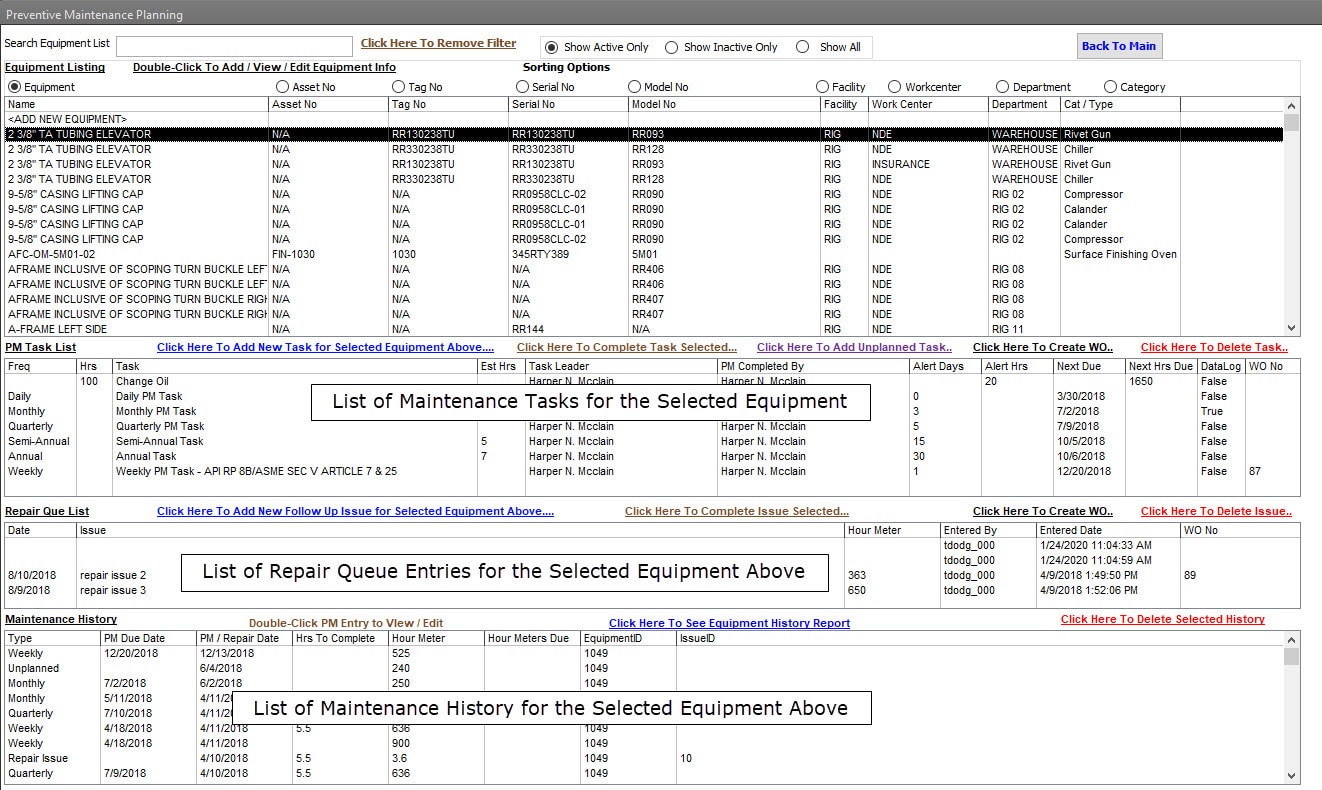

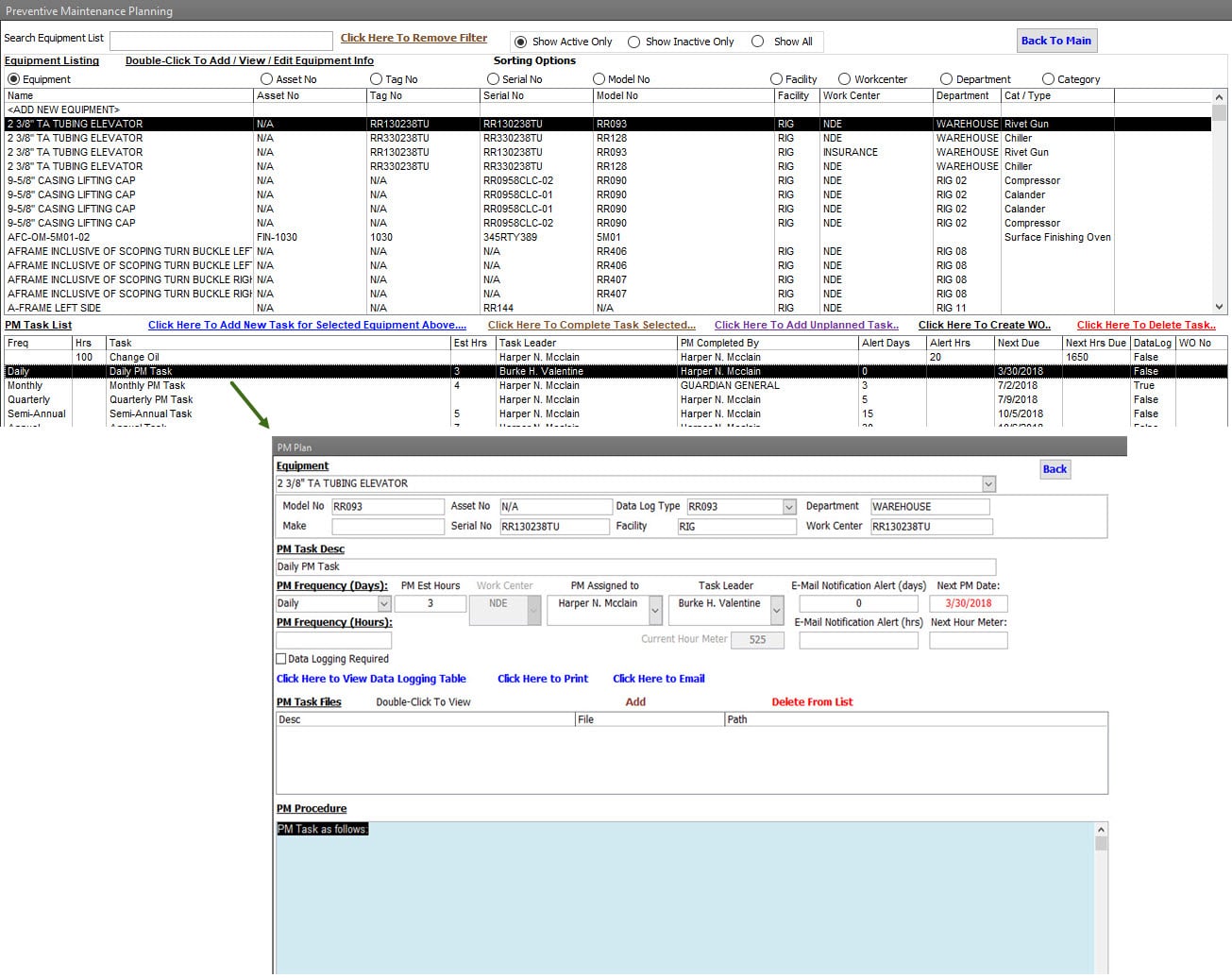

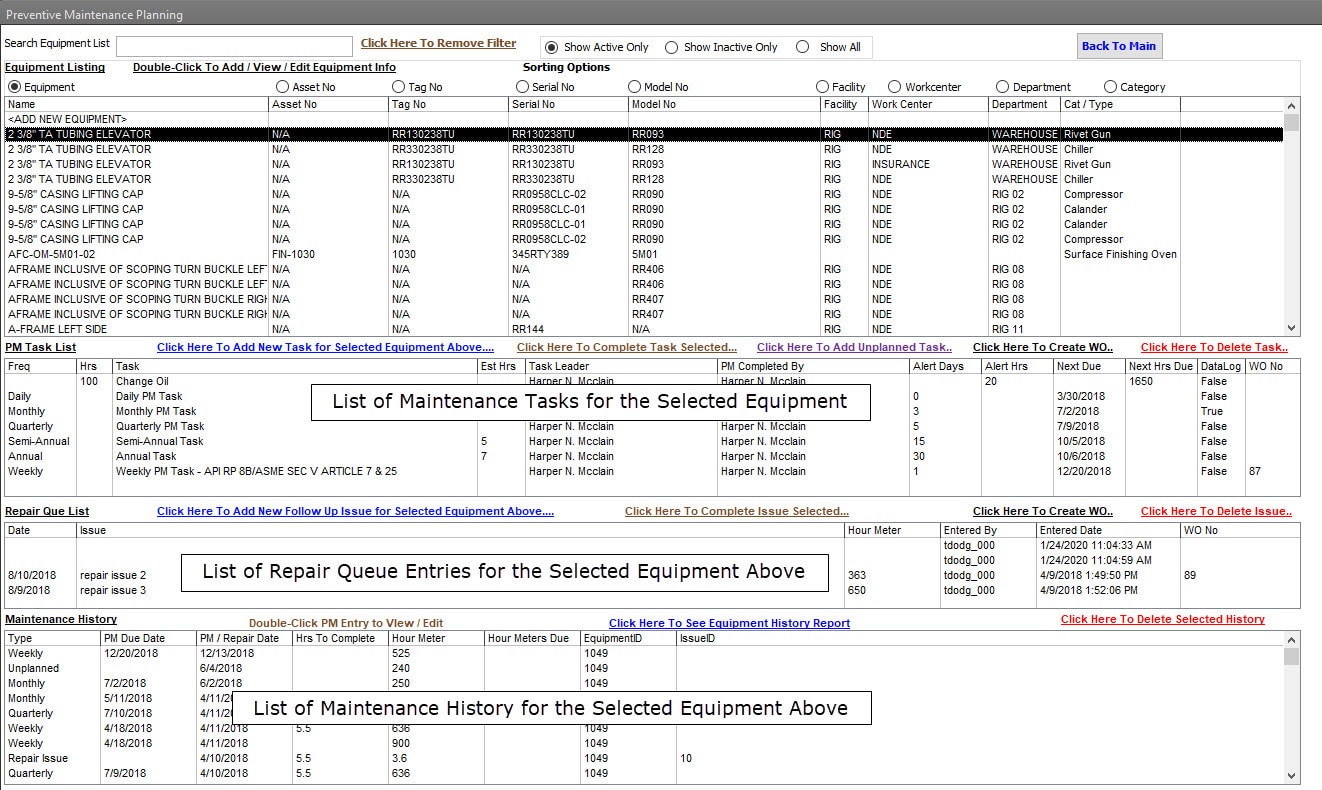

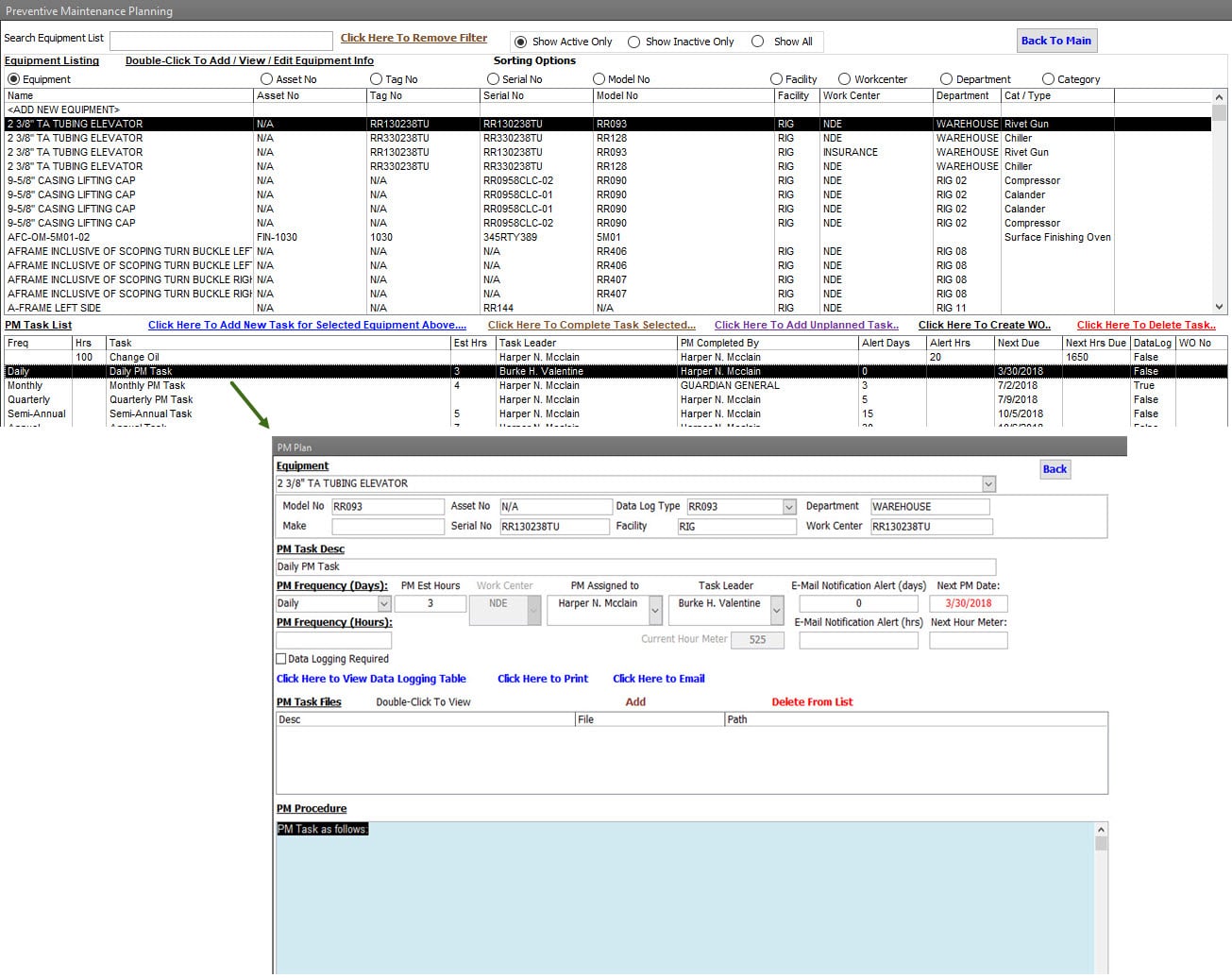

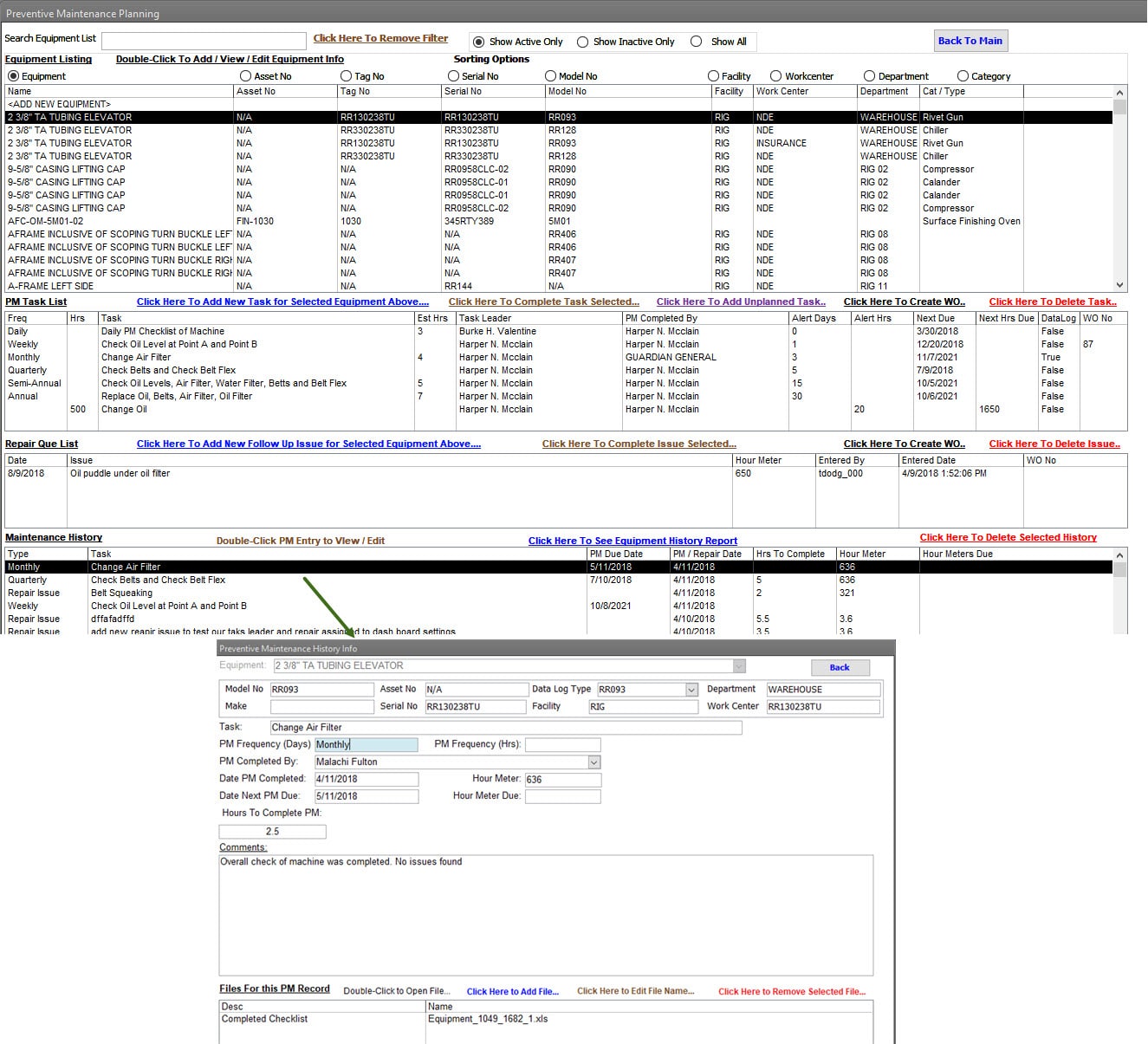

| Preventive Maintenance Plan

The Preventive Maintenance Plan section defines all Preventive Maintenance tasks for a specific asset/equipment and the frequency with those tasks need to be performed. |

|

| Preventive Maintenance Plan View

The Maintenance Plan View is used to view the Preventive Maintenance task, the current repair queue, and the maintenance history for each asset/equipment. |

|

| Preventive Maintenance Task List

Each Preventive Maintenance task needs to be defined. A Task Name, Description of the task, how often the task needs to be performed (frequency) in either days or machine hours, and the estimated hours needed to complete the task. |

|

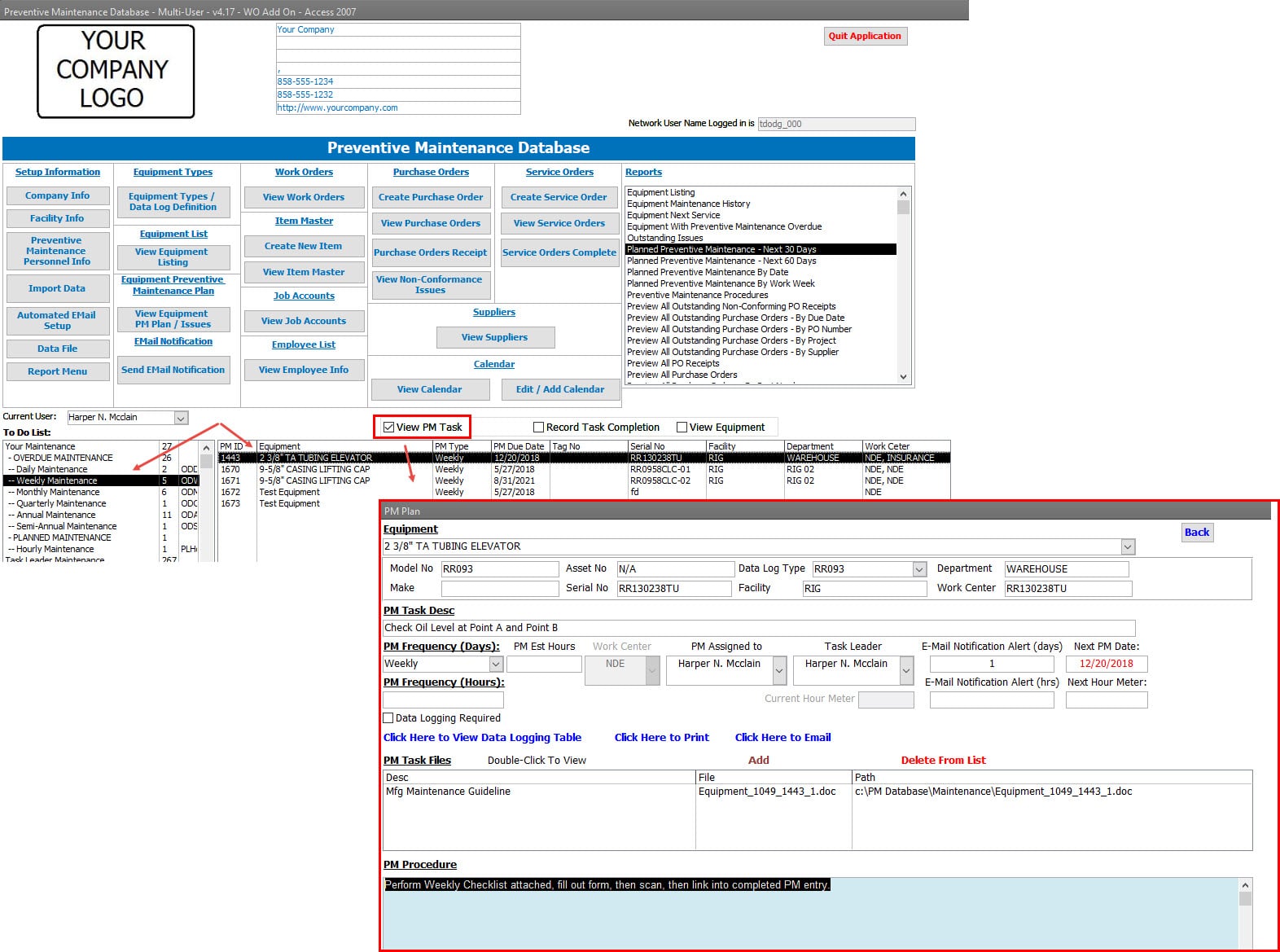

Preventive Maintenance Plan

The Preventive Maintenance Plan section defines all Preventive Maintenance tasks for a specific asset/equipment and the frequency with those tasks need to be performed.

Preventive Maintenance Plan View

The Maintenance Plan View is used to view the Preventive Maintenance task, the current repair queue, and the maintenance history for each asset/equipment.

Preventive Maintenance Task List

Each Preventive Maintenance task needs to be defined. A Task Name, Description of the task, how often the task needs to be performed (frequency) in either days or machine hours, and the estimated hours needed to complete the task.

The task is assigned to a specific party, and another party is considered the backup or team leader. The automated email function emails these two parties about upcoming preventive maintenance.

The Email Notification Alert is the days before the task becomes due, and the two parties begin to be notified of the upcoming preventive maintenance requirement.

If the task is to record the equipment’s readings, and the data log table is required, the task is marked as data logging required.

An unlimited number of files can be added to the task. For cases when organizations have procedures already in place for the task defined, that procedure can be added as a file. Then, when the task becomes due, the procedure can be printed out and referenced while performing the PM.

The PM procedure section can be used as the instructions for completing the PM.

Get started

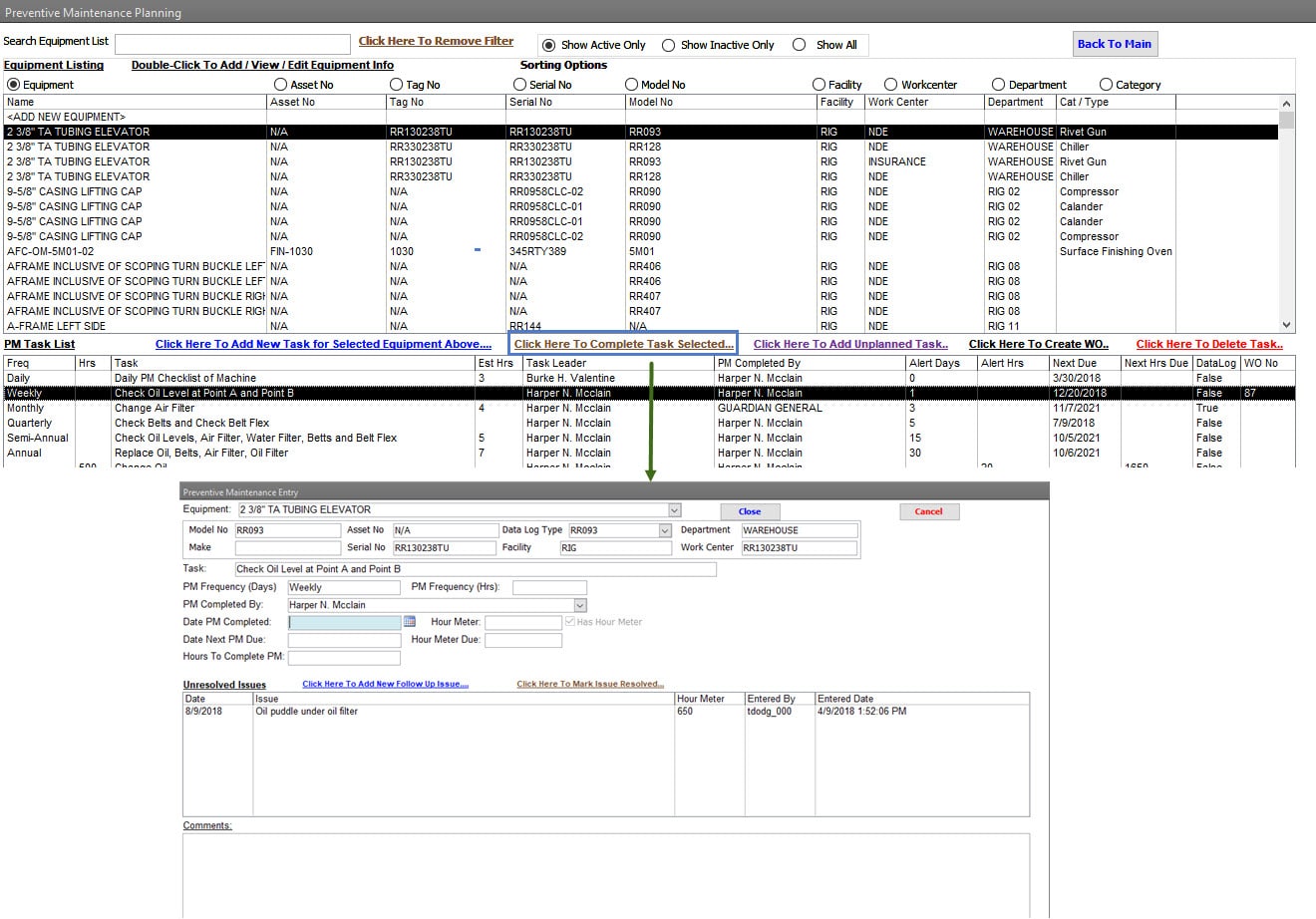

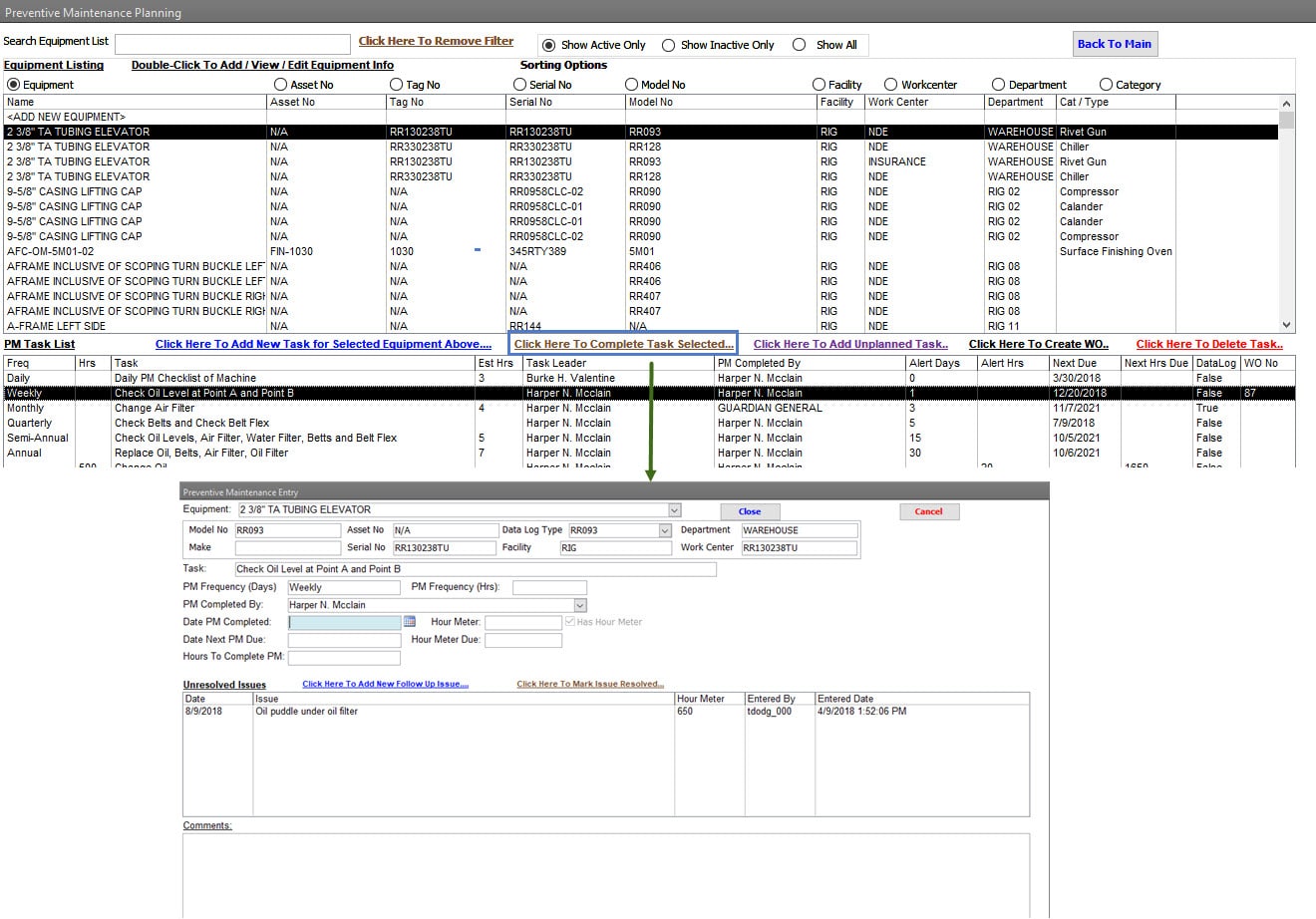

| Preventive Maintenance Completion

The completion of a planned maintenance task can be recorded by selecting the equipment, selecting the preventive maintenance task completed, and clicking a complete task. |

|

Preventive Maintenance Completion

The completion of a planned maintenance task can be recorded by selecting the equipment, selecting the preventive maintenance task completed, and clicking a complete task.

Minimal entries include entering the task that was completed and who completed the task. The next due date of the preventive maintenance is automatically based on the Frequency of the task and the completion date.

The time it took to complete the task can be entered, as well as any comments. In addition, an unlimited number of files can be added to the task completion record. Some typical uses are a filled-out checklist, third-party maintenance summary, inventory list of consumables used, or packing list of consumables purchased.

| Repair Queue

The repair queue is used when somebody recognizes an issue with an asset/equipment like “machine down,” leaking oil, “making weird noises,” or fan belt squeaking; they can enter a repair request. |

|

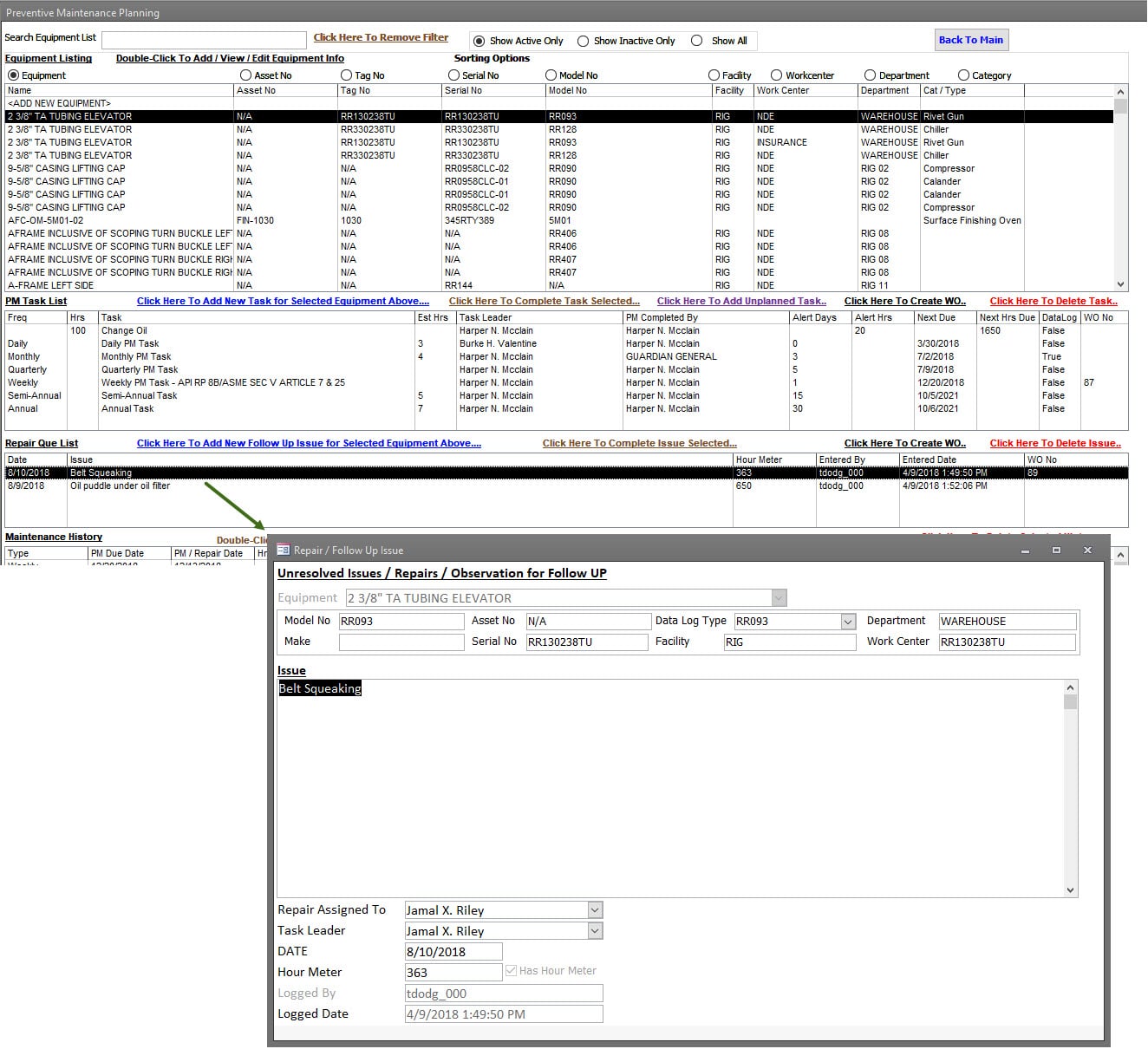

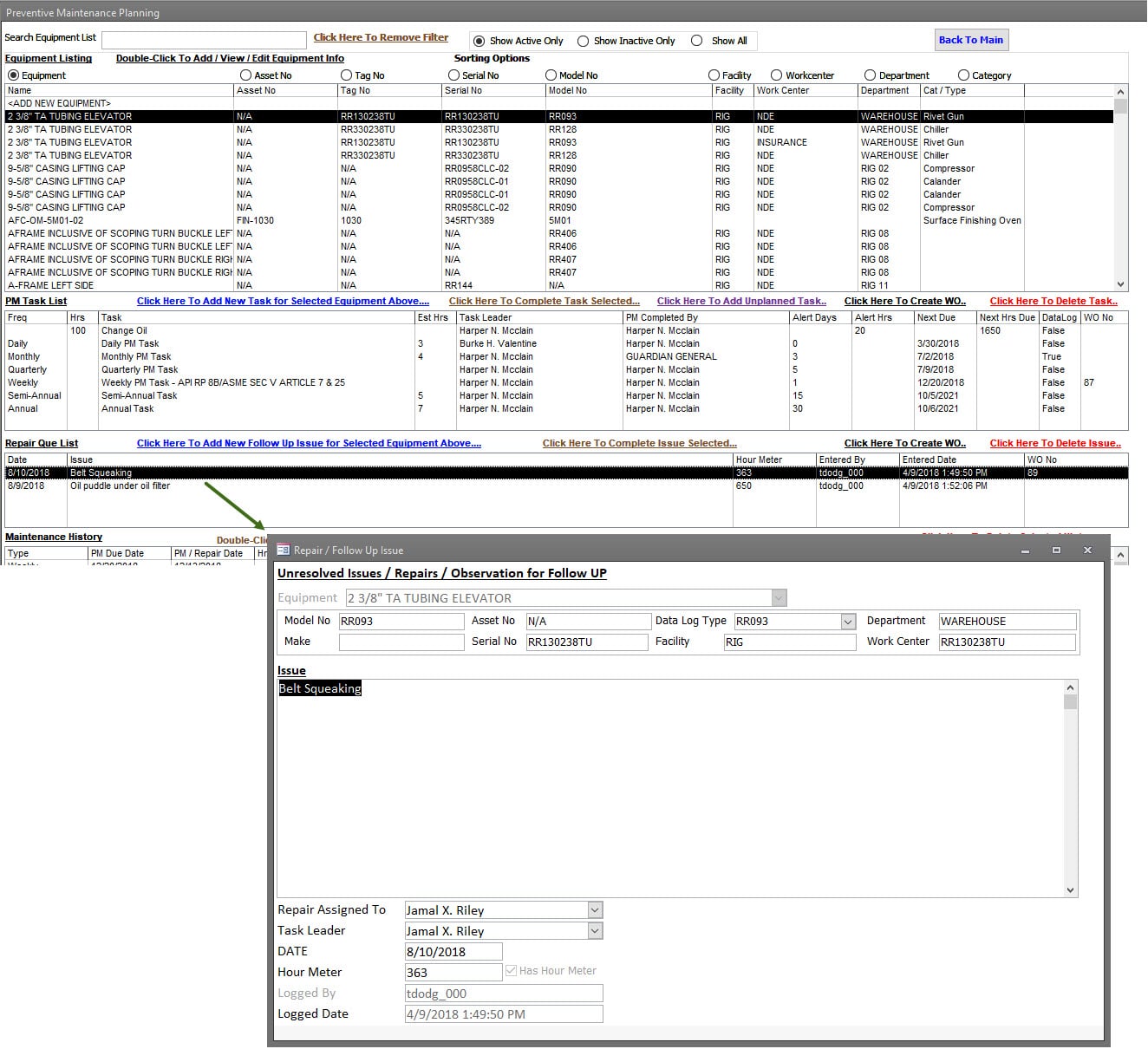

Repair Queue

The repair queue is used when somebody recognizes an issue with an asset/equipment like “machine down,” leaking oil, “making weird noises,” or fan belt squeaking; they can enter a repair request.

This repair request is entered for specific assets/equipment with the issue noted.

The repair issue should be assigned to two parties—the date the repair was created and the operator entering the request is automatically added.

These repair requests are included in the automated emails and can be emailed when the request is entered.

When repairs are needed immediately, like in “machine down” situations, an Unplanned Preventive Maintenance entry is created.

This is used to determine the unplanned downtimes for each machine.

|

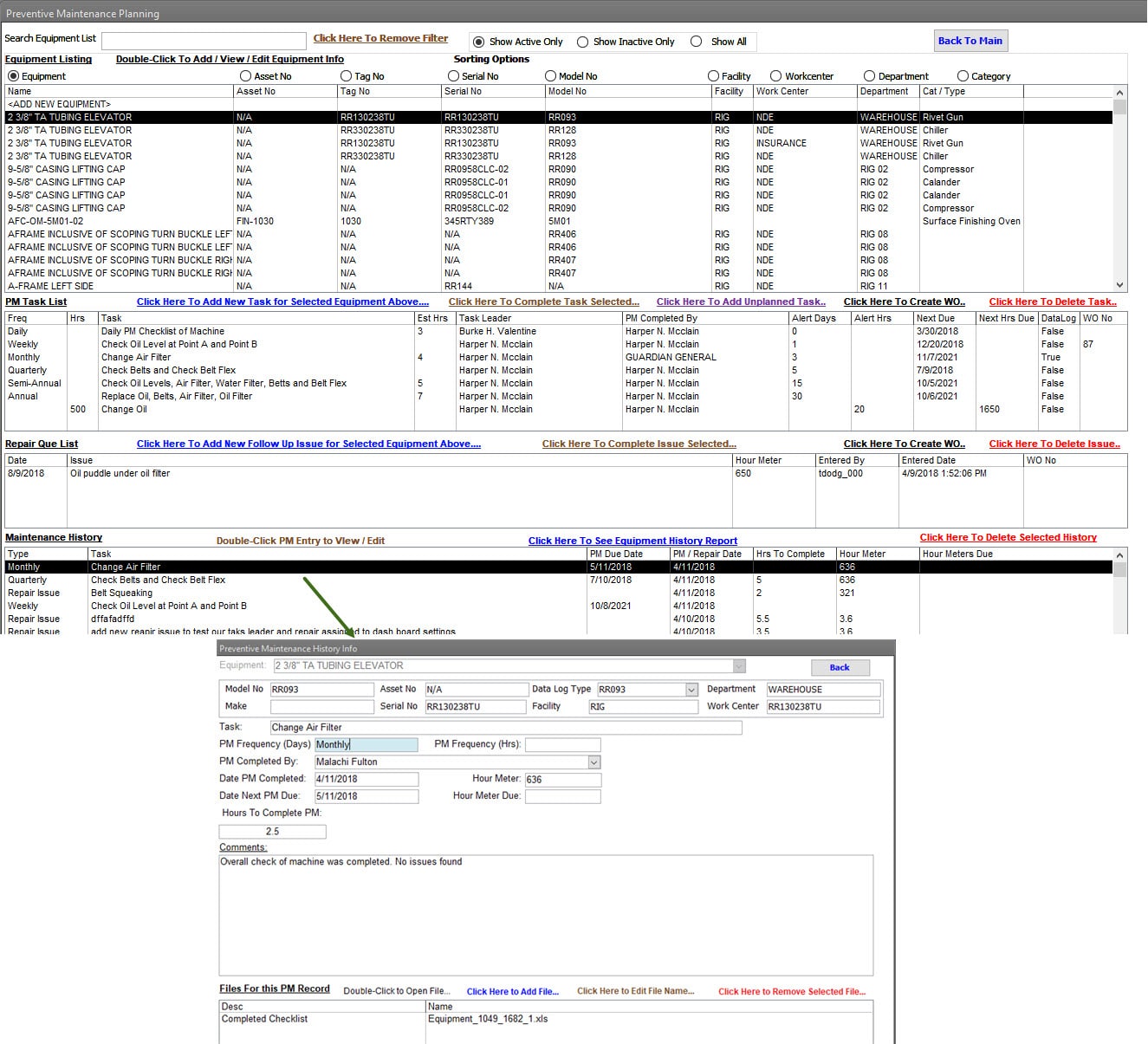

Preventive Maintenance History The Maintenance History can be viewed by selecting an asset/equipment to see all Maintenance Entries – Planned, Unplanned, or Repair Entries. |

|

Preventive Maintenance History

The Maintenance History can be viewed by selecting an asset/equipment to see all Maintenance Entries – Planned, Unplanned, or Repair Entries.

When a specific PM task is selected, the Maintenance History shows the PM task’s history and any Unplanned and Repair tasks.

Double-clicking on a maintenance history record shows the details of the preventive maintenance task completed. Details such as when the task was completed, who completed the task, and in the case of a planned PM task completed, the following preventive maintenance due date.

Labor times to complete the maintenance task can be entered, as well as any comments.

In addition, an unlimited number of files can be added to the maintenance task completion record. Some typical uses might include a completed checklist, third-party maintenance summary, inventory list of consumables used, or packing list of consumables purchased.

|

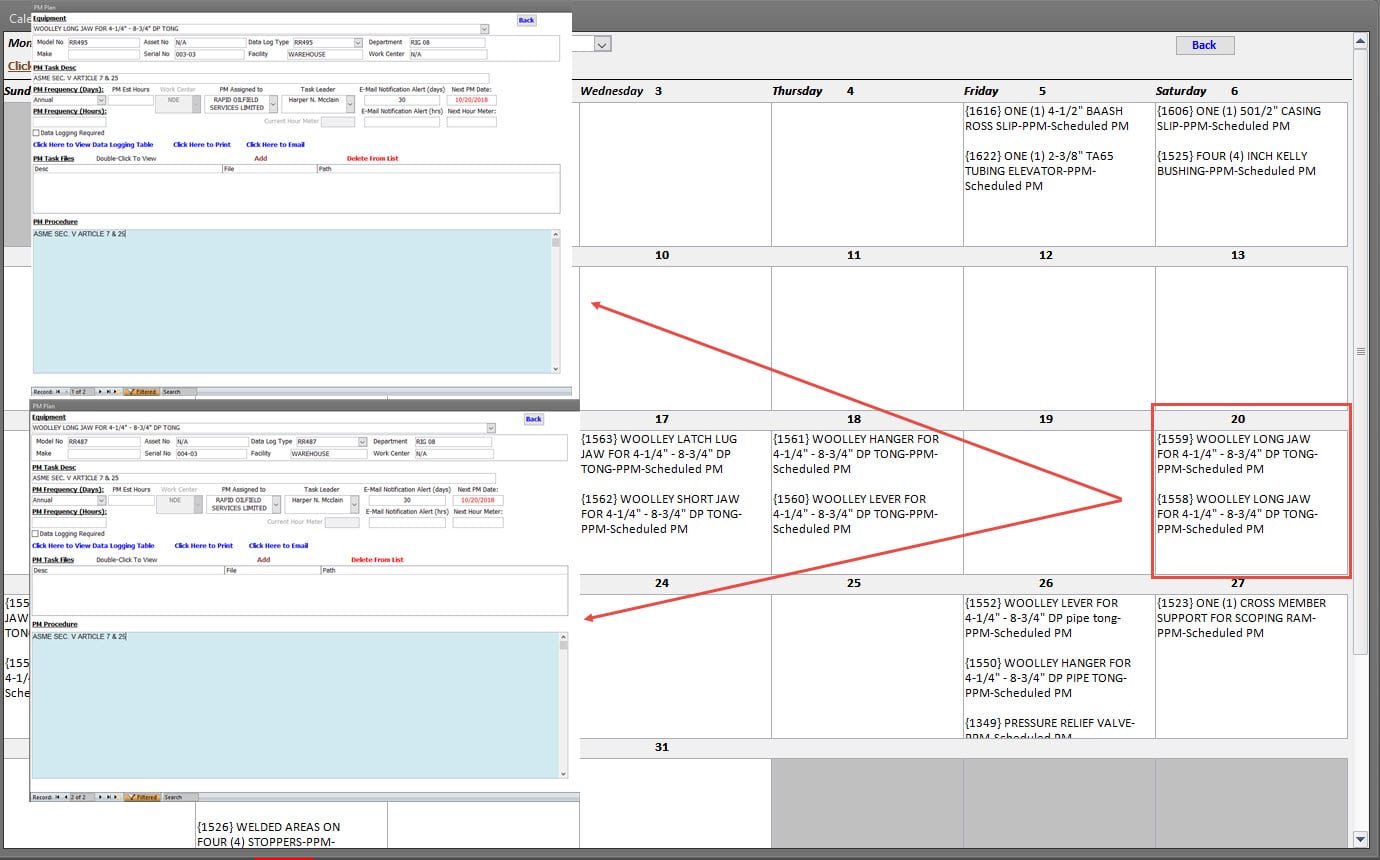

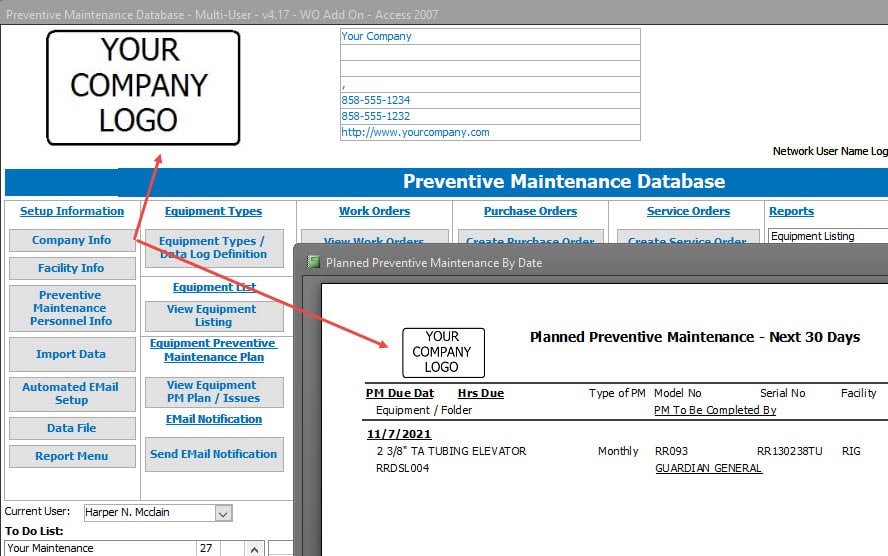

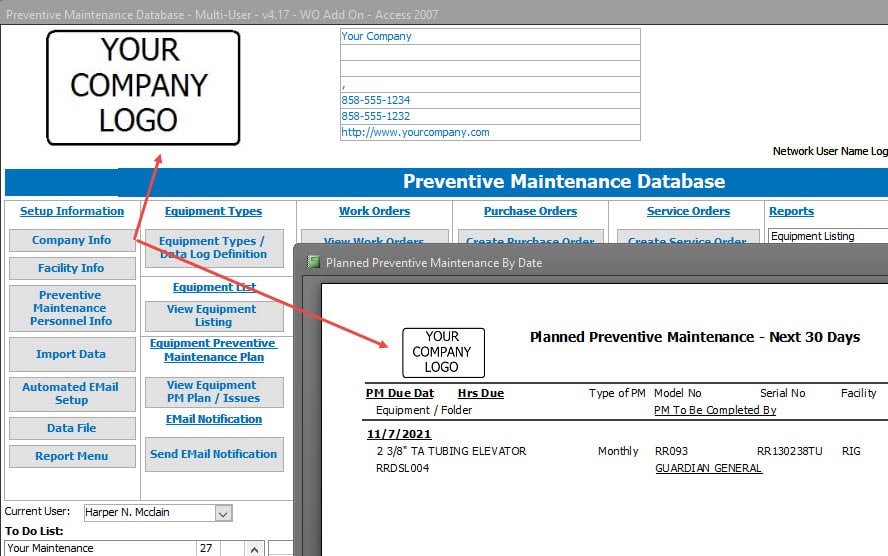

Calendar The calendar section displays the planned preventive maintenance in a monthly view. |

|

|

Daily Preventive Maintenance Task Details The calendar can be filtered by month and year. |

|

Calendar

The calendar section displays the planned preventive maintenance in a monthly view.

The calendar is updated automatically as new preventive maintenance tasks are added when the tasks are completed, and the following due dates are assigned.

Daily Preventive Maintenance Task Details

The calendar can be filtered by month and year.

Double-Click on any day and the Preventive Maintenance task(s) details are displayed.

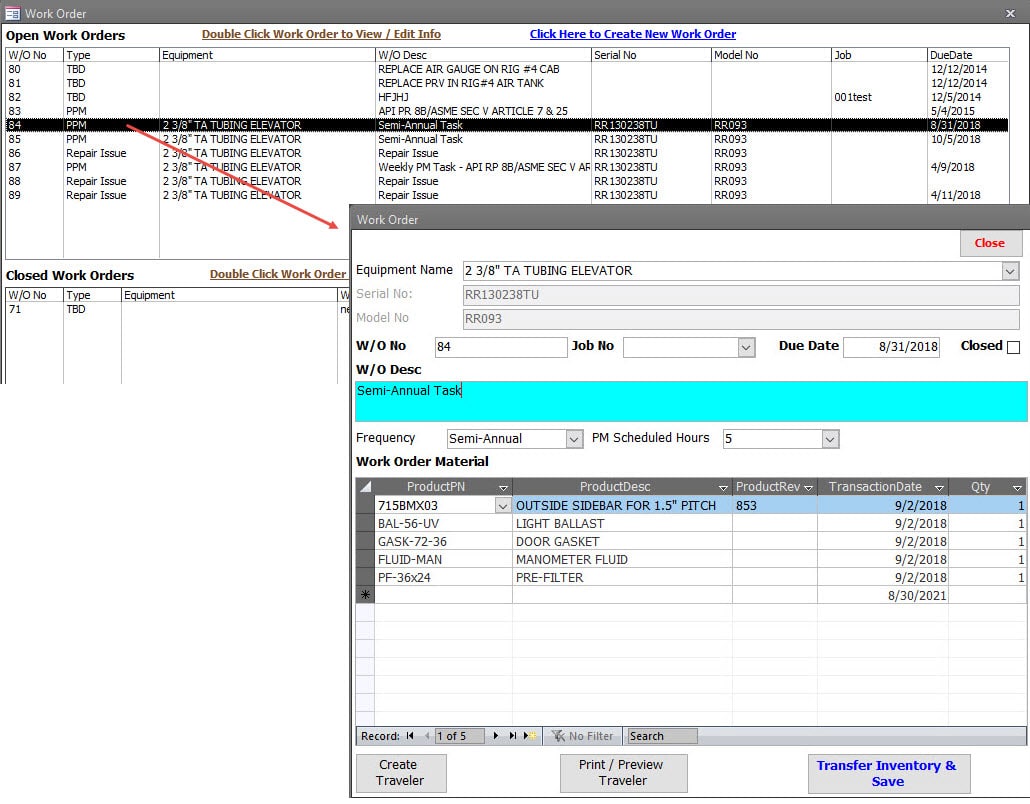

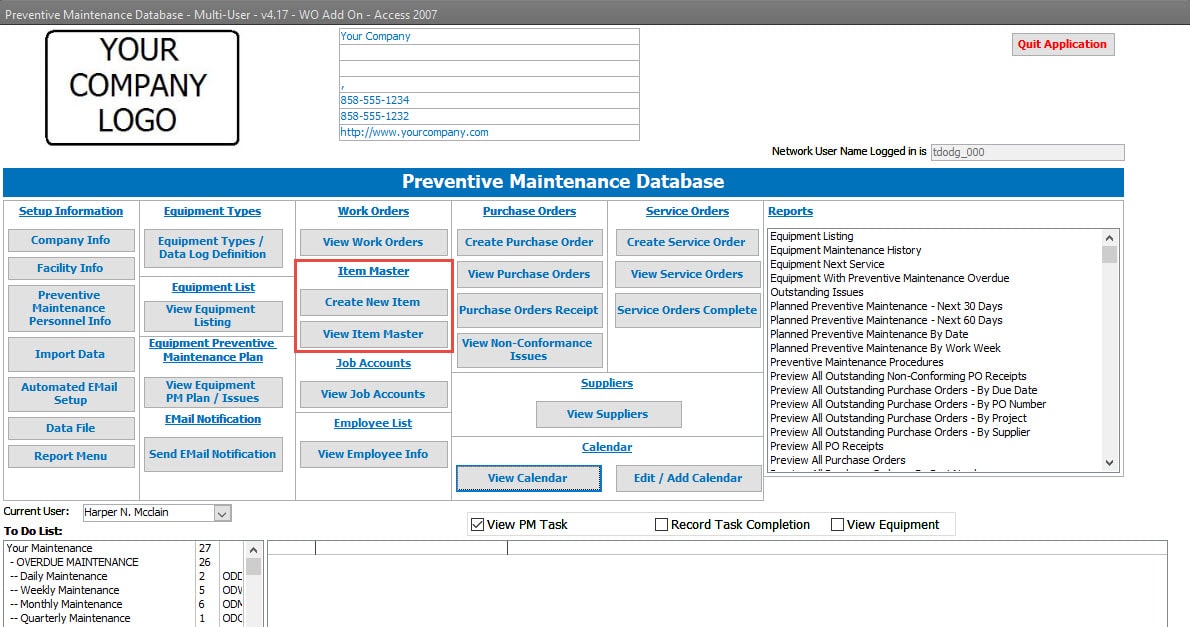

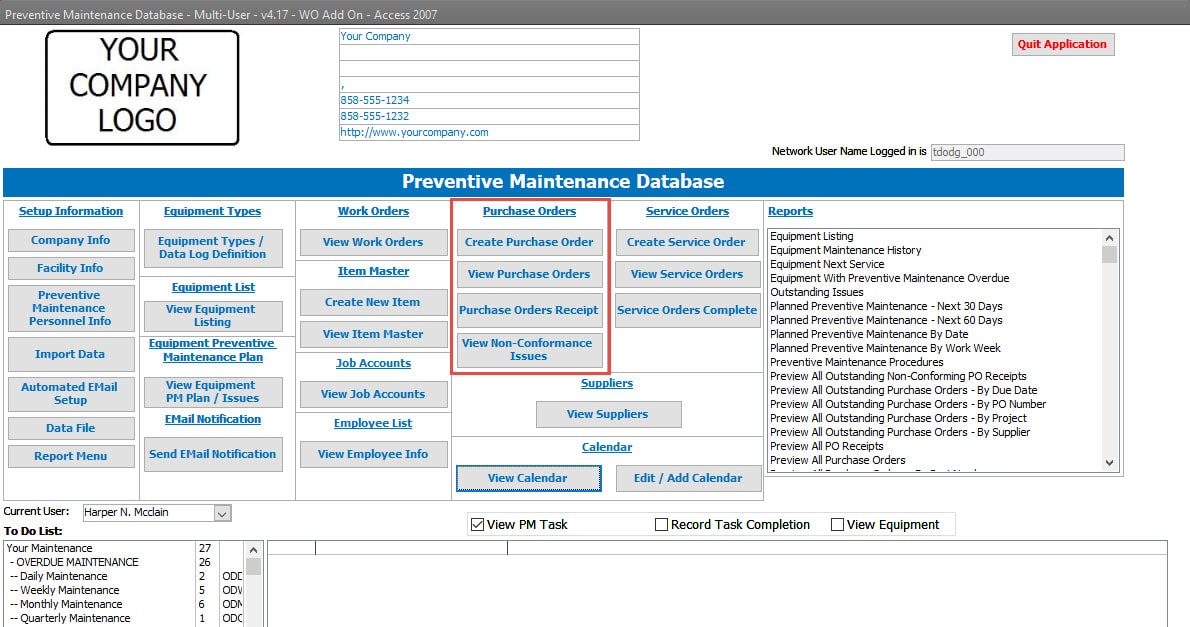

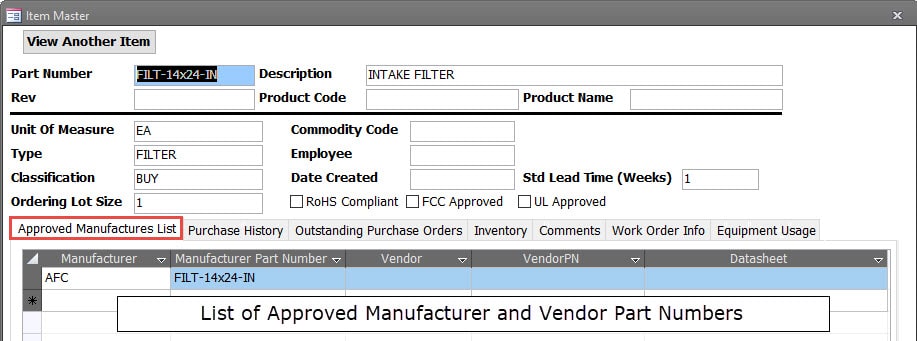

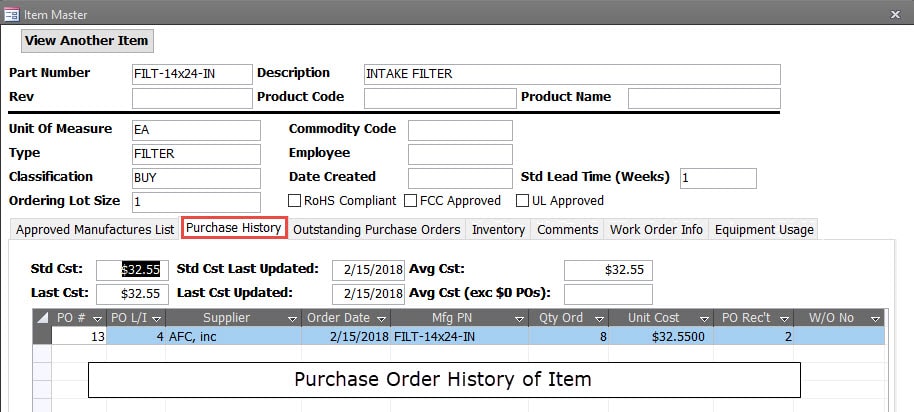

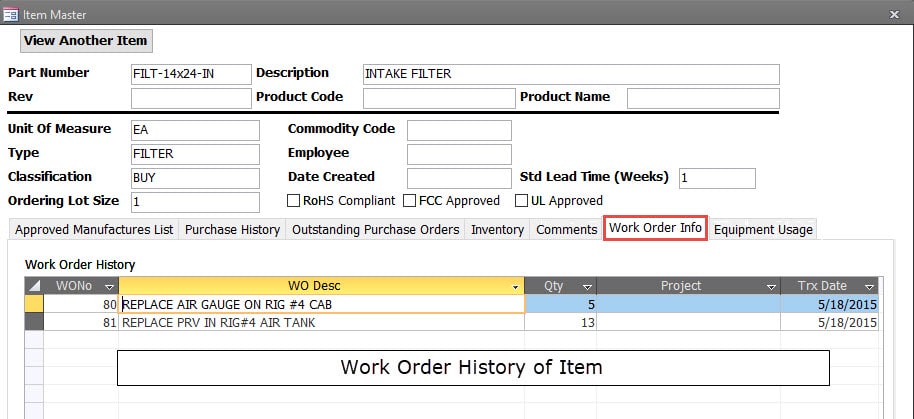

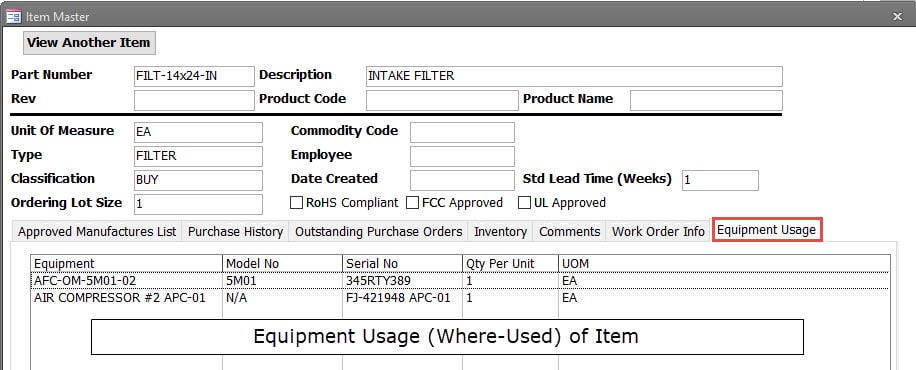

- Work Order Module

- Work Orders

- Item Master

- Part Library

- Approved Manufactures List

- Purchase History

- Outstanding Purchase Orders

- Part Inventory

- Work Order Information

- Equipment Usage

- Purchase Orders

- Purchase Order Listing

- Purchase Order Detail

- Suppliers

- Supplier Details

|

Work Order Module The optional Work Order Module for Preventive Maintenance software includes creating Work Orders. Also included is an Item Master, which is used to manage the inventory in support of the Preventive Maintenance program. This inventory includes consumables, spare parts, and other materials needed to support the program. A Purchase Order module is included to manage the purchasing and receipt of materials and goods. In addition, a purchase order receipt process ensures that the inventory quantities are accurate. |

|

|

Work Orders Work Orders are linked to a specific maintenance event, whether planned or unplanned. |

|

|

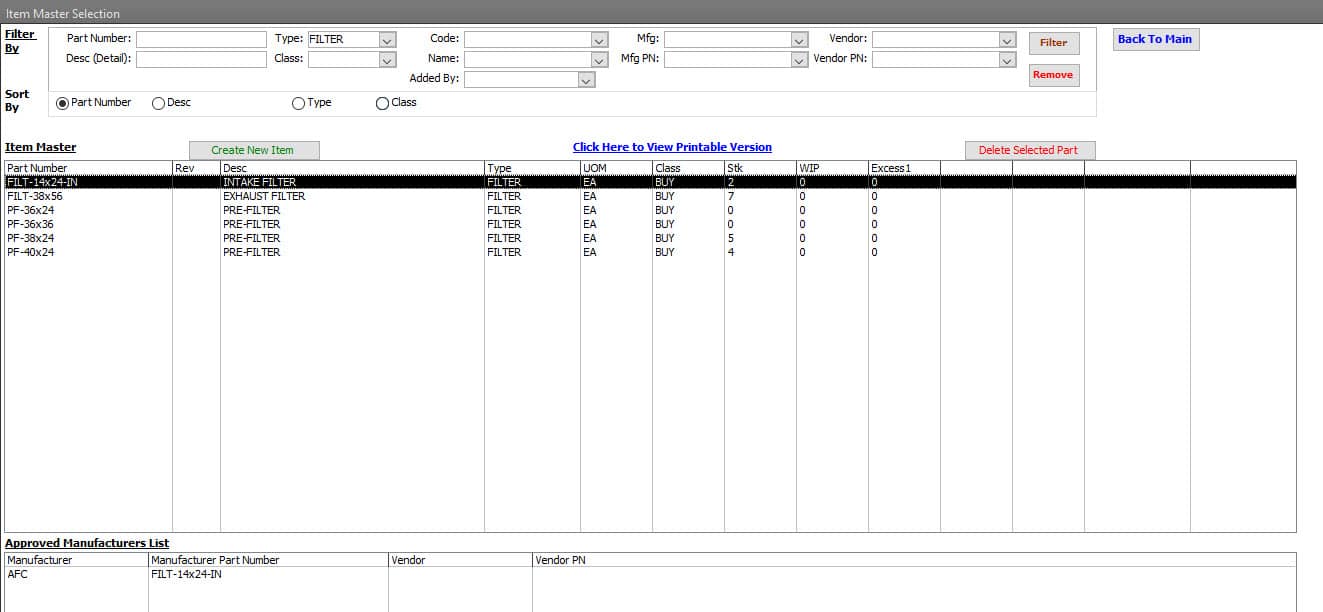

Item / Part / Material Master The Item Master section of the Work Order Module is used to create and manage all of the part libraries for all the materials, goods, and consumables used in support of the Preventive Maintenance program. |

|

|

Part Library / Listing Easily search part library using various fields and combinations of those fields. |

|

|

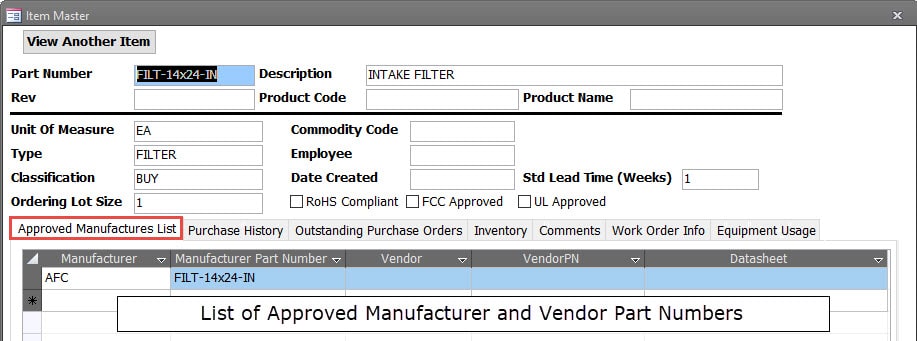

Part Approved Manufactures List Each Item can have an unlimited number of acceptable manufacturer and vendor part numbers. Additionally, each Supplier / Vendor may have their part numbers for the same part across the Supply Chain. |

|

|

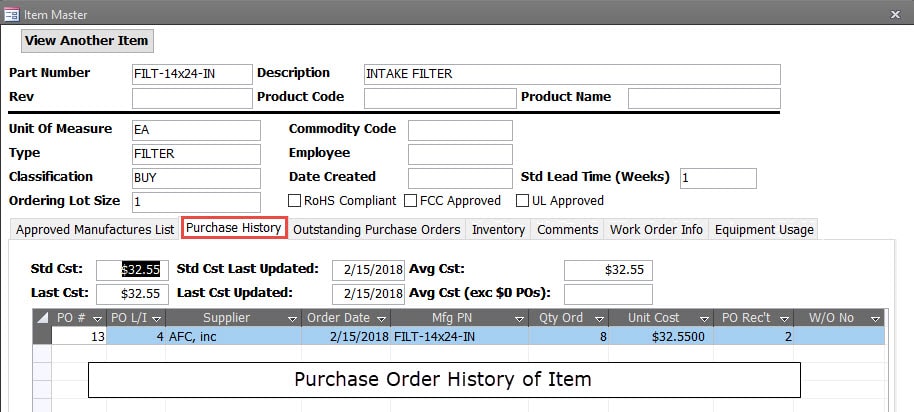

Part Purchase Order History Easily see all of the Purchase Order history of the part. |

|

|

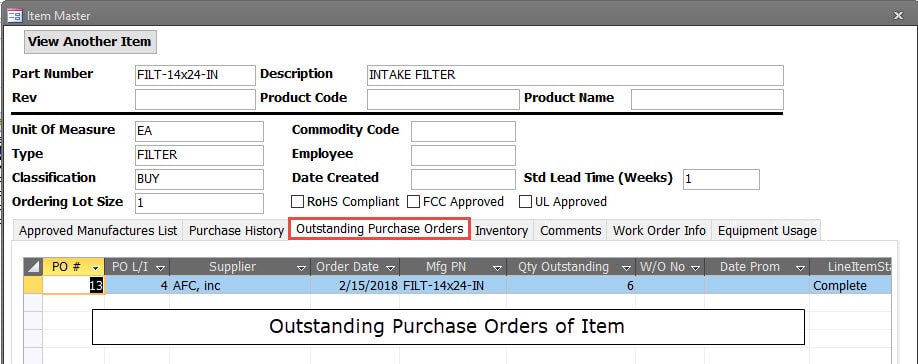

Part Outstanding Purchase Orders Easily View the Outstanding Purchase Orders for the part. |

|

|

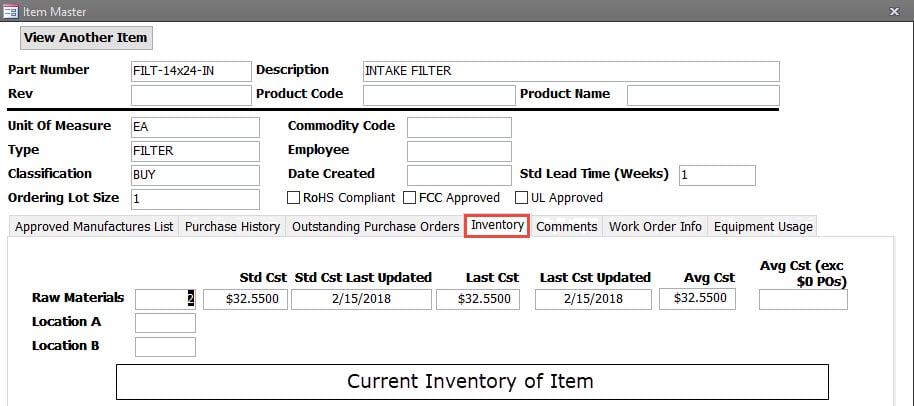

Part Inventory / Stock Levels View Inventory levels, Standard, Last and Average Costs. |

|

|

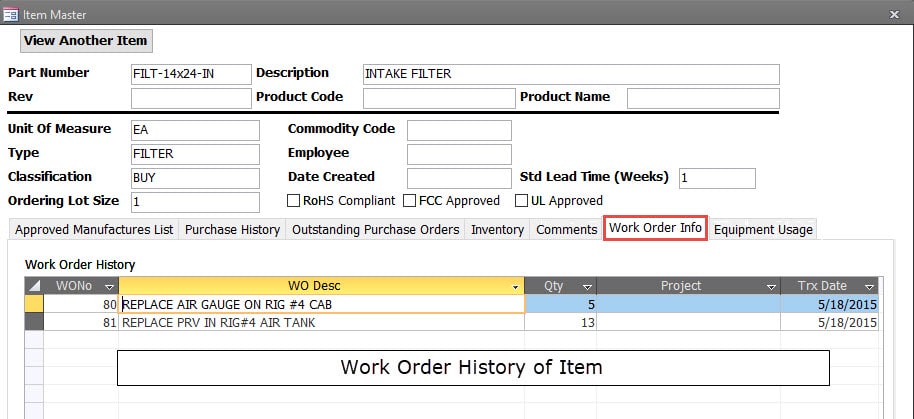

Part Work Order Information Easily View the Work Orders of the Part, the Work Order Information, and the Quantities consumed. |

|

|

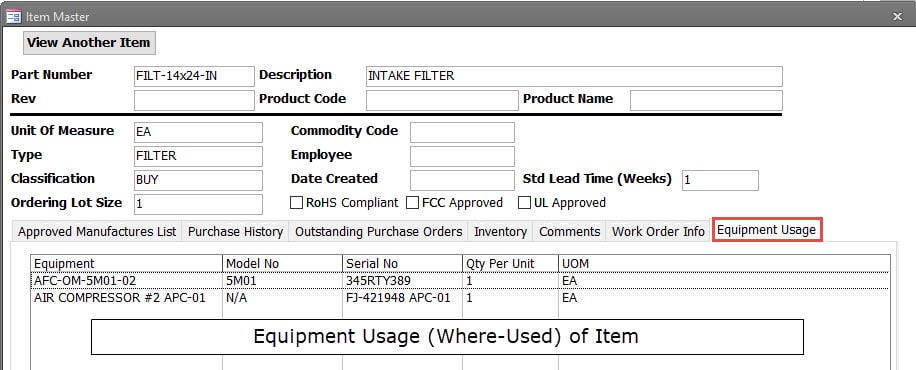

Part Where-Used / Equipment Usage View Where-Used for the Part. |

|

|

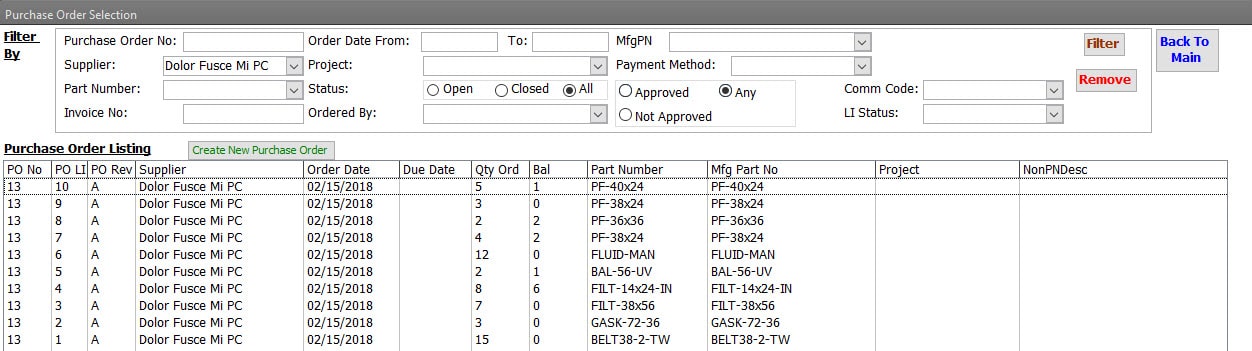

Purchase Orders The Purchase Order section of the Work Order Module is used to create and manage Purchase Orders. |

|

|

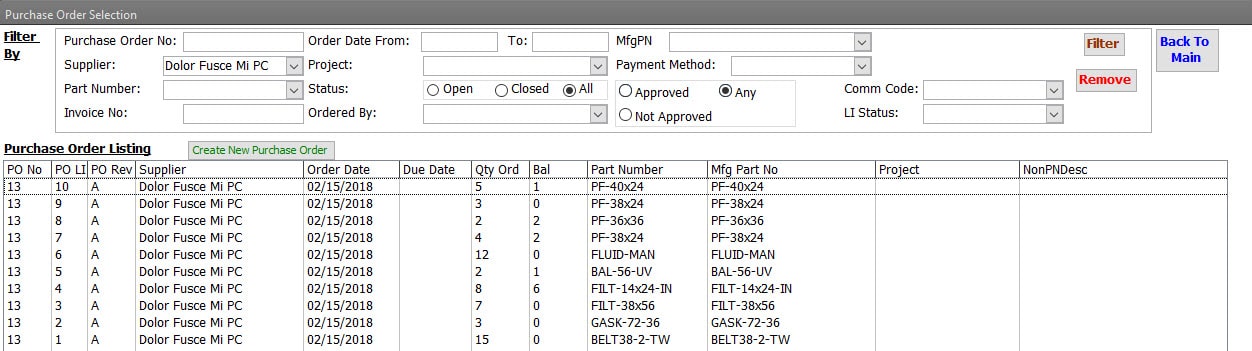

Purchase Order Listing Easily search and find Purchase Orders using various fields and combinations. |

|

|

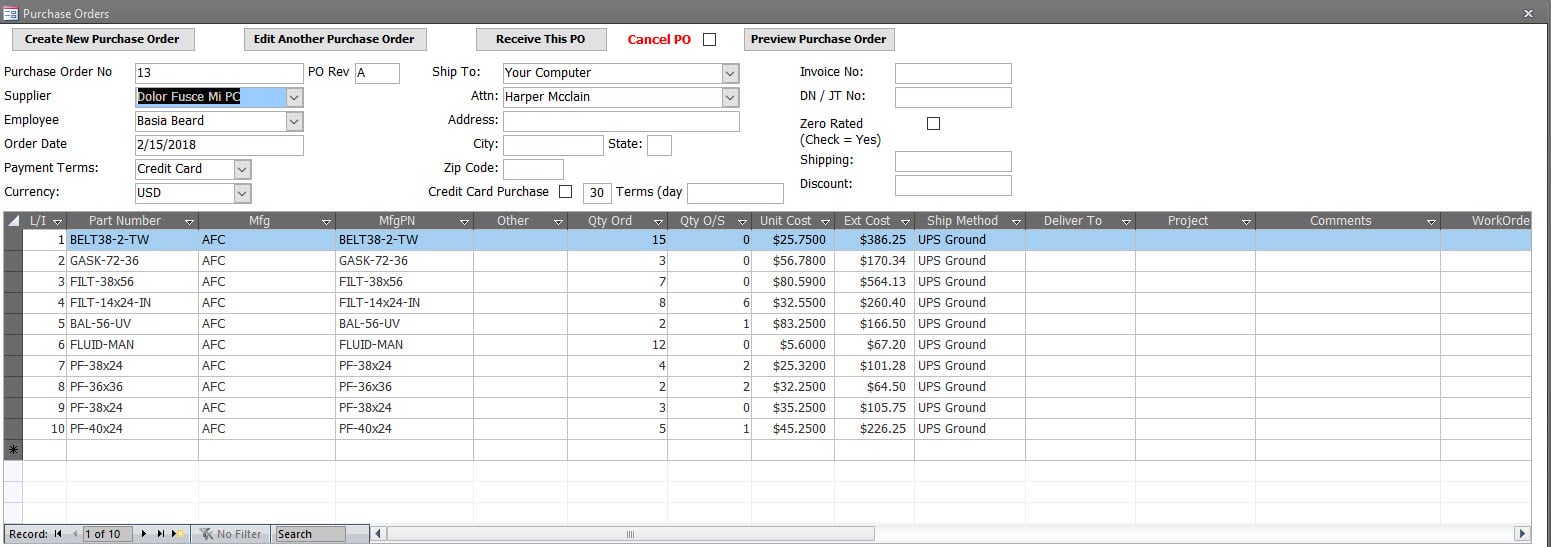

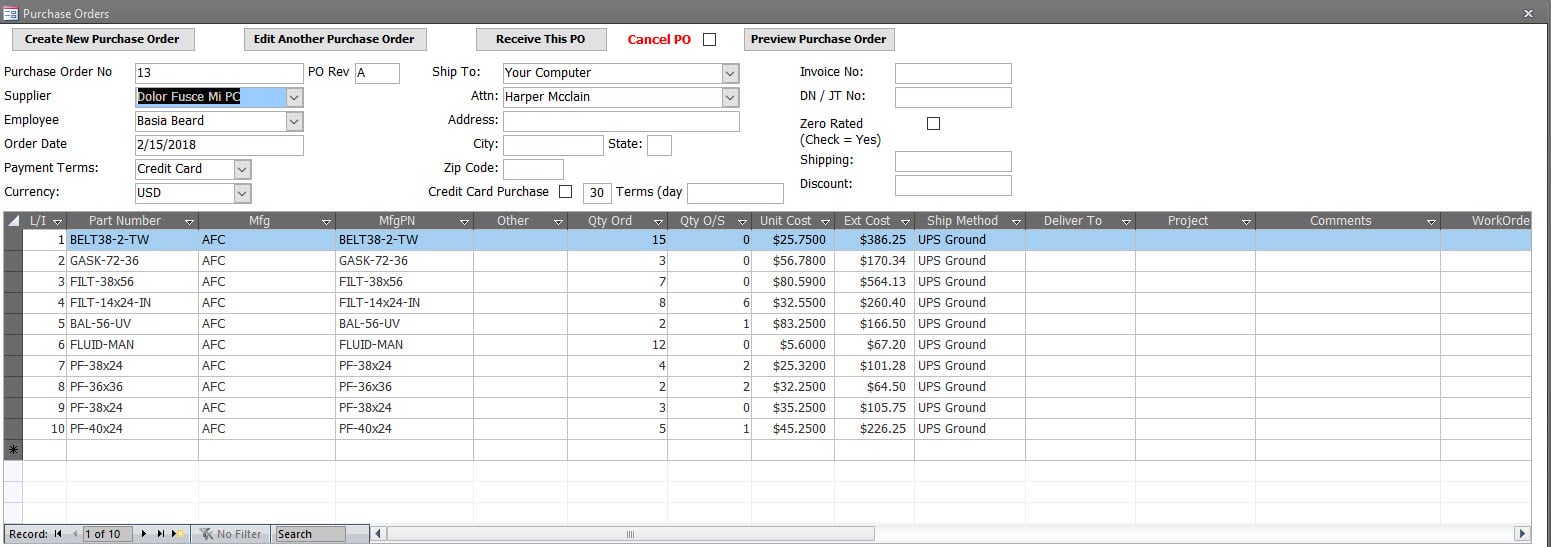

Purchase Order Information and Detail The Purchase Order contains basic information such as the Supplier / Vendor, Delivery Information, Part Numbers, Quantity, and Unit Costs. |

|

|

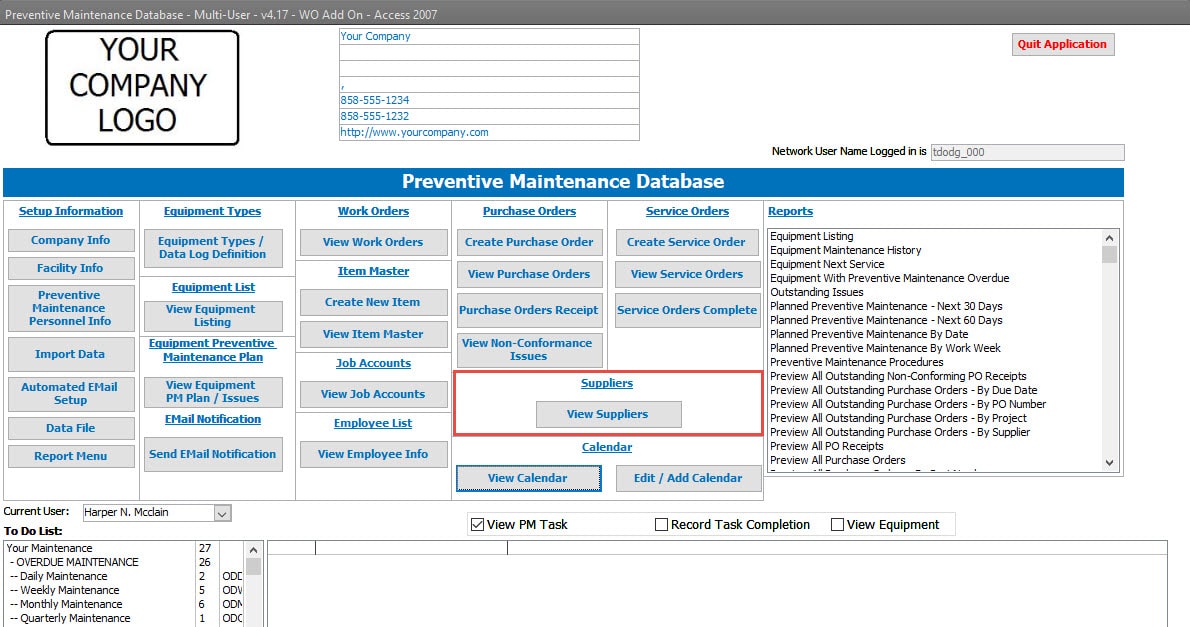

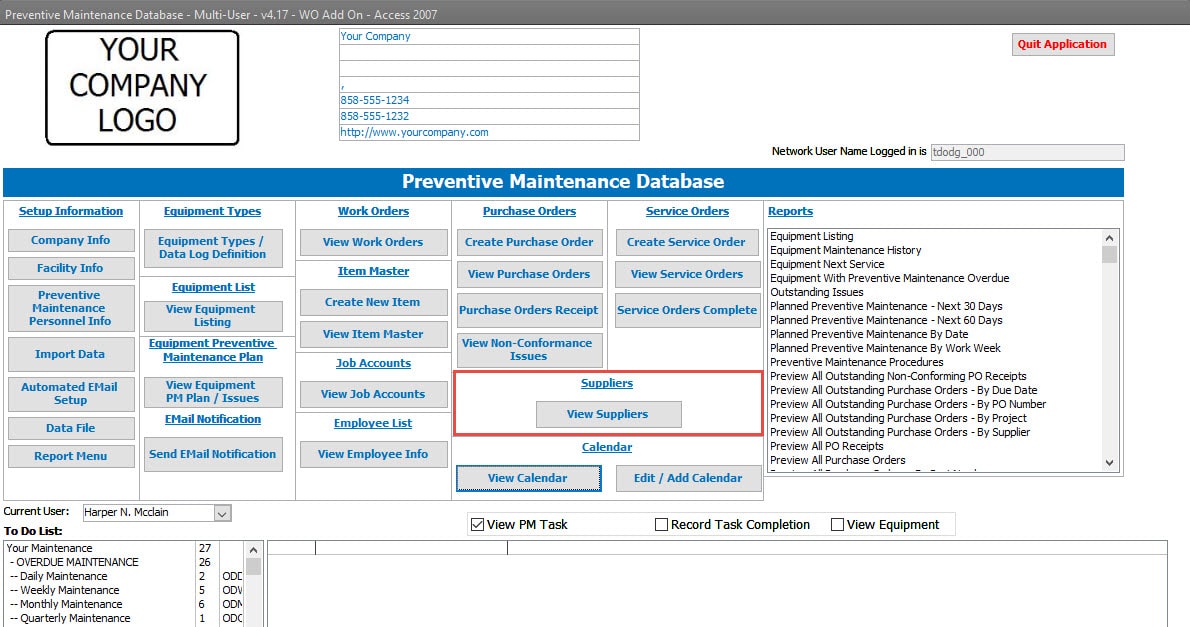

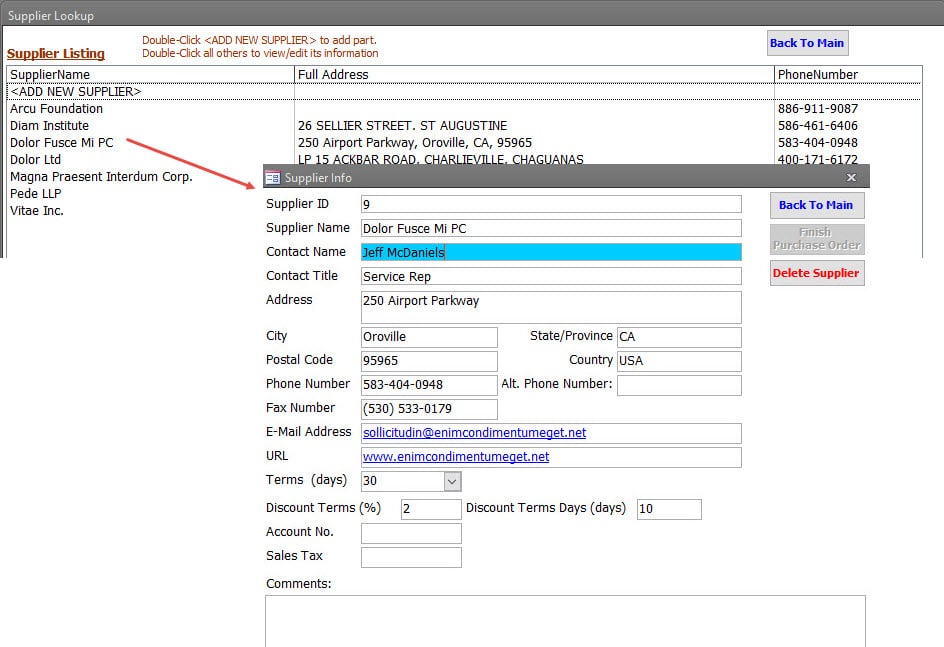

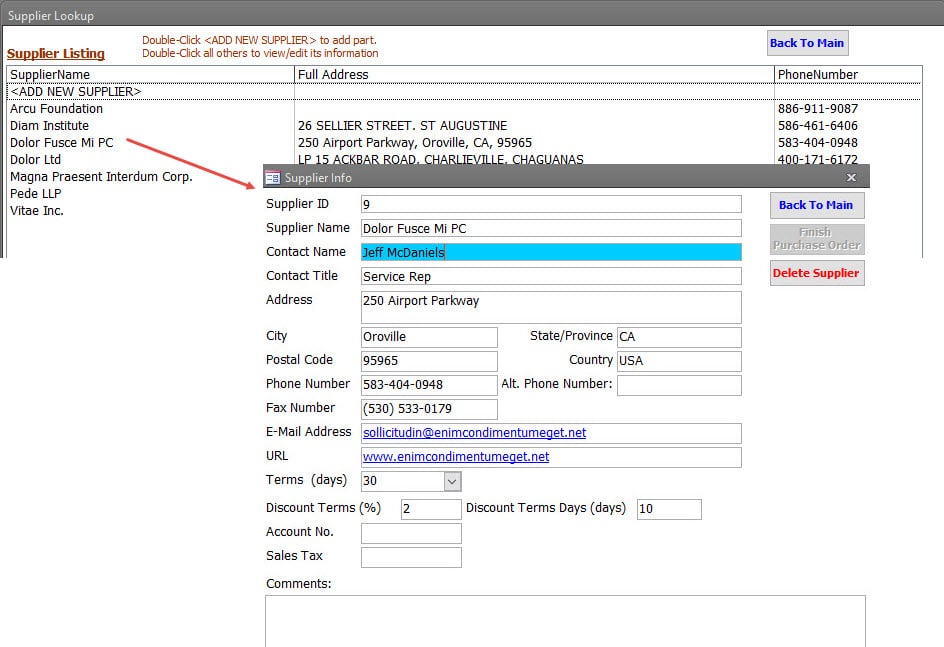

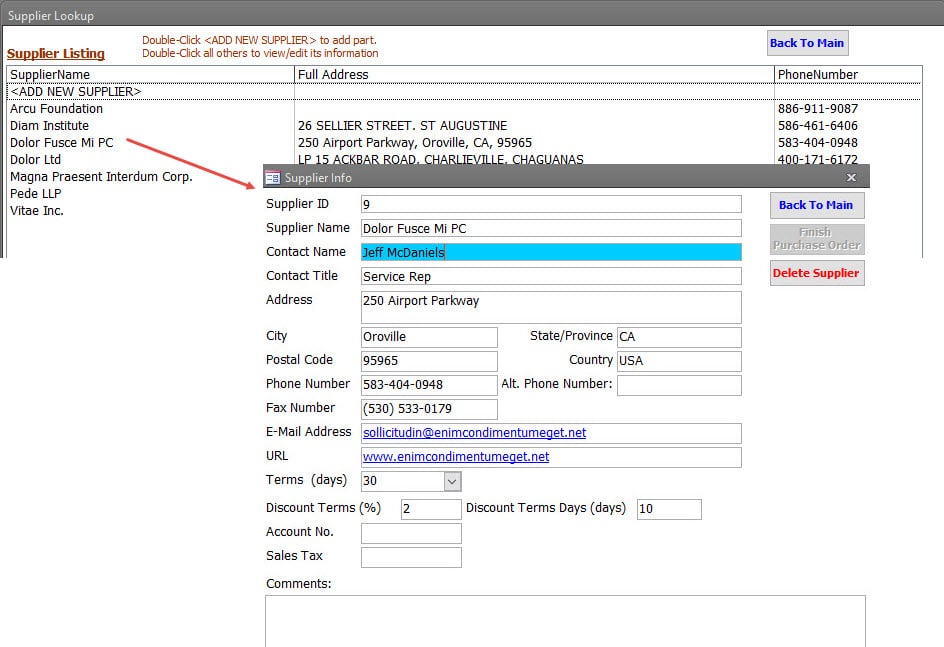

Suppliers The Supplier section of the Work Order Module is used to create and manage Suppliers in support of the Purchase Order and Service Order sections. |

|

|

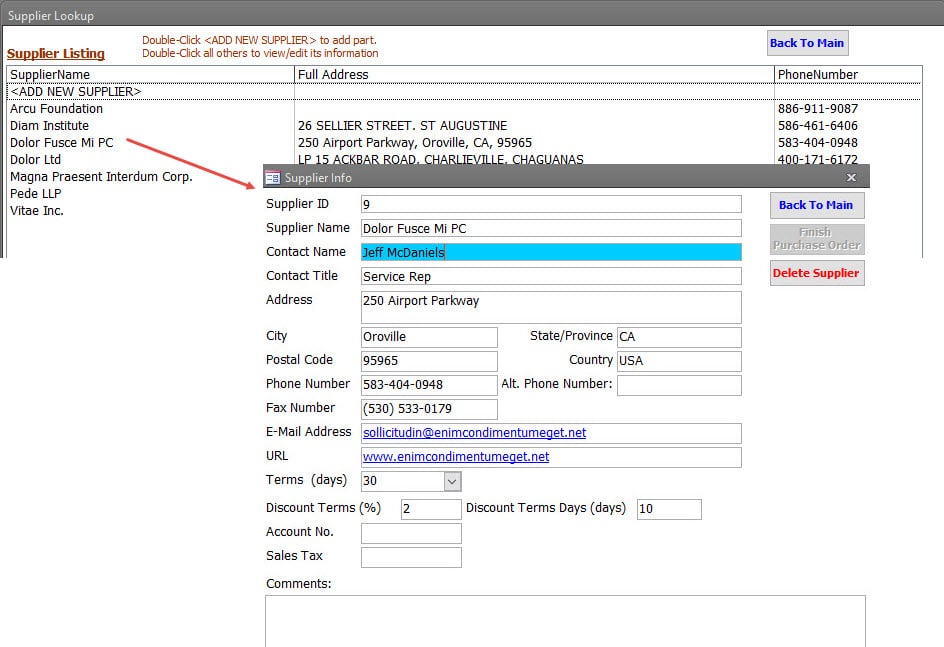

Supplier Listing and Detail Easily search Suppliers. |

|

- Work Order Module

- Work Orders

- Item Master

- Part Library

- Approved Manufactures List

- Purchase History

- Outstanding Purchase Orders

- Part Inventory

- Work Order Information

- Equipment Usage

- Purchase Orders

- Purchase Order Listing

- Purchase Order Detail

- Suppliers

- Supplier Details

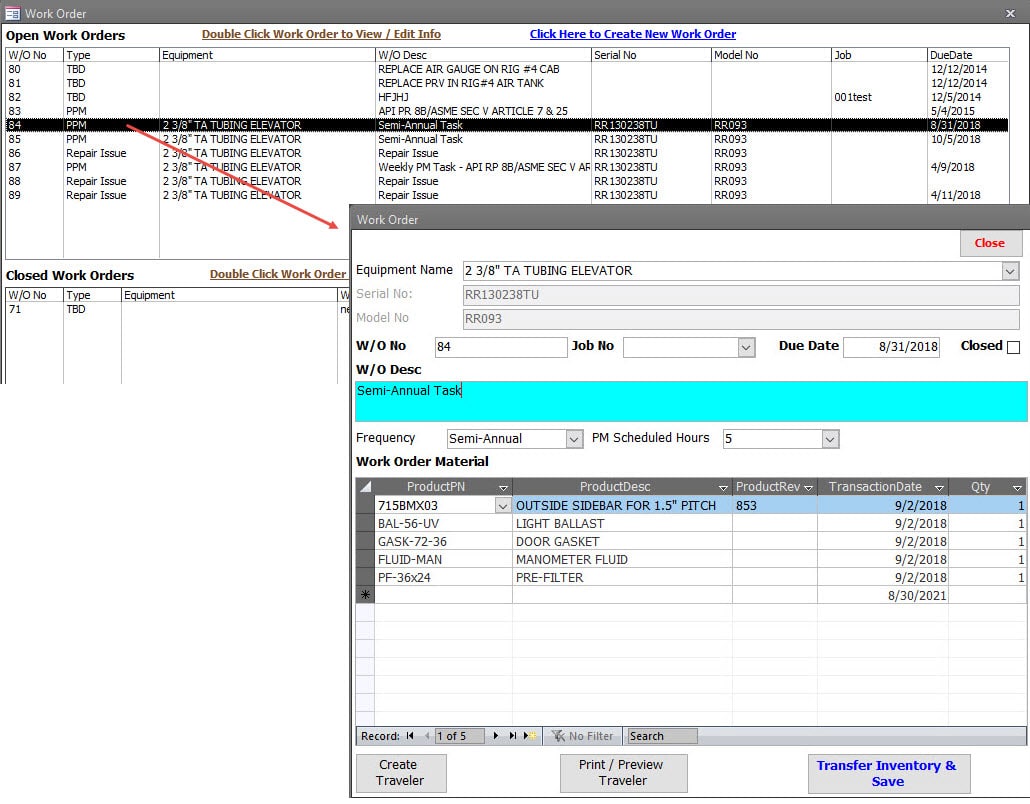

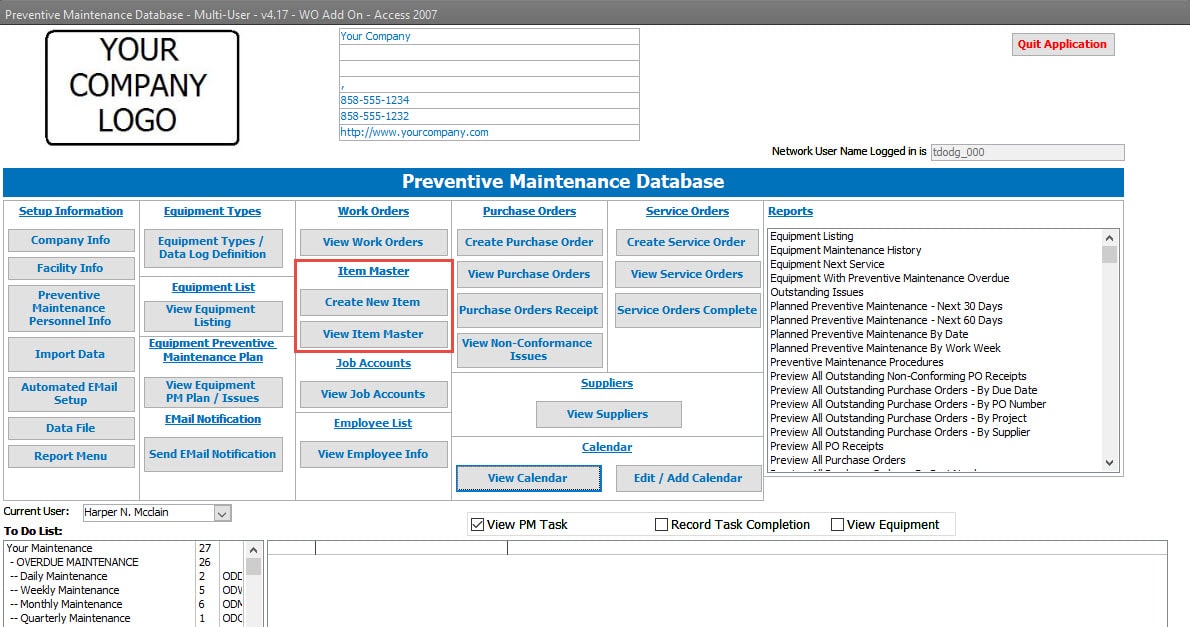

Work Order Module

The optional Work Order Module for Preventive Maintenance software includes creating Work Orders.

Work Orders capture material (inventory) and labor costs of each planned and unplanned preventive maintenance event.

Also included is an Item Master, which is used to manage the inventory in support of the Preventive Maintenance program. This inventory includes consumables, spare parts, and other materials needed to support the program.

A Purchase Order module is included to manage the purchasing and receipt of materials and goods. In addition, a purchase order receipt process ensures that the inventory quantities are accurate.

A Supplier module manages the suppliers needed to support the Preventive Maintenance program.

Work Orders

Work Orders are linked to a specific maintenance event, whether planned or unplanned.

Captures the Material consumed and automates inventory levels based on the quantities used.

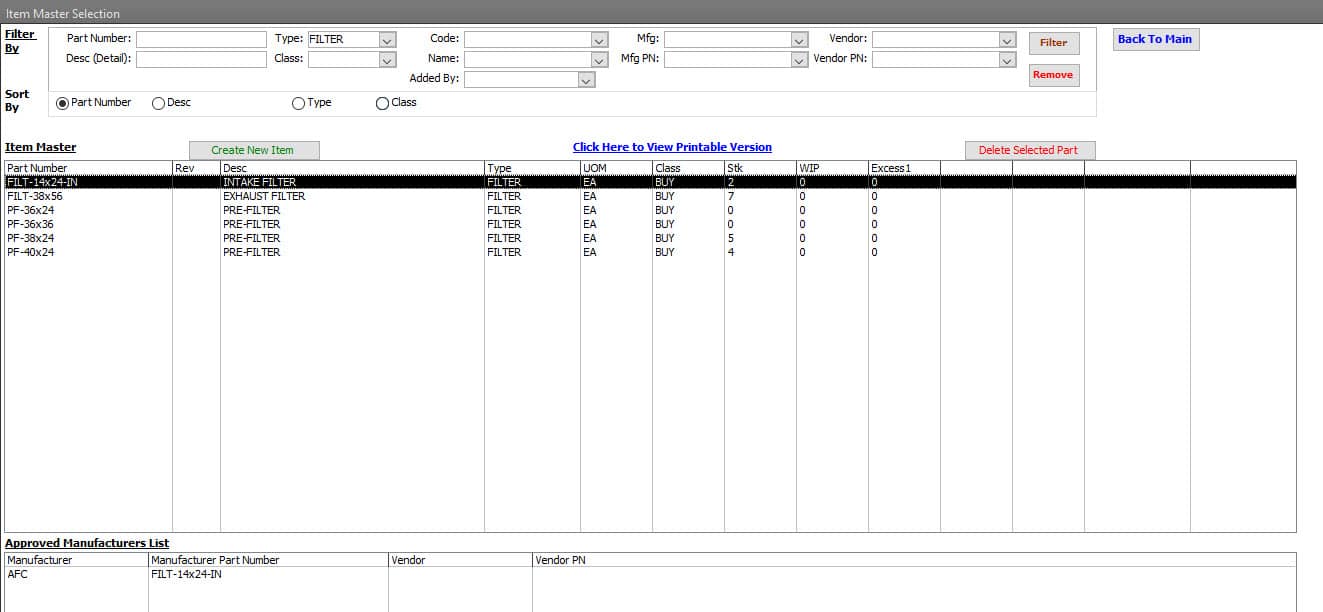

Item / Part / Material Master

The Item Master section of the Work Order Module is used to create and manage all of the part libraries for all the materials, goods, and consumables used in support of the Preventive Maintenance program.

Part Library / Listing

Easily search part library using various fields and combinations of those fields.

For example, view Inventory levels and Manufacture and Manufacture part numbers.

Part Approved Manufactures List

Each Item can have an unlimited number of acceptable manufacturer and vendor part numbers. Additionally, each Supplier / Vendor may have their part numbers for the same part across the Supply Chain.

Vendor Part Numbers are what is added to the Purchase Orders.

Part Purchase Order History

Easily see all of the Purchase Order history of the part.

View Pricing, Quantities Ordered, Suppliers and Order Dates.

Get started

Part Outstanding Purchase Orders

Easily View the Outstanding Purchase Orders for the part.

In addition, view Pricing, Quantities Ordered, Suppliers, and Order Dates.

Get started

Part Work Order Information

Easily View the Work Orders of the Part, the Work Order Information, and the Quantities consumed.

Get started

Part Where-Used / Equipment Usage

View Where-Used for the Part.

Ideal for Spare Parts and Consumable Purchasing decisions.

Get started

Purchase Orders

The Purchase Order section of the Work Order Module is used to create and manage Purchase Orders.

Manage the receipt of goods and record any non-conforming material. Goods or services.

Get started

Purchase Order Listing

Easily search and find Purchase Orders using various fields and combinations.

Get started

Purchase Order Information and Detail

The Purchase Order contains basic information such as the Supplier / Vendor, Delivery Information, Part Numbers, Quantity, and Unit Costs.

The preferred Shipping Method, Payment Terms, and Contact Information are also available when necessary.

An unlimited number of line items can be ordered with unlimited partial and complete receipts per line item.

Get started

Suppliers

The Supplier section of the Work Order Module is used to create and manage Suppliers in support of the Purchase Order and Service Order sections.

Get started

Supplier Listing and Detail

Easily search Suppliers.

Each Supplier contains specific information such as Name, Address, Contact Information, Payment Terms, Account No, and Sales Tax rate.

Get started

|

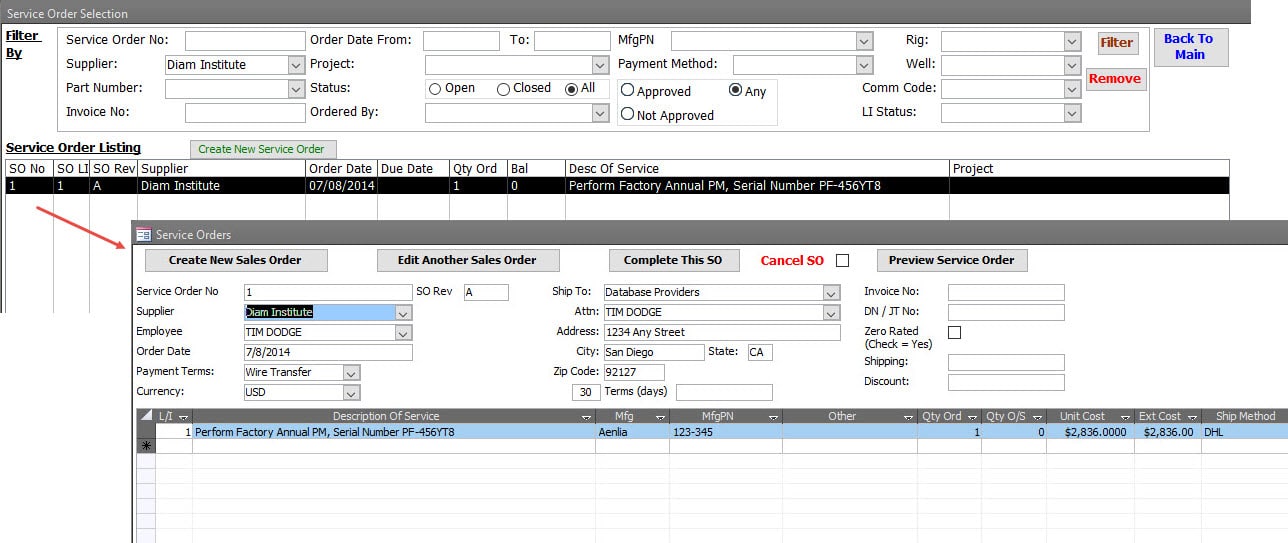

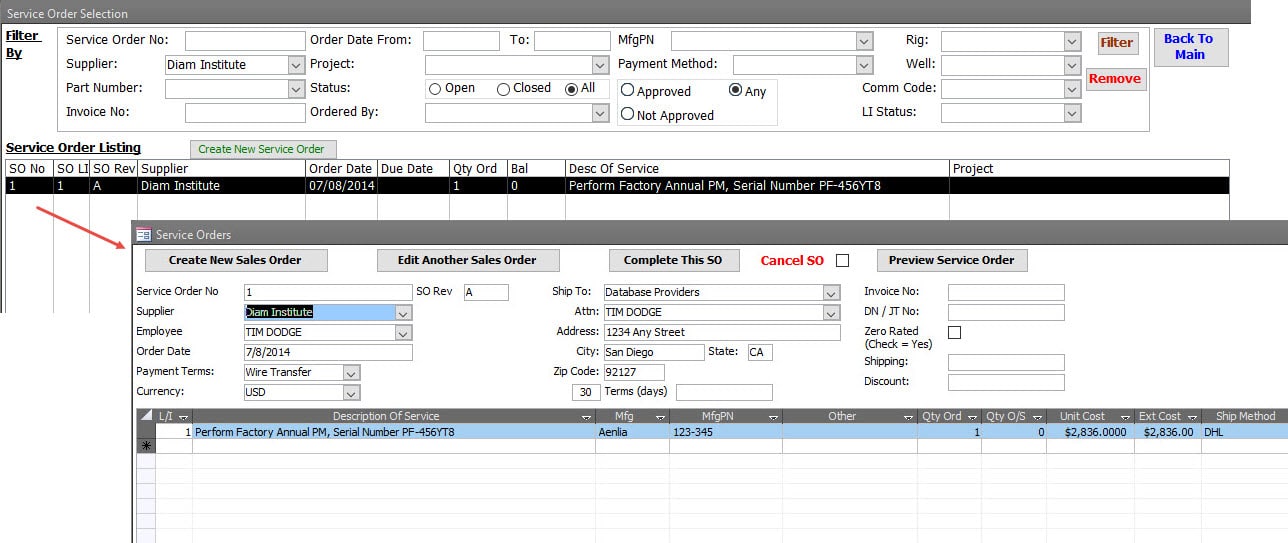

Service Orders The optional Service Order Module for Preventive Maintenance software includes creating and managing Service Orders. |

|

|

Service Order Listing and Information Service Orders are linked to a specific equipment or asset. |

|

|

Suppliers The Supplier section of the Service Order Module is used to create and manage Suppliers in support of the Purchase Order and Service Order sections. |

|

|

Supplier Listing and Detail Easily search Suppliers. |

|

Service Orders

The optional Service Order Module for Preventive Maintenance software includes creating and managing Service Orders.

Service Orders are used to provide Third Party Suppliers with a request for service to be performed on equipment or asset.

Service Order Listing and Information

Service Orders are linked to a specific equipment or asset.

As with Purchase Orders, primary fields include the Supplier, Contact Information, the Service Request to be performed, Pricing, and the Need Date.

Get started

Suppliers

The Supplier section of the Service Order Module is used to create and manage Suppliers in support of the Purchase Order and Service Order sections.

Supplier Listing and Detail

Easily search Suppliers.

Each Supplier contains specific information such as Name, Address, Contact Information, Payment Terms, Account No, and Sales Tax rate.

|

Setup The Preventive Maintenance setup section manages the global setting of the software. |

|

|

Company Information Adding your company’s information and logo personalizes the Preventive Maintenance Software. |

|

|

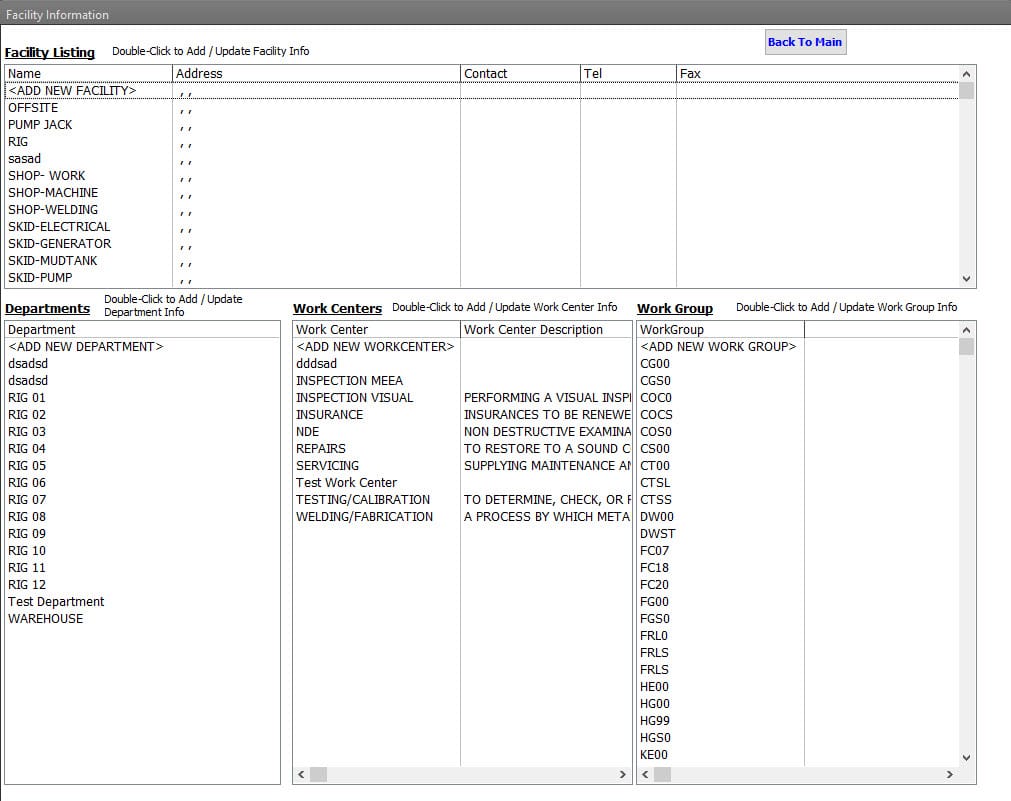

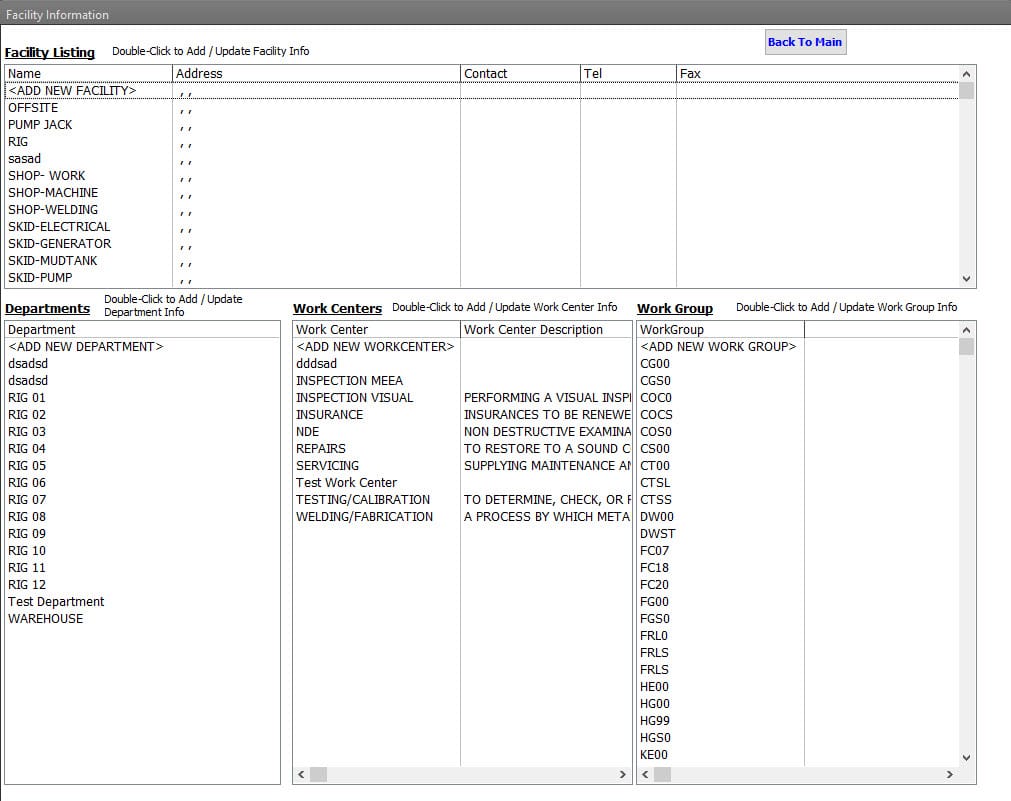

Facility Information The facility, department, work center, and workgroup can identify all company assets. Unlimited facilities, departments, work centers, and work groups can be created and managed through the setup area. |

|

|

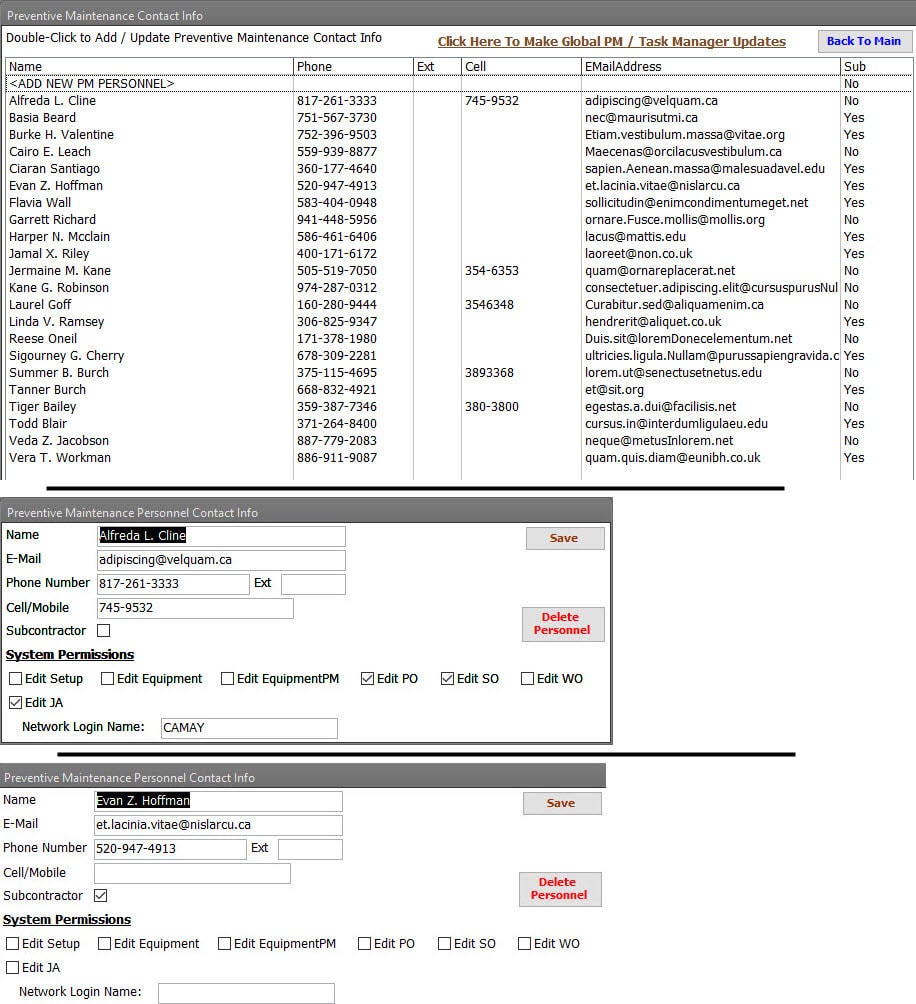

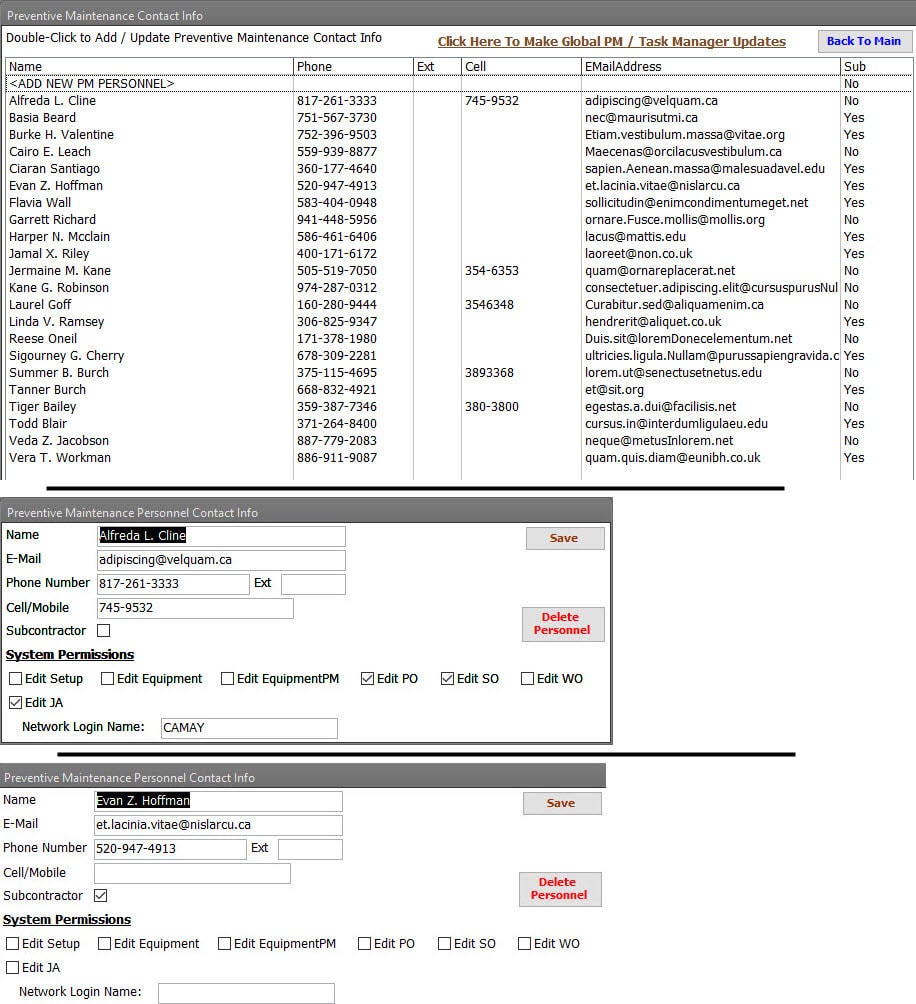

Preventive Maintenance Personnel Information All parties involved within the organization’s Preventive Maintenance program are managed within the Setup area. Parties can be either internal personnel connected to the PM program or external parties such as Vendors or Suppliers that may perform the PM tasks. Each internal personnel can be assigned permissions within this Preventive Maintenance software. |

|

|

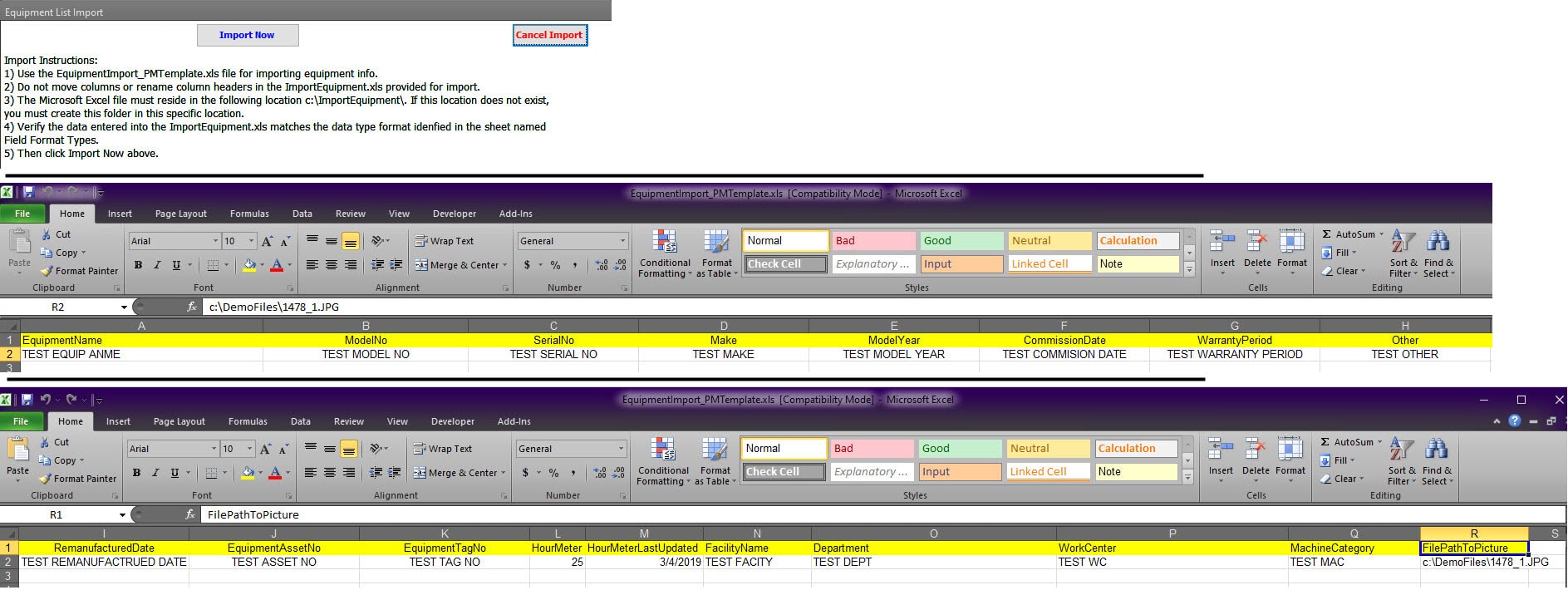

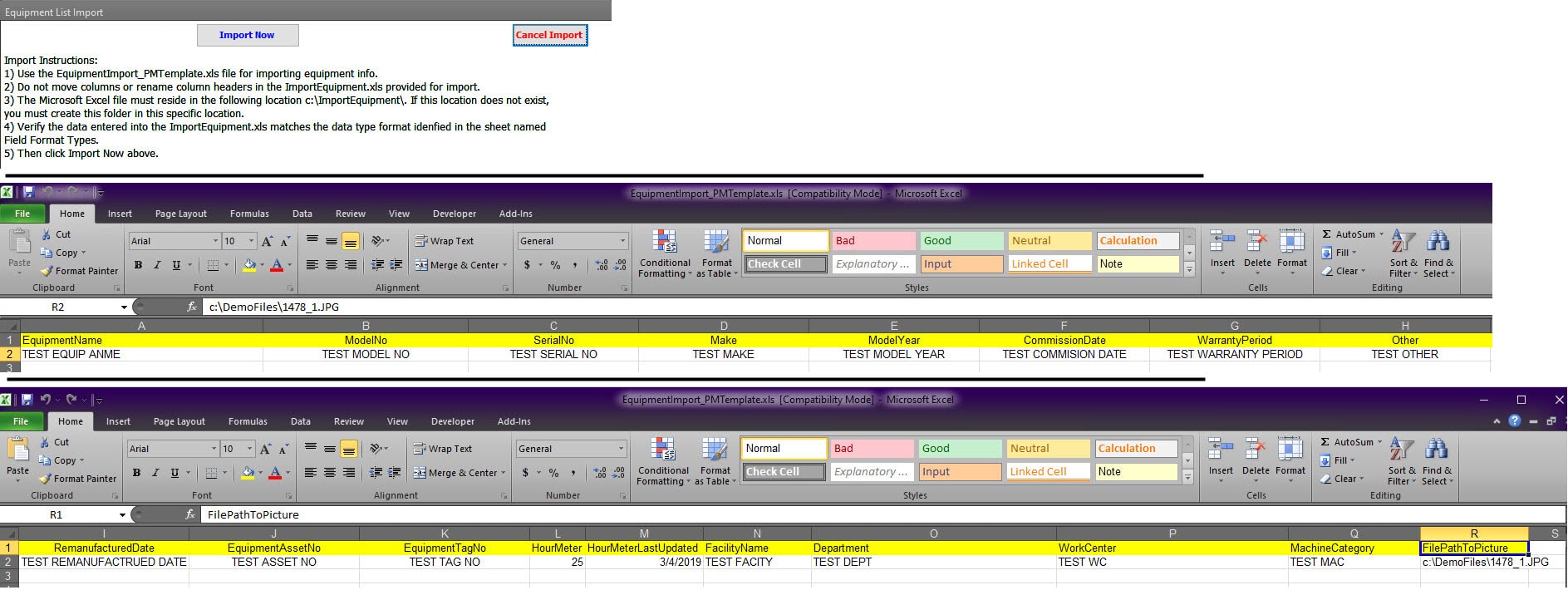

Importing of Equipment and Assets Importing existing assets is simple. First, an import template is provided, which is used to import assets into the Preventive Maintenance software. The import template includes the most common fields defining an asset, including Asset Name, Serial Number, Model Number, Tag Number, and Asset Number. When the Work Order module is purchased, importing part master, inventory, work orders, and suppliers is available. |

|

Setup

The Preventive Maintenance setup section manages the global setting of the software.

Your organization’s information, unique facilities, work centers, and departments are all managed under Setup.

The parties involved in carrying out the PM tasks and schedule, both internal and external, are also part of the setup.

Importing assets, part numbers, suppliers, inventory, and work orders are all accomplished with setup, setting up the Email connection, and automated Email frequency.

Although the program does come with numerous reports, any new reports created by the organization can be added to the report listing, which is also managed in the setup section.

Get started

Company Information

Adding your company’s information and logo personalizes the Preventive Maintenance Software.

Facility Information

The facility, department, work center, and workgroup can identify all company assets. Unlimited facilities, departments, work centers, and work groups can be created and managed through the setup area.

Preventive Maintenance Personnel Information

All parties involved within the organization’s Preventive Maintenance program are managed within the Setup area. Parties can be either internal personnel connected to the PM program or external parties such as Vendors or Suppliers that may perform the PM tasks.

Each internal personnel can be assigned permissions within this Preventive Maintenance software.

Importing of Equipment and Assets

Importing existing assets is simple. First, an import template is provided, which is used to import assets into the Preventive Maintenance software. The import template includes the most common fields defining an asset, including Asset Name, Serial Number, Model Number, Tag Number, and Asset Number.

When the Work Order module is purchased, importing part master, inventory, work orders, and suppliers is available.